Friends who often exercise outdoors must know that outdoor clothing is generally made of waterproof and breathable fabrics. The fabric of the jacket serves as the outer protective layer, the middle waterproof and breathable layer and the lining to meet the waterproof and other characteristics of the jacket.

Waterproof and breathable, which sounds like a pair of contradictions in itself. Since it is waterproof, it is sealed. We We all know that water is permeable, so how can it be breathable? In fact, this is related to the characteristics of water. As we all know, the surface of water has tension. In life, we can find that when we pour water, the water can often be a little higher than the mouth of the cup without flowing out. This is the surface tension of water. As a result, this phenomenon is mainly because water molecules only have a relatively large molecular attraction, making each water molecule as closely connected as possible without being separated. Water vapor is also a water molecule, but at this time, the distance between each water molecule are completely independent and therefore not so closely linked. Taking advantage of this characteristic, the laboratory found through tests that if the hole is small enough, it can only allow water in the vapor state to pass through but not liquid water. Taking advantage of this characteristic, waterproof and breathable materials were invented

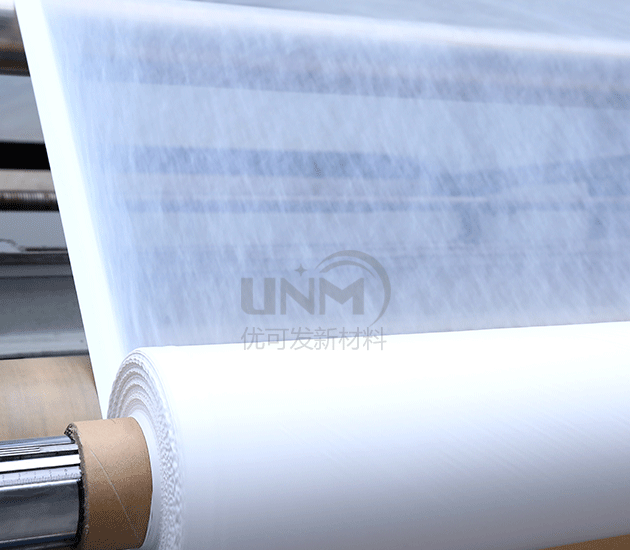

Clothing ptfe composite fabricUsing the pore-forming characteristics of polytetrafluoroethylene plastic resin, Microporous film made by biaxial stretching method. The surface of the membrane can reach more than one billion micropores per square centimeter. The diameter of each micropore (0.1μm-0.5μm) is hundreds of times smaller than the diameter of water molecules (20μm-100μm) and smaller than the diameter of water vapor molecules (0.0003μm-0.0004 μm) is tens of thousands times larger, allowing water vapor to pass through, but water droplets cannot pass through. This microporous structure can be used to achieve excellent waterproof and moisture-permeable functions; in addition, because the pores are extremely small and are arranged in irregular longitudinal bends, wind cannot Through it, it has the characteristics of wind resistance and warmth retention. After compounding with other fabrics, Clothing ptfe composite fabric is widely used in military clothing, clothing, casual clothing, special protective clothing such as fire protection, anti-virus, and water immersion operations, outdoor sports clothing, shoes, hats, gloves, etc. Accessories and sleeping bags, tents, rain gear and other materials.

The six popular composite processes in the world are hot melt powder coating composite process, hot melt slurry composite composite process, hot melt powder composite process, process, thermal Melting double-point composite process, polyurethane spray composite process, and polyamine roller coating composite process are a new type of fabric developed in the market. Simply put, it is a fabric that combines two fabrics. The more common compound used in the past was a combination of suede and wool, which can now be mixed with any fabric.

It is a manufacturer that produces clothing ptfe composite fabric. The material can be used as protective clothing, jackets, and mountaineering clothing. Its main It is characterized by being waterproof and breathable. When used as a clothing material, it has good comfort when worn by the human body. Its waterproof and breathable function is mainly a layer of ptfe film compounded with the fabric. Clothing ptfe composite fabric is prepared by bidirectional stretching using a special process. Its surface has a fibrous microporous structure. These micropores The pores are evenly distributed, with small pore diameter and high porosity. Interested parties can enter the store for consultation and purchase!

</p