Progress in polyurethane waterproof and breathable coated fabrics

Progress in polyurethane waterproof and breathable coated fabrics

New textiles provide people with various excellent wearing functions, and waterproof and breathable fabrics are one of them. Waterproof and breathable fabrics are also called waterproof and breathable fabrics, and are also called “breathable fabrics” abroad. Consumers can count on the outerwear they wear to not only protect against rain and wind, but also be sweat-wicking, breathable, and comfortable to wear. This type of fabric is fundamentally different from the traditional “raincoat”. In fact, some varieties have begun to be favored by the fashion industry [5]. Their main feature is that they can quickly absorb sweat and sweat vapor formed by the human body. It is evaporated and discharged to avoid condensation in the clothes and keep the wearer dry and warm. Some people abroad have done research to obtain the approximate amount of sweat produced by people during exercise. When the breathability of clothing is lower than the amount of sweat produced by the human body, people will There is a feeling of stuffiness. Therefore, the breathability is an important indicator of the comfort of fabrics, especially sportswear.

Waterproof and breathable fabrics were first developed and used in the production of military uniforms and protective clothing. Now they are widely used in the manufacturing of sportswear, travel bags, tents, etc. The demand for this type of fabric in the international market is increasing year by year. In 1996, the output reached 67 million square meters [1]. Domestic products of this type are also under development.

1.1 High-density fabric

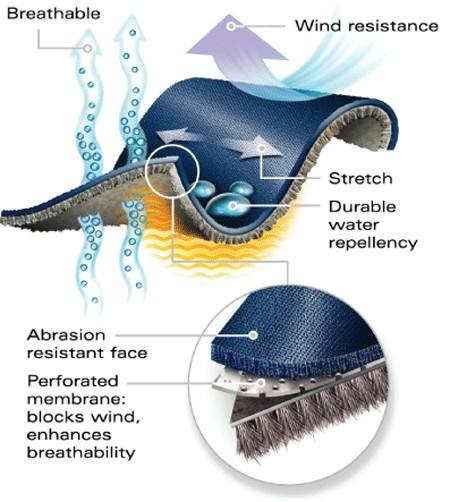

Ultra-fine fibers (fineness less than 1 dtex) are used to weave tightly, so that the gaps between the yarns are so small that water droplets cannot pass through. Some yarns expand when exposed to water, and the gaps will become even smaller. However, for water vapor molecules with a diameter of only four ten thousandths of a micron, the channel is wide enough to achieve the purpose of waterproofing and breathability.

1.2 Film lamination

This process is to laminate or bond a waterproof and breathable film, usually a microporous thin film, to various fabrics using a special adhesive to achieve waterproof and breathable effects [3]. Polytetrafluoroethylene microporous film composite fabric belongs to this category, and the author has also successfully researched and developed it.

1.3 Fabric coating

The processed fabric is coated using a direct or transfer coating process, and the coating closes the pores on the surface of the fabric to obtain waterproofness. Its air permeability is obtained through the large number of micropores or hydrophilic “molecular ladder channels” formed inside the coating during the forming process [2].

All the above methods have been applied. However, the processing costs are high and the performance needs to be continuously improved. In the late 1980s, research on coatings or films made of polyurethane materials (PU) was extremely active, and new processes and new varieties were constantly introduced, attracting widespread attention from various countries. Using polyurethane waterproof and breathable material, in addition to achieving satisfactory waterproof and breathable properties, its excellent elasticity, cold resistance and smooth feel, especially the relatively low processing cost, are favored by consumers and manufacturers, and have broad development prospects. It has high technological content and added value, and has more than a dozen foreign brands. Although domestic research is still in its infancy, it has great potential for development.

2Polyurethane with waterproof and breathable functions

According to the different mechanisms for obtaining breathability, polyurethane-coated fabrics or film-laminated fabrics can be divided into the following categories.

2.1 Microporous polyurethane

Its waterproof and breathable mechanism relies on the formation of a large number of micropores during film formation. These pores are less than 2?m, which can prevent water droplets (average diameter 100?m), but allow water vapor molecules (average diameter 0.0004?m) to pass [5], thereby achieving waterproof and breathable properties. There are three methods of film formation:

2.1.1 Wet coagulation method

It was successfully developed by the American DuPont Company[6], using water condensation to form a microporous polyurethane membrane. The more popular approach is to combine polyoxybutylene glycol (PBA)/4,4-diphenylmethane diisocyanate (MDI)/1,4-butanediol, or PBA/4,4-dicyclohexanediol. Isocyanate (H12MDI)/1,4-BD, molar ratio 1:3:2, is used to make an organic solution of polyurethane resin, such as dimethylformamide (DMF) solution. The forming process is: coat this solution on the fabric and immerse it in water in a water bath. Water and dimethylformamide are well miscible, but water is not a solvent for PU. Through two-way diffusion, water is continuously extracted from the resin solution. The solvent dimethylformamide enters the water phase, and at the same time, water enters the PU coating film, causing the polyurethane to gradually change from a dissolved state to a gel state, and then the polyurethane solid precipitates to form a film. During the formation of the film, due to the dehydration and shrinkage of the solidified phase, a large number of interpenetrating finger-like or honeycomb porous structures are formed in the coating film. The pore diameter is between 0.5?m and 2?m, and the surface pore diameter is 0.5?m. left and right[8]. The processing cost of this process is less than half that of Gore-Tex, the moisture permeability can reach about 4000g/m2·24h, and the hydrostatic pressure resistance is about 200cm. This type of product has been adopted by well-known sportswear manufacturers such as Nike, Puma, Adidas, Umbro, etc. [8]. Representative brands include “Entrant” from Japan’s Toray Company, “Ultrex” from Burlington Company in the United States, and “Tarka” from NylaPenn Company in the United Kingdom [9].

Similar to this type of method is the salt coagulation method, which is to apply PU emulsion and add salt to break the emulsion and deposit it, which can also form a microporous film. Examples of companies that use this process include Permutex from Stahi (ICI)/NL in the UK, and Porelle film produced by Porvail/GB in the UK [10].

2.1.2 Water-in-oil W/O emulsion method (also called dry method)

The polyurethane resinThe newly developed EntrantGll is a composite of two polyurethane materials. The inner polyurethane contains micropores and ultramicropores (<0.5?m=, which uses its "wicking" effect to suck moisture from the skin and spread it to the outer layer. , and then discharged into the air to improve perspiration.

3.2.3 Polyurethane coating additives[16]

Use the method of adding other substances to the polyurethane coating agent. It can not only improve the breathability of PU film, but also give the fabric insecticidal and sterilizing effects, as well as an excellent hand feel. Chitin is an extract of the scales of shellfish, aquatic organisms and animals. Its chemical structure is as follows:

Chitin is similar to cellulose macromolecules, but the amide group at the 2-position makes it insoluble in most organic bath agents and antimicrobial. Chitin has high hygroscopicity and hygroscopicity, and has certain antimicrobial properties. After a certain amount of chitin is mixed into the coating agent, it will keep sweat and body fluids clean and have certain medical and health care effects. Such as Japan Asahikaseid’s “Biochiton”. In addition, studies on adding wool shavings, silk shavings, scale powder, cellulose powder, etc. to improve the moisture permeability of fabrics have been reported [14]. The temperature of these powders is high when they are added. When cooled and solidified, the volume shrinks and the phase separation occurs. Micro gaps are formed inside the coating film and around the powder chips, which increases the moisture permeability [1].

3.3 Research and development of pollution-free polyurethane

It has always been the wish of scientific and technological workers to develop a PU coating agent that is completely water-dispersed and has no solvent pollution during the synthesis and application process. Current processing techniques, whether wet or dry, use a certain amount of volatile organic solvents during the processing, which causes environmental pollution problems. If PU is made into a water-soluble coating agent and cross-linked to form a film during the drying process, it will not only greatly reduce production costs, but also overcome environmental pollution problems, so research in this area is also very active. Ureatech, newly launched by Polytech in the United States, is said to be focusing on this aspect and is known as a “high-tech product for the new century”. There are also domestic research reports in this area [17].

3.4 Metal and ceramic coatings

Without affecting the original waterproof and moisture permeability, metal powder is mixed into the resin to form a metal layer that reflects the radiant heat of the human body and reduces heat loss. This kind of coating is suitable for use as sportswear bags for mountaineers in winter or alpine areas, such as Entrantthermo from Toray of Japan and Lyonthermo from Asahi Kasei of Japan [15]. When PU is mixed with ceramic powder with high far-infrared emissivity, this coating can absorb the energy of sunlight or human body heat, radiate far-infrared rays to the human body, improve the warmth retention performance of the fabric, and promote the microcirculation of the human body. [19]. Such as Japan’s Toray Corporation’s Megaclon, Japan’s Asahi Kasei’s VeraV, Japan’s Masonic. Some ceramics also have the function of absorbing odors such as ammonia and hydrogen sulfide. After being mixed into the coating, they become deodorizing waterproof and breathable fabrics, such as Permilan and Deodrant from Japan’s Unitika Company.

4Conclusion

Waterproof, breathable and special functional coated fabrics are high-tech, high value-added products. Various processing technologies constitute a family of waterproof, breathable and special functional coated fabrics, while the polyurethane series is a colorful branch with development potential. Western countries and developed countries such as Japan have invested a lot of manpower and financial resources in competing for development and research, but domestic research is still relatively small. In addition, the United States and Japan also regard such products as high-tech products for the new century. As for the development and research of competitive products in the textile market, our country’s scientific and technological workers in this field should seize the opportunity and catch up. pt1Hov

Disclaimer:

Disclaimer: Some of the texts, pictures, audios, and videos of some articles published on this site are from the Internet and do not represent the views of this site. The copyrights belong to the original authors. If you find that the information reproduced on this website infringes upon your rights, please contact us and we will change or delete it as soon as possible.

AA