In chemical industry, petroleum, metallurgy, electric power and other industries, the high-temperature dust-containing gas that often remains after the action of processes or working fluids is passive flue gas. Key research areas of waste heat resources. Due to different processes requiring energy recovery or meeting environmental protection emission standards, these high-temperature dust-containing gases need to be dusted. Because of its excellent performance, Teflon’s Teflon high-temperature membrane can be used in industrial dust removal.

Because of the current filtration engineering application of high-temperature flue gas, that is to say, the long-term operation of the filter bag generally requires the cooling of high-temperature flue gas through After the measures are taken, the temperature should be lower than about 200℃~250℃.

High-temperature filtration and dust removal technology is one of the most promising technologies in particle capture in recent years. Filter media is the core of high-temperature filtration technology and can be called the “heart”. The quality of the filter media directly affects the filtering effect and filter life. The filter unit can be classified accordingly according to whether the filter material is composed of fibers or particles, that is, filter fiber materials and particle layer filter materials.

Due to the characteristics of high working temperature and strong gas corrosiveness, there are high requirements for filter materials for high-temperature gas dust removal. Filter materials need to meet requirements in terms of filtration characteristics, service life, price, etc. At present, the excellent temperature resistance and corrosion resistance of Teflon high temperature membrane makes it an ideal filter material in various fields of high temperature flue gas from waste incineration. The fiber has low friction, flame retardancy and good insulation properties. Can withstand the oxidative corrosion of various strong oxides. FTFE fiber is not prone to hydrolysis reactions. It has high collection efficiency and is not easy to accumulate dust. Even when the temperature is high and the dust concentration is high. Only a small amount of dust adheres to the surface. The dust cleaning performance is better.

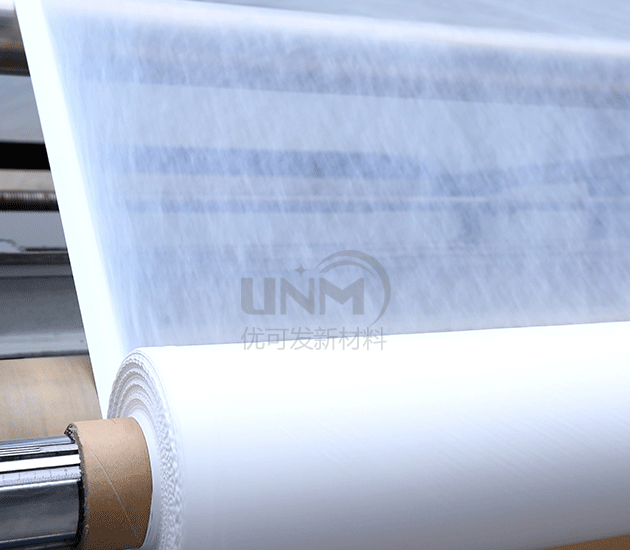

Teflon high-temperature membraneThe product has a microporous structure with staggered fibers. It is processed through a two-way stretching process and is heat-set at high temperature. The microporous structure is very stable and can intercept dust particles very well. Moreover, the pore size of the material is small and the distribution is concentrated, achieving surface filtration to achieve a dust removal efficiency of 99.9%~99.999%. For some small particles with a diameter of 0.1um-0.3um, it can well prevent fine dust from entering the filter material. It can operate at a continuous operating temperature of 240°C and an instantaneous temperature of 260°C. Teflon high-temperature membrane can be restored to performance through water washing or pulse backflushing, and has a long service life. Interested parties are welcome to enter the store and consult us.

</p