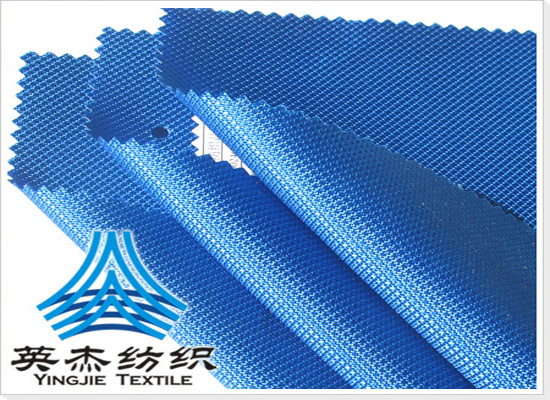

Waterproof Oxford cloth

Waterproof Oxford Cloth

Oxford cloth

Oxford cloth is a new type of fabric with multiple functions and wide uses. The main varieties on the market include: set grid, full elastic, nylon, teguet and other varieties. According to the ingredients, they mainly include: 100% cotton, 100% polyester, 100% polyester, nylon,

Oxford cloth characteristics:

1. High strength, impact resistance is 4 times higher than nylon and 20 times higher than viscose fiber.

2. Good elasticity. The elasticity is close to that of wool. When stretched by 5% to 6%, it can almost completely recover. The wrinkle resistance exceeds other fibers, that is, the fabric does not wrinkle and has good dimensional stability. The elasticity is 2 to 3 times higher than nylon.

3. Good heat resistance.

4. Good water absorption.

5. Good wear resistance. The wear resistance is second only to nylon with good wear resistance, and better than other natural fibers and synthetic fibers.

6. Good light resistance. Light resistance is second only to acrylic fiber.

7. Corrosion resistance. Resistant to bleach, oxidants, hydrocarbons, ketones, petroleum products and inorganic acids. Resistant to dilute alkali and not afraid of mold, but hot alkali can decompose it.

Waterproofing treatment classification

1. Add auxiliaries in the dyeing factory: waterproofing is just a post-processing. As long as you have requirements, any fabric can be treated with this treatment, and the products will have a waterproof effect. Just add a little waterproofing agent when finalizing in the dyeing factory to achieve the effect. !

2. Coating factory coating: a fabric treated with a special process. It can form a uniform layer of covering glue on the surface of the fabric to achieve waterproof, windproof and other functions. The coating method includes wet method and dry method. The difference is that the primer and coating pass through the water tank, and the glue surface is solidified under the action of water. Other physical test standards are consistent with it. Wet coating fixes polyurethane and adhesive on the surface of the fabric through mechanical action, which is environmentally friendly. The adhesive surface can be white, silver, transparent, black, etc.

After the wet coating process is completed, the following physical properties are tested.

(1) Waterproof: American standard test AATCC-22: 100 points (level 5) before washing, 90 points (level 4) after washing 10 times, and 80 points (level 3) after washing 20 times.

(2) Tear strength: After multiple dry coating processes, especially calendering, the tear strength will be greatly reduced, which will weaken the wear resistance and damage resistance of the garment. If it cannot meet the tear requirements of the same variety , consider adding an anti-tear agent during the processing to improve the tear strength of the fabric. Of course, this anti-tear agent is an environmentally friendly material.

(3) Coating uniformity: For fabric coating, put PU glue on the cloth surface and use a scraper to evenly distribute it. You can use a weighing machine to take a piece on the left, middle and right sides of the cloth and weigh it, and you will know the weight of the left, middle and right pieces. Whether the value is qualified.

(4) Rain: American standard test AATCC-35. For this test, a cloth is used to fix the position, and dripping water is poured on the surface of the fabric. Generally, if it is less than 1g, it is qualified.

(5) Water pressure resistance: American standard test standard AATCC-127 Japanese standard test JIS-L 1092B, water pressure resistance is expressed in mmH2O.

(6) Water permeability: cup method: American standard ASTM E-96 A, C, E; Japanese standard JIS L-1099 A1; inverted cup method: American standard ASTM-E96, Japanese standard test JIS-L 1099B1; for water permeability g/m2/24hours expressed.

(7) Adhesive surface peeling fastness: American standard AATCC-135 test, no separation after continuous water washing for 24 hours.

Is nylon or polyester better for waterproofing?

It depends on what your needs are and what fabrics you want to use for the finished product.

Nylon is the name of a raw material, and Oxford cloth is the name of a fabric variety.

There is nylon oxford cloth. Available in polyester oxford fabric. Nylon also has nylon yarn, etc. It depends on what product characteristics you have.

Application:

Waterproof Oxford cloth is widely used in sportswear, down jackets, rainproof parkas, jackets, tents, shoes and socks, curtains, bags, as well as ski shirts, mountaineering clothes, windbreakers, etc. with advanced waterproof and moisture-permeable functions. It can also be used in national defense, navigation, fishing, offshore oil wells, transportation and other fields. Waterproof coating series fabrics have multiple functions such as windproof, waterproof, and moisture permeability. Specially used for making all kinds of bags, flood and rainproof supplies, etc.

Disclaimer:

Disclaimer: Some of the texts, pictures, audios, and videos of some articles published on this site are from the Internet and do not represent the views of this site. The copyrights belong to the original authors. If you find that the information reproduced on this website infringes upon your rights, please contact us and we will change or delete it as soon as possible.

AA