Waterproof fabric made of silicon nanomaterials

Weft yarns with a true twist of 700 twist/m have greater fabric stiffness, higher tensile properties, and average formability. It can be seen that weft yarns with a smaller true twist have better fabric formability.

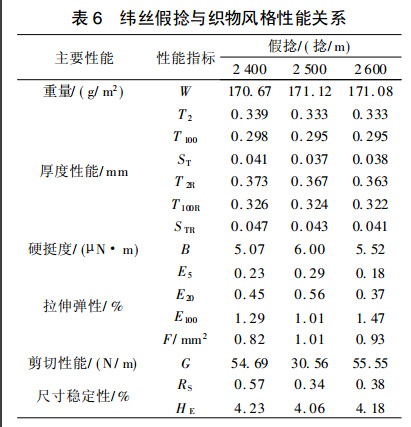

2.4 Relationship between weft false twist and fabric style and performance

When the process conditions are: upper overfeeding 100%, lower overfeeding -25%, true twist 700T/m, and the false twist values are 2400, 2500, and 2600 twist/m, the style index values are shown in Table 6.

Changing the size of the false twist during weft processing has little effect on the thickness properties of the fabric, but the relaxed thickness of the fabric is inversely proportional to the size of the weft false twist. It shows that the fabric with higher false twist has a more stable thickness after finishing, and the finished garment is not easy to deform. The false twist of the weft is 2500 twist/m, the fabric stiffness B is large, the tensile performance and formability are also high, the shear stiffness is low, the fabric is crisp and elastic, and the garment is easy to create a plump shape, but 100cN/cm

2. The weft elongation (E100) of the lower fabric is small. Under the action of large tensile force, the fabric has small extensibility, which limits its overfeeding sewing and wearing comfort, but its dimensional stability is good. When the weft false twist is 2400 twist/m and 2600 twist/m, the fabric is soft and comfortable, but the relaxation shrinkage rate and wet expansion rate are large. The garment is sensitive to heat and moisture during garment processing and wearing, and the garment is easy to deform. From the above, it can be seen that a moderate false twist of 2500 twist/m is more beneficial to the fabric style.

Conclusion

a) Changes in overfeeding have a significant impact on the tensile elastic properties of fabrics. In the range of 80% to 100%, under the conditions of small elongation of E5 and E20, the tensile capacity of the fabric increases first and then decreases; under the condition of large elongation of E100, the tensile capacity of the fabric gradually increases.

b) The change of lower overfeeding has a significant impact on the tensile elastic properties of the fabric. The lower overfeeding is in the range of -25%~-30%. In the case of small elongation of E5 and E20, the tensile capacity of the fabric decreases first. It increases after a small value; under the condition of large elongation of E100, the tensile ability of the fabric gradually decreases.

c) With weft yarns of moderate true twist size, the fabric is stiffer and has good formability.

d) When the weft false twist is larger, the thickness of the fabric will change less during finishing. Choosing a moderate amount of false twist is beneficial to obtaining fabrics that are crisp, elastic and with good formability. Z4X1yOFzTx

Disclaimer:

Disclaimer: Some of the texts, pictures, audios, and videos of some articles published on this site are from the Internet and do not represent the views of this site. The copyrights belong to the original authors. If you find that the information reproduced on this website infringes upon your rights, please contact us and we will change or delete it as soon as possible.

AA