Detection of UV-resistant fabrics

Testing of UV-resistant fabrics

With the arrival of summer, a variety of sun protective clothing has appeared on the market. Sun protection clothing first became popular in the United States and then entered China. At first, it was mostly used in outdoor activity products, and was rarely used in ordinary clothing. Later, it was favored by many female friends.

Sun protection clothing is made of high-quality polyester fiber. The sun protection coefficient of polyester fiber is larger than that of other fibers. The sun protection coefficients of various fibers are: polyester fiber > cotton fiber > artificial cotton and silk.

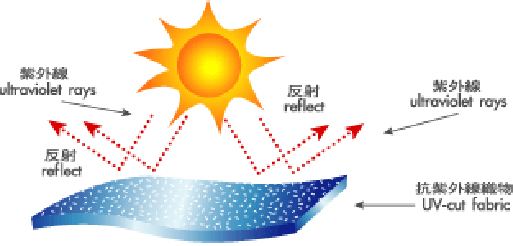

The main function of sun protection clothing is to prevent direct exposure to ultraviolet rays from the sun. Ultraviolet rays are the main cause of premature aging of the skin, causing photoaging of the skin and even skin cancer, which endangers human health.

Most of the fabrics of sun protection clothing are anti-UV fabrics with sunscreen additives added to them. Some sun protection fabrics use ceramic micropowder combined with fibers to increase the reflection and scattering of ultraviolet rays on the surface of the clothing and prevent ultraviolet rays from penetrating the fabric and damaging human skin.

At present, there are roughly four ways to improve the UV resistance of textiles. One is to directly use fibers with better UV resistance as raw materials to produce textiles, such as flax, polyester fibers, etc.; the other is to change the organizational structure of the fabric, such as adding more fabrics. The thickness, density, etc.; the third is to add ceramic particles to reflect ultraviolet rays during spinning of textile fibers to achieve the effect of ultraviolet protection; the fourth is to perform anti-ultraviolet post-finishing on the fabric, such as dipping the fabric with ultraviolet absorbers or blockers, or Anti-UV coating finishing on the surface of the fabric, etc.

Test methods for UV protection properties of textiles

At present, there is no unified international standard for testing the UV protection performance of textiles. In existing standards, testing methods for UV protection can be roughly divided into direct testing methods and instrumental testing methods. Direct testing methods include human testing method and discoloration and fading method, which are simple and fast. However, human testing method has large systematic deviation due to differences in human skin, poor reproducibility, and the testing process is harmful to the human body. Instrumental testing methods include ultraviolet intensity accumulation method, ultraviolet method and spectrophotometer method. EU standards, Australian/New Zealand standards, British standards, American AATCC standards and Chinese standards all use the spectrophotometer method. This method mainly generates ultraviolet rays with a wavelength of 290 to 400 nm through a stable UV light source, irradiates the sample through a monochromator, collects the total spectral projection rays, determines the total spectral projection ratio, and calculates the ultraviolet transmittance and Protection factor UPF value.

The UPF value is the ratio of the average effect of ultraviolet radiation when the skin is unprotected and when it is protected by fabrics. It can also be considered as the time threshold required for ultraviolet radiation to cause the skin to reach a certain damage (such as erythema, eye damage, and carcinogenic critical dose) after using textile protection. Ratio to the time threshold to reach the same level of injury without textile protection. Therefore, differences in judgment basis and differences in human skin will cause the same textile to have many different uPF values, usually represented by the UPF value of erythema.

Disclaimer:

Disclaimer: Some of the texts, pictures, audios, and videos of some articles published on this site are from the Internet and do not represent the views of this site. The copyrights belong to the original authors. If you find that the information reproduced on this website infringes upon your rights, please contact us and we will change or delete it as soon as possible.

AA