Control system electronic weft storage device

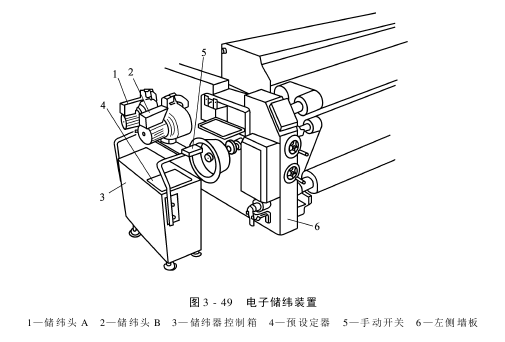

The electronic weft storage device can wrap the weft around the length measuring drum according to pre-set data and place the weft quantitatively. This device consists of weft storage control, length measurement control, weft selection control, yarn presser control, steering water valve control and water replenishment valve control. (1) Weft storage control: In order to prevent insufficient weft storage when the loom is started, the necessary amount of weft must be wound in advance. (2) Length measurement control: Use electrical signals to control the suction and disconnection of the solenoid valve (finger stick) to control the length of each weft. (3) Weft selection control: The weft selection command device carries out two-color or three-color weft selection instructions to select the weft. (4) Yarn presser control: controlled by the terminal, the weft is clamped or released according to the preset angle. (5) Steering water valve control: Same as weft selection control, and synchronized with color selection. (6) Water replenishment valve control: After the loom stops, replenish water to the water pump manually or automatically. The electronic weft storage device usually consists of a weft storage head, a control box, a preset device and a manual switch. See Figure 3-49 for details. At present, most domestic water-jet looms are generally equipped with Kasuga weft feeder (PAW) and ROJ weft feeder (IRO). In recent years, many domestic manufacturers have also launched their own products, but the basic models are still the above two. The two types of weft feeders are introduced separately below. 1.PAW weft feeder The shape and structure of the weft feeder head are shown in Figure 3-50.

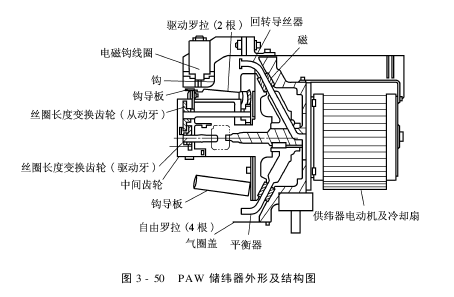

Theweftfeedershowninthepictureisofstandardstructure,alsoknownasrollertype.Itconsistsof2drivingrollersand4freerollers.Thefreerollercanbeusedtoadjustthewindinglength(yarnpreparationlength)andwindingtension.Changingtheradialsizeorangleofthefreerollercaneasilyadapttovariousfibersordifferentdoorwidths.Therollertypeweftfeederhasobviousadvantageswhenusedfortwistingyarn.Figure3-51showsthestructureoftherollertypeweftfeeder.Themovementoftheweftstorageheadshouldbesynchronizedwiththestartandstopoftheloom.Whentheloomisstartedandrotatestotheangleofwaterdischargefromthenozzle,thefingerrod(electromagnetichook)oftheweftfeederislifted,andtheyarnpresserisalsoreleased.Thewaterflowinthenozzlebringstheweftout,completingtheweftinsertionprocess.Whentheweftthreadreachestheend,thefingerstickisloweredandtheyarnpresserisclosedtopreventtheweftthreadfromslackening.Here,theattractionordisconnectionofthefingerrodandtheyarnpresseriscloselyrelatedtotheoperatingangleoftheloom.Therefore,theweftfeedermustrequiretheloomtoprovideoperationsignalsandreferencesignals,AweftfeedersignalandBweftfeedersignal.Theabovesignalsaregenerallycontrolledbythreeproximityswitches.TheinstallationanddebuggingmethodisshowninFigure3-52.

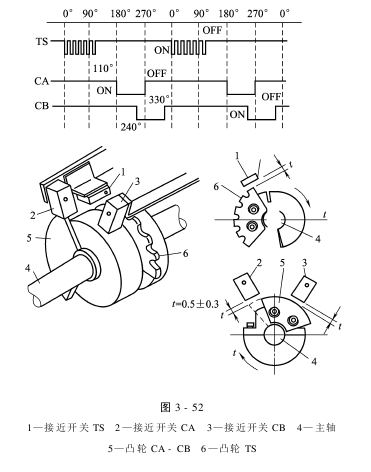

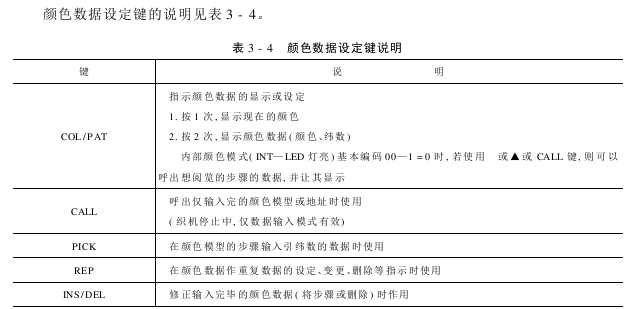

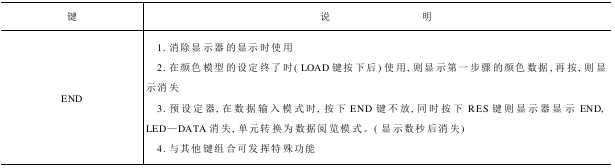

Theweftfeedershowninthepictureisofstandardstructure,alsoknownasrollertype.Itconsistsof2drivingrollersand4freerollers.Thefreerollercanbeusedtoadjustthewindinglength(yarnpreparationlength)andwindingtension.Changingtheradialsizeorangleofthefreerollercaneasilyadapttovariousfibersordifferentdoorwidths.Therollertypeweftfeederhasobviousadvantageswhenusedfortwistingyarn.Figure3-51showsthestructureoftherollertypeweftfeeder.Themovementoftheweftstorageheadshouldbesynchronizedwiththestartandstopoftheloom.Whentheloomisstartedandrotatestotheangleofwaterdischargefromthenozzle,thefingerrod(electromagnetichook)oftheweftfeederislifted,andtheyarnpresserisalsoreleased.Thewaterflowinthenozzlebringstheweftout,completingtheweftinsertionprocess.Whentheweftthreadreachestheend,thefingerstickisloweredandtheyarnpresserisclosedtopreventtheweftthreadfromslackening.Here,theattractionordisconnectionofthefingerrodandtheyarnpresseriscloselyrelatedtotheoperatingangleoftheloom.Therefore,theweftfeedermustrequiretheloomtoprovideoperationsignalsandreferencesignals,AweftfeedersignalandBweftfeedersignal.Theabovesignalsaregenerallycontrolledbythreeproximityswitches.TheinstallationanddebuggingmethodisshowninFigure3-52.  Proximityswitchadjustment:ThecolorconversionsignalisoutputbyproximityswitchesTS1,CA2,andCB3.TSistheswitchfortimingreference,CAandCBareproximityswitchesforcolorswitching.Thegapbetweentheproximityswitchandthecamisadjustedto0.5±0.3mm;oncethecamisclosetotheproximityswitch,itscorrespondingLEDlightwilllightup.Theoperationoftheweftfeeder,includingtheparametersettingsormodificationsofthefingerbar,yarnpresserandrotaryvalve,etc.,arealloperatedonthepresetdeviceontheweftfeedercontrolbox.Thereare3typesofpresetkeys,includingcommandkeys,colordatasettingkeys,andbasickeys,totaling30.SeeTable3-3forthedescriptionofthecommandkeys.

Proximityswitchadjustment:ThecolorconversionsignalisoutputbyproximityswitchesTS1,CA2,andCB3.TSistheswitchfortimingreference,CAandCBareproximityswitchesforcolorswitching.Thegapbetweentheproximityswitchandthecamisadjustedto0.5±0.3mm;oncethecamisclosetotheproximityswitch,itscorrespondingLEDlightwilllightup.Theoperationoftheweftfeeder,includingtheparametersettingsormodificationsofthefingerbar,yarnpresserandrotaryvalve,etc.,arealloperatedonthepresetdeviceontheweftfeedercontrolbox.Thereare3typesofpresetkeys,includingcommandkeys,colordatasettingkeys,andbasickeys,totaling30.SeeTable3-3forthedescriptionofthecommandkeys.

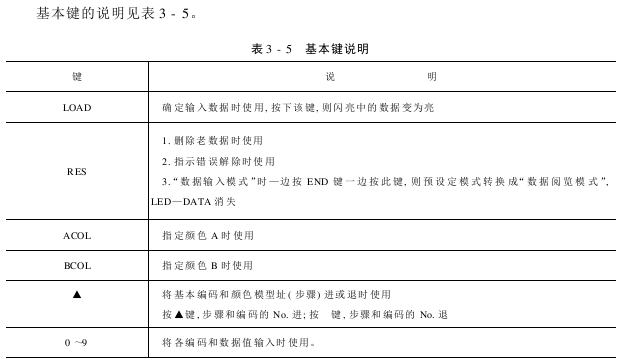

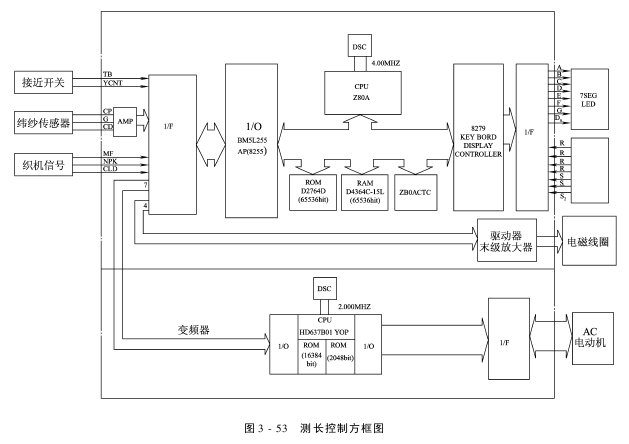

The control block diagram of the PAW weft feeder is shown in Figure 3-53. 2.IRO weft storage device TDS/Z is a weft storage device with separated yarn loop gaps that can be installed on air-jet and water-jet looms. It is suitable for a wide range of spinning yarns. Ranging from 20dtex (fine yarn) to 120tex (roving yarn). It places the weft according to the required weft length. The appearance of the weft storage head is shown in Figure 3-54. The functions of the IRO weft feeder: (1) The yarn winding disc can be set to rotate in the S or Z direction, depending on the twist direction of the spinning yarn. (2) The weft yarn is stored into separate yarn loops and the yarn separation distance is adjustable [Note: The yarn loop interval can be set between 0.7mm (small diameter yarn storage drum) and 2.2mm (large diameter yarn storage drum) ]. (3) The released yarn loop is tested by the electric tube. (4) The adjustment of weft length [LENGTH] is preset by adjusting the diameter of the yarn storage drum and setting the number of yarn loops to be released (range of weft length: 64 ~ 520cm).

The control block diagram of the PAW weft feeder is shown in Figure 3-53. 2.IRO weft storage device TDS/Z is a weft storage device with separated yarn loop gaps that can be installed on air-jet and water-jet looms. It is suitable for a wide range of spinning yarns. Ranging from 20dtex (fine yarn) to 120tex (roving yarn). It places the weft according to the required weft length. The appearance of the weft storage head is shown in Figure 3-54. The functions of the IRO weft feeder: (1) The yarn winding disc can be set to rotate in the S or Z direction, depending on the twist direction of the spinning yarn. (2) The weft yarn is stored into separate yarn loops and the yarn separation distance is adjustable [Note: The yarn loop interval can be set between 0.7mm (small diameter yarn storage drum) and 2.2mm (large diameter yarn storage drum) ]. (3) The released yarn loop is tested by the electric tube. (4) The adjustment of weft length [LENGTH] is preset by adjusting the diameter of the yarn storage drum and setting the number of yarn loops to be released (range of weft length: 64 ~ 520cm).

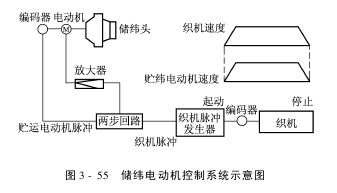

(5) Two-way communication from the website to the loom control panel. Set working parameters directly through the loom control panel or through the Roj handheld terminal. (6) Through the completion tube or RojTFE4 spinning yarn detector installed in SuperElf, the action of weft breaking can be controlled at the input. (7) Loom stop function. The schematic diagram of the engine control system is shown in Figure 3-55.

(5) Two-way communication from the website to the loom control panel. Set working parameters directly through the loom control panel or through the Roj handheld terminal. (6) Through the completion tube or RojTFE4 spinning yarn detector installed in SuperElf, the action of weft breaking can be controlled at the input. (7) Loom stop function. The schematic diagram of the engine control system is shown in Figure 3-55.

AAAKY,7II56U65

Disclaimer:

Disclaimer: Some of the texts, pictures, audios, and videos of some articles published on this site are from the Internet and do not represent the views of this site. The copyrights belong to the original authors. If you find that the information reproduced on this website infringes upon your rights, please contact us and we will change or delete it as soon as possible.

AA