150D polyester Oxford cloth

150D polyester Oxford cloth

Process design and implementation

1. First introduction to fabric

2. 150D polyester oxford cloth pre-treatment process

2.1. Desizing, refining and relaxing processing

2.2. Preforming

2.3. Alkali reduction processing

3. Performance testing

3.1. Desizing rate

3.2. Reduction rate

3.3. Dimensional stability

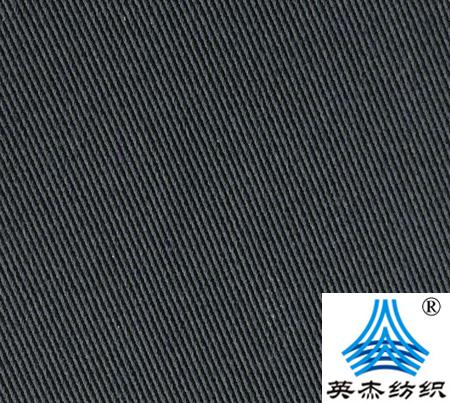

Structural features: Weft-heavy flat or square weave is used, with combed fine yarns as double warps interwoven with thicker weft yarns. Style features: easy to wash and quick to dry, soft to the touch, good hygroscopicity, comfortable to wear, and natural luster.

Main uses:

1. Plaid Oxford cloth, specially used for making bags.

2. Nylon Oxford cloth, mainly used to make flood prevention supplies.

3. Fully elastic Oxford cloth, mainly used for making bags.

4. Teague Oxford cloth, mainly produces various bags.

5. Weft Oxford cloth, mainly used to make various bags.

Temperature: 190 degrees Celsius

Time: 30s

Purpose: Eliminate fabric wrinkles and improve fabric dimensional stability.

Alkali reduction processing:

Drugs: 30% caustic soda 5g/L

Liquor ratio: 1:50

Accelerator (1227)1g/L

Refining agent: 0.5g/L

Temperature: 100 degrees Celsius

Time: 60min

Purpose: To give the fabric a soft feel, soft luster, and improve hangability and water retention.

Performance testing:

Desizing rate:

The weight of the fabric before desizing is 22g, and the weight of the fabric after desizing is 21.72g

Desizing rate = (fabric weight before desizing – fabric weight after desizing)/

Fabric weight before desizing×100%

Desizing rate=(22-21.72)/22×100%=1.27%

Reduction rate:

The weight of the fabric before alkali reduction is 9.48g, and the weight of the fabric after alkali reduction is 9.08g

Weight reduction rate = (fabric weight before alkali weight reduction – fabric weight after alkali weight reduction)/fabric weight before alkali weight reduction × 100%

Alkali reduction rate = (9.48-9.08)/9.48×100%=4.22%

Dimensional stability:

Shrinkage:

Shrinkage before heat setting = (10-9.525)/10×100%=4.75%

Shrinkage after heat setting = (10-9.945)/10×100%=0.55%

The shrinkage rate after setting is obviously smaller than that before heat setting, so the fabric after setting is relatively stable. htK

Disclaimer:

Disclaimer: Some of the texts, pictures, audios, and videos of some articles published on this site are from the Internet and do not represent the views of this site. The copyrights belong to the original authors. If you find that the information reproduced on this website infringes upon your rights, please contact us and we will change or delete it as soon as possible.

AA