Photoelectric weft detection device for water jet loom

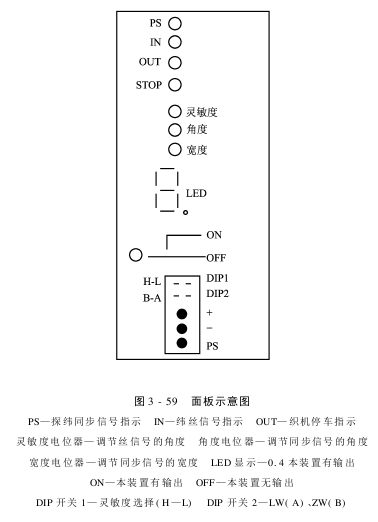

When water-jet looms use high-voltage discharge weft detection devices to weave twisted fabrics, they have very high requirements for water quality. They need to invest in a set of water purification equipment to reduce conductivity, which limits the adaptability of water-jet looms to fabrics. The complete electric weft detection device can solve this problem. The fully electric weft detection device adopts advanced devices such as SMD components and fully conductive fibers that are widely used in the world, making the product small in size, low in failure rate, and reliable in operation. 1. Introduction to the principle: This device uses a probe with fully conductive fibers to detect the weft. The detection device amplifies the detection signal and compares it with the weft detection angle signal of the loom, thereby sending the shutdown or operation signal to the loom. The main control panel completes the weft detection. 2. Panel diagram (Figure 3-59)  3. Debugging (1) Adjust DIP switch 2 to position A , and set the loom synchronization proximity switch position to about 270°~320°. (2) Sensitivity adjustment: Turn off the weft detection switch, start the loom, adjust the sensitivity potentiometer so that the LED digital tube displays 5, and then adjust 1 to 2 levels in the opposite direction. (3) Adjust the potentiometer according to the vehicle speed, 400~600r/min, usually around 11~12 o’clock. 600~800r/min, adjusted around 13~14 o’clock. (4) Angle potentiometer adjustment: Adjust the potentiometer so that the LED displays 1 or 2 (it is not recommended to adjust it to 3 or 4). (5) Turn on the weft detection switch and run the loom. Note: It must be adjusted in conjunction with the machine to select the appropriate water volume, pressure, and spray angle to make the LED display numbers stable.

3. Debugging (1) Adjust DIP switch 2 to position A , and set the loom synchronization proximity switch position to about 270°~320°. (2) Sensitivity adjustment: Turn off the weft detection switch, start the loom, adjust the sensitivity potentiometer so that the LED digital tube displays 5, and then adjust 1 to 2 levels in the opposite direction. (3) Adjust the potentiometer according to the vehicle speed, 400~600r/min, usually around 11~12 o’clock. 600~800r/min, adjusted around 13~14 o’clock. (4) Angle potentiometer adjustment: Adjust the potentiometer so that the LED displays 1 or 2 (it is not recommended to adjust it to 3 or 4). (5) Turn on the weft detection switch and run the loom. Note: It must be adjusted in conjunction with the machine to select the appropriate water volume, pressure, and spray angle to make the LED display numbers stable.

AAANHJJGHSFW

Disclaimer:

Disclaimer: Some of the texts, pictures, audios, and videos of some articles published on this site are from the Internet and do not represent the views of this site. The copyrights belong to the original authors. If you find that the information reproduced on this website infringes upon your rights, please contact us and we will change or delete it as soon as possible.

AA