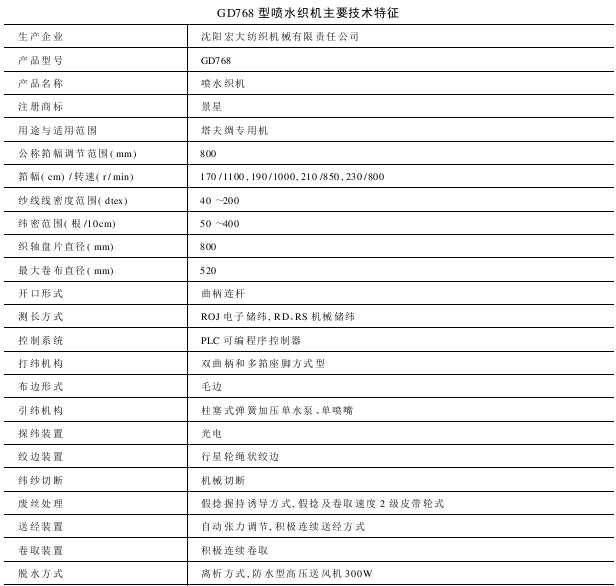

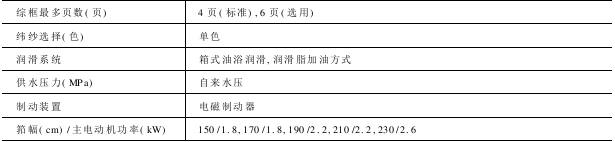

GD768 water jet loom

The GD768 water-jet loom is a new generation of ultra-high-speed jet loom developed by Shenyang Hongda Fabric Machinery Co., Ltd. after introducing the Japanese Nissan water-jet loom design and manufacturing technology. It produces the GD767 model and absorbs the advanced technology of foreign looms. Water loom.

Suitable weaving varieties Suitable for weaving light and thin fabrics.

Main features: High speed, high reliability and low energy consumption, which can meet the requirements of users to reduce costs and improve production efficiency. Compared with previous looms, the let-off distance is significantly shortened to reduce the friction load between let-off warp threads and reduce the floor space.

Use box-type wall panels to enhance the strength of the base frame, and use small-area pump plugs, nozzles, and one-way valves to achieve the weft insertion rate with a small amount of water. Therefore, the problem of warp defects in nylon taffeta caused by high-speed operation is greatly reduced, thereby ensuring high-grade weaving. Fully adopting new RD length measurement and high-speed components, the body is lightweight, high-rigidity and high-strength, thereby achieving high-speed operation and greatly reducing maintenance and repair costs.

The weft insertion device adopts a new nozzle to improve the clustering of the spray water and the weft insertion ability. Changing the installation direction of the water pump can shorten the distance from the water pump to the nozzle and reduce pressure loss.

Shedding device: The shedding connecting rod is lengthened to make the tension of the upper warp yarn and the lower warp yarn more uniform during shedding. High-quality fabrics are obtained even at high speeds. By adjusting the opening crank, you can easily select the appropriate opening amount. Adopt reliable centralized refueling device. Adapt to high speed and easy to operate.

Warp let-off device uses a weight to adjust the warp tension change, making the warp tension change more stable. The adjustment range from high tension to low tension is wide and easy to adjust. The tension changes smoothly from the full shaft to the empty shaft. No other compensation devices are required.

The winding device adopts an automatic tension adjustment mechanism so that the fabric can be wound with appropriate tension. The wrinkle prevention device adopts a rod structure.

Length measuring device The single-jet loom adopts the new RD length measuring device, the weft storage drum operates at high speed and the air flow storage method is used. Weft yarn holding and storage reduces weft yarn tension. This device has a simple weft threading process and a direct route to the nozzle, which reduces the weft load. Thereby reducing weft yarn tension and damage rate. Using a belt-driven turbine fan, optimal air volume and wind pressure can be set to achieve low air volume and high-speed operation.

The beat-up device adopts a short-handled double-sided four-link lightweight beat-up shaft to reduce mechanical vibration.

Control system Built-in PLC control system, higher control accuracy.

AAASDFWFWFWE

Disclaimer:

Disclaimer: Some of the texts, pictures, audios, and videos of some articles published on this site are from the Internet and do not represent the views of this site. The copyrights belong to the original authors. If you find that the information reproduced on this website infringes upon your rights, please contact us and we will change or delete it as soon as possible.

AA