Application areas of coated fabric

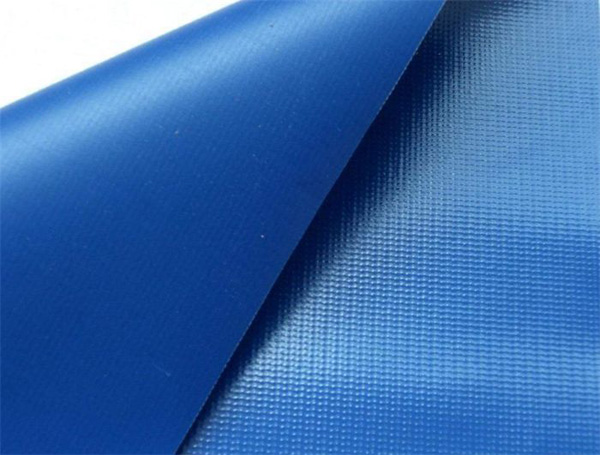

Coated fabric is a kind of fabric treated with special technology. It is to use solvent or water to dissolve the required coating particles (including PU glue, A/C glue, PVC, PE glue) into a saliva-like shape, and then use a certain method (cylindrical screen, scraper or roller) to evenly It is coated on the fabric (including cotton, polyester, nylon and other base materials), and then fixed by the temperature in the oven to form a uniform layer of covering glue on the surface of the fabric, thereby achieving waterproof, windproof, breathable and other functions.

The current types of coating finishing are roughly as follows

1. PA coating

Also called AC glue coating, that is, acrylic coating, it is a common coating at present. After coating, it can increase the feel, windproof and drape.

2. PU coating

That is, polyurethane coating. After coating, the fabric feels plump, elastic, and has a filmy feel on the surface.

3.:Anti-velvet coating

It refers to the anti-down coating. After coating, it can prevent down from running away and is suitable for making down jacket fabrics. But now, any PA coating with water pressure requirements is also called anti-velvet coating.

4. PA white glue coating

That is, coating a layer of white acrylic resin on the surface of the fabric can increase the covering rate of the fabric, make it opaque, and make the color of the fabric more vivid

5. PU white glue coating

That is, a layer of white polyurethane resin is coated on the surface of the fabric. The function is basically the same as that of PA white glue, but the PU white glue has a fuller feel after application, the fabric is more elastic, and the fastness is better.

6. PA silver glue coating

That is to apply a layer of silver-white glue on the surface of the fabric to make the fabric have light-shielding and radiation-proof functions. It is generally used in curtains, tents, and clothing.

7. PU silver glue coating

The basic functions are the same as PA silver glue coating. However, PU silver-coated fabrics have better elasticity and better fastness. For tents and other fabrics that require high water pressure, PU silver-coated fabrics are better than PA silver-coated fabrics.

8. Pearlescent coating

By applying a pearlescent coating on the surface of the fabric, the surface of the fabric is given a pearl-like luster, which can be silvery white or colored. It makes a very beautiful costume. There are also PA pearlescent and PU pearlescent. PU pearlescent is smoother and brighter than PA pearlescent, has a better film feel, and is also known as “pearl film”.

9. Flame retardant coating

It uses flame-retardant coating glue to coat the surface of ordinary fabrics or cotton flame-retardant fabrics to achieve a certain flame-retardant and waterproof effect. This kind of coated flame-retardant fabrics are often used in tents and car clothing. At present, it is mainly developed and promoted by Xinxing Company.

1. Application fields of coated fabric

1. Luggage fabric

2. Military tent

3. Airbag cloth

4. Outdoor sports and leisure (ski clothing, jackets, mountaineering clothing, raincoats, down jackets, mountaineering bags)

5. Protective workwear (fluorescent HV, flame retardant FR, anti-static ANTI-STATIC, cold and rain-resistant AGAINSTCOLD&RAIN)

6.Car clothing

7. Curtains

8. Sleeping bag

9. Spinnaker

10. Paragliding

11. Hot air balloon

12.Military and police clothing (combat uniforms, training uniforms, camouflage uniforms)

13.?High-end casual wear, high-end underwear

14. Backpack 9cZ1uhoY3

Disclaimer:

Disclaimer: Some of the texts, pictures, audios, and videos of some articles published on this site are from the Internet and do not represent the views of this site. The copyrights belong to the original authors. If you find that the information reproduced on this website infringes upon your rights, please contact us and we will change or delete it as soon as possible.

AA