There are many specifications of Oxford cloth, such as 210D, 300D, 420D, 600D, 1000D, 1680D, etc., but the most beautiful printed one is 210D Oxford cloth, because its yarn count is finer than others. Printing methods are divided into three categories: screen printing, transfer printing, and inkjet printing. Today, let’s first understand what screen printing is.

Current Application The most common is screen printing. The screen is the main printing tool. There are hollow meshes in the patterned areas, and the meshes in the non-patterned areas are coated. During printing, the color paste is scraped through the mesh and transferred to the Oxford cloth. According to the shape of the screen, it can be divided into flat screen printing and rotary screen printing.

The screen of flat screen printing is flat, and there are three types of printing machines: manual flat screen printing machine (ie, platen printing machine), semi-automatic flat screen printing machine and fully automatic flat screen printing machine.

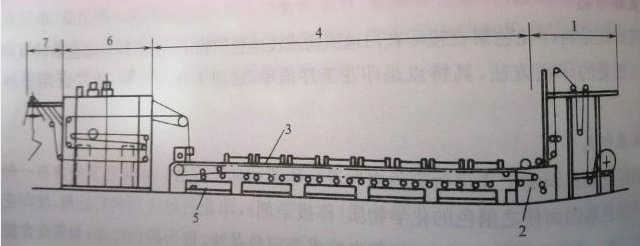

Fully automatic flat screen The printing machine is as shown in the figure. When printing, the sizing device applies a layer of cloth paste on the rubber guide belt, and then automatically sticks the cloth on the guide belt. When the screen falls on the table, the rubber or magnetic rod The scraper scrapes the pulp. After scraping, the screen rises and the Oxford cloth moves forward with the rubber conductor. These chain processes are controlled by the automatic printing device. Each screen is printed with a color. After the Oxford cloth is printed, it is dried in a drying device and then post-processed. The rubber conductor is transferred to the bottom of the platen and washed by a water washing device to remove the cloth paste and printing color paste. .

To learn more about printed Oxford cloth, please consult customer service or call the hotline: 400-8380917.

</p