The exhaust gases emitted by various industrial furnaces and kilns in metallurgy, machinery, chemical industry, electric power and other industries are not only high in temperature, but also contain a large amount of dust and harmful gases, which cause environmental pollution. One of the main factors. In order to solve this problem, it is necessary to use filter materials. What is introduced here is Teflon high temperature membrane. Let’s take a look at this material.

Dust removal bags are often widely used in industrial dust removal. High-temperature dust bag can be called the heart of bag dust collector, generally called dust bag or dust bag. Dust bag is a key part of the operation process of bag dust collector. The fabric and design of the dust bag should strive for efficient filtration, easy dust removal and withstand long-term use. Generally, cylindrical dust bags are hung vertically in the dust collector. High temperature dust removal bags are widely used in steel plants, cement plants, power plants, non-ferrous metal smelting, carbon black plants, chemical plants, waste incinerators, asphalt concrete mixing stations, food processing plants, and wood processing plants. The temperature-resistant dust bag adopts different surface chemical treatments and finishing technologies such as PTFE impregnation, which is easy to remove dust, hydrophobic, and oil-proof; the temperature-resistant dust bag is suitable for different temperature ranges such as 150-200°C, 200-250°C, and 250-300°C.

There are many filter materials for dust removal bags. Here, the Teflon high-temperature membrane manufacturer briefly introduces two types to you. One is to coat polytetrafluoroethylene fiber on a base cloth made of other filter materials (polyphenylene sulfide fiber, P84 polyimide fiber, glass fiber, etc.); the other is to coat and base cloth both made of Made of polytetrafluoroethylene fibers and processed into needle felt. PTFE fiber filter bags have better performance. Although PTFE fiber has excellent properties, it is more expensive.

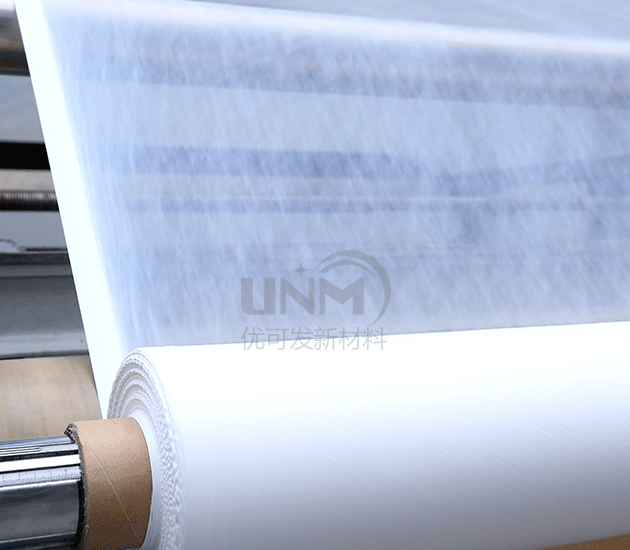

The Teflon high temperature membrane produced by the manufacturer is the core filter material of the dust bag. According to the usage requirements, the pore size can be between 0.1-1um. The thickness can be between 10-100um, the porosity can reach 50%-90%, and there are hundreds of millions of micropores per square centimeter. Since the pore size of the microporous membrane is much larger than that of water vapor molecules, and the operating temperature can reach -150℃-250℃, Teflon high temperature membrane has excellent corrosion resistance, aging resistance and temperature resistance. This membrane is a microporous organic membrane currently on the market that has high porosity, corrosion resistance, aging resistance, temperature resistance, hydrophobicity, good moisture permeability and air permeability, and is widely used. Interested parties can enter the store for consultation.

</p