Textile UV protection performance testing standards

Textile UV protection performance testing standards

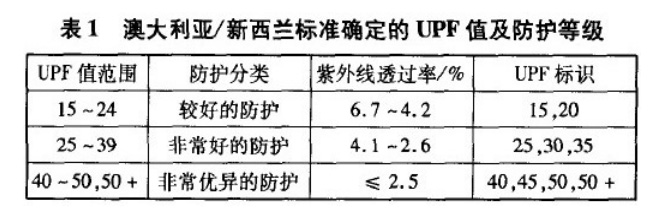

1 Australian and New Zealand Standards

The “Sun protective clothing-E-valuation and classification standard” (AS/NZS 4399, Sun protective clothing-E-valuation and classification) first developed by Australia and New Zealand is mainly used to determine protective textiles, coats and other protective equipment that are close to the skin (such as Hats) UV transmittance, and at the same time put forward requirements for anti-UV radiation labels. The standard stipulates that fabric samples must be tested in a dry and relaxed state. Each sample must be tested in 4 pieces, 2 warp and 2 weft. The sample does not need to be pre-humidified, but there are special requirements for the test environment [such as relative humidity (50% ±20%)]. Based on the ultraviolet transmittance obtained from the test, the average transmittance of uV-A and uV-B can be calculated according to wavelength, as well as the UPF value of the sample, and then corrected according to the given formula to finally obtain the UPF value of the sample. The standard also involves how to remove the impact of fabric fluorescence on test results, as well as requirements for classification of textile protection levels and labeling.

2 European standards

Different from the Australian standard, the European textile UV protection standard consists of two parts: testing and grading labeling. The fabric testing standard “Textiles-Solar UV protective properties-Part 1: Method of test for apparel fabrics” (EN13758. 1 Textiles-Solar UV protective properties-Part 1: Method of test for apparel fabrics) is based on British Standard Bs 7914-1998, issued by the United Kingdom and Northern Ireland. It was jointly revised in 2006. This standard is mainly aimed at testing the UV protection performance of clothing fabrics and is not applicable to products such as umbrellas and sunshades. Test samples are divided into two categories: homogeneous and non-homogeneous. For homogeneous fabrics, 4 pieces need to be tested. For non-homogeneous fabrics, 2 pieces should be tested according to different colors or structures. The ultraviolet transmission in the uV-A and uV-B segments is measured. rate average and UPF value. The standard specifically states that both stretched and wet states will reduce the UV protection properties of textiles.

Clothing classification and labeling standard (2006 Textiles-13 Light UV protective properties – Marking and classification of clothing) (EN 13758.2: 2003+ A1 Textiles-Solar UV protective properties-Part 2: Classifi-cation and marking of apparel1) according to the United Kingdom The standard BS 7949- 1999 was formulated and is applicable to UV-resistant clothing. This standard sets requirements for the style of test clothing. Only when the clothing fabric meets the following conditions can it be considered to have UV-resistant properties and the prescribed UV protection mark can be used.

UPF value (minimum UPF value of each fabric) >40

UV-A transmittance/% <5

3 American Standard

Different from Australian and European standards, the US textile UV protection performance standard adds pre-treatment and wet state testing content to simulate the actual application of samples. The entire standard system consists of three parts: preprocessing, testing and grading labeling.

The textile pretreatment standard “ASTM D 6544 SmndaN Practice for Preparation of Textiles Prior to Ultraviolet Transmission Testing” is applicable to fabrics or clothing labeled with sunlight or ultraviolet protection. Before testing, the textile samples were washed (40 times of hand washing, machine washing, or dry cleaning according to the garment care label), sun-dried (100 AFU of light), and chlorinated pool water washed (in accordance with AATCC 162 standards) to simulate daily use. preprocessing. This pretreatment process is equivalent to about two years of normal use of the product. Afterwards, the UV protection performance test was conducted in accordance with AATCC 183 to obtain the UV protection level of the textile after two years of use.

The UV protection performance test method standard “Textiles Transmittance or Blocking of Ultraviolet Radiation through Fabrics” (AATCC 183 Transmittance or Blocking of Erythemally Weighted Ultraviolet Radiation through Fabrics) is used to test the ability of UV protection fabrics to block or transmit UV radiation. The tested samples were divided into dry state (sample equilibrium for 4 h, 21 oC, RH 65%) and wet state (liquidation rate 150%, wrapped in plastic film). Test three times on the fabric sample in the area with high UV transmittance to obtain the average UV transmittance. Based on this, calculate the UPF value, as well as the average transmittance and UV blocking rate in the uV-A and uV-B bands. The graded labeling standard “ASTM D 6603, Standard Guide for Labeling of UV-Protective Textiles” stipulates the requirements for labeling of uV-A and uV-B ultraviolet protective textiles. Before textiles are tested for UV protection in accordance with AATCC 183, the samples can be in three states, namely, as-is (without pretreatment), once-washed samples and pre-treated samples (as required by standard ASTM D 6544). According to actual needs, measure the UPF value of the sample in different states, and then determine the UV protection level of the clothing based on the lower UPF value among the three states for labeling. The standard stipulates that the UV protection level is divided into 4 levels. Products with a UPF value lower than l5 cannot be labeled as UV protection products.

4Chinese standards

Drawing on the characteristics of Australian and European standards, my country formulated the GB/T 18830-2002 (Evaluation of UV Protection Performance of Textiles) standard in 2002, which stipulates the test methods for the sun and UV protection properties of fabrics, and the expression, evaluation and labeling of protection levels. .Like the Australian standard AS/NZS 4399, GB/T 18830-2002 not only sets out requirements for test methods, but also stipulates the evaluation and labeling of fabrics’ UV protection properties.

The standard requires testing��Homogeneous samples require 4 pieces, and non-homogeneous samples require 2 pieces based on color or structure. According to the tested spectral transmittance, calculate the uV-A and uV-B average transmittance and average UPF value respectively. Whether it is a homogeneous or heterogeneous material, the lower uPF value in the tested sample is used as the uPF value of the sample. Only when the tested textile meets the following conditions can it be labeled as an anti-UV product.

UPF value >30

Transmittance (UV-A)Av <5%

When the UPF value is greater than 50, it is marked as 50+. This standard applies to any fabric, but requires a note that “long-term use and use in a stretched or wet state will reduce the UV protection performance.”

5International UV Resistance Testing Association Standard

The “International Testing Association for Applied UV Protection” headquartered in Switzerland developed the standard “uV Standard 801” in response to the shortcomings of the AS/NZS 4399:1996 standard. The testing method of UPF value in this standard is the same as that of standard AS/NZS 4399, but adds sample processing processes such as friction treatment, washing (washing and dry cleaning), stretching and wet state, simulating the common occurrence of product during normal use. some circumstances or requirements. After corresponding testing and certification of the product, a certificate valid for no more than one year can be issued.

Test samples can be divided into two categories. The first category is clothing and fabrics, which require tensile and wet tensile UPF value tests on the samples in three states: untreated, after rubbing, and after washing (washing or dry cleaning). Usually 6 to 8 samples are needed. The second category is sunshade textiles (such as awnings, parasols and curtains, etc.). The samples need to be tested for UPF values in both untreated and sun-treated states, stretching and wet stretching. Generally, 4 samples are required. UV protection performance testing and evaluation standards are based on AS/NZS 4399. The UPF value labels available after testing are: 2, 5, 10, 15, 20, 30, 40, 60 and 80. Compared with the AS/NZS 4399 standard, the UPF value measured using UV Standard 801 is generally significantly lower. This is because the test conditions of the former sample are untreated, dry and unstretched.

6 Comparison of various standards

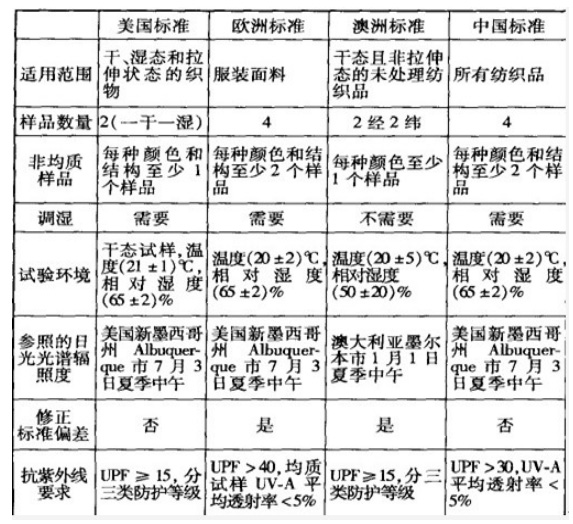

The standard indicators for evaluating the UV protection performance of textiles in various countries are mainly based on the UPF value, with appropriate consideration of the average transmittance of uV-A or uV-B. The European, American and Chinese standards refer to the solar spectrum irradiance of the United States, and the Australian and uV Standard 801 standards refer to the solar spectrum irradiance of Australia. The United States and Europe have separate standards for testing (sample pretreatment) and grading labels, while China and Australia have combined testing and grading labels into one standard. UV Standard 801 requires product testing and certification. In the ultraviolet protection performance test standard system, the American standard strengthens the pretreatment of fabric samples (simulating actual application for two years, the samples are washed, sun-dried and chlorinated pool water treated 40 times). Based on the Australian standard, uV Standard 801 adds pretreatment content (friction, washing, dry and wet stretching) to simulate practical applications. European and Chinese standards do not provide for sample pretreatment and focus on testing and grading labels. Therefore, they are slightly lacking in considering the actual application performance of the product.

Regarding the regulations for textiles with anti-UV properties, the American and Australian standards are UPF value ≥ 15, the European standard UPF value > 40 (UVA transmittance 30 (UVA transmittance < 5%), uV Standard 801 does not require it. Although the American and Australian standards both set the minimum UPF value of UV protection products at 15, the test samples are very different depending on whether they have been pre-treated, so the two are not comparable. Countries have significantly different criteria for judging UV-resistant textiles, and the testing methods are also different (see Table 2).

Table 2 Differences between UV protection test method standards in various countries

7 European and American customers’ requirements for UV protection products

European and American buyers have different requirements for UV-resistant textile products (such as beachwear, swimwear, sunshade textiles, etc.), so the standards adopted are also different. European and American customers’ purchasing requirements for UV-resistant textiles are based on the use of the final product, rather than on fabric type and finishing process. For example, American customers generally require corresponding pretreatment of textile products. After testing according to the AATCC 183 standard, the UV protection ability of the product is evaluated according to the ASTM D 6603 standard. The required product UV protection level and different requirements are determined according to the product use. UPF value. European customers use the EN 13758.2 standard to judge the UV protection performance of products, requiring the UPF value of UV-resistant products to be above 4O. However, a few European customers also require the BS 7914 standard.

Disclaimer:

Disclaimer: Some of the texts, pictures, audios, and videos of some articles published on this site are from the Internet and do not represent the views of this site. The copyrights belong to the original authors. If you find that the information reproduced on this website infringes upon your rights, please contact us and we will change or delete it as soon as possible.

AA