PU coating is divided into coating forms. Simply put, it can be divided into water-based and solvent-based polyurethane. Solvent-based film-forming properties are good, strong adhesion to fabrics, high water pressure resistance, and more suitable for waterproof and moisture-permeable coatings. However, the solvent type is toxic and flammable, and is not environmentally friendly. The water-based type is safe, non-toxic, and environmentally friendly, but has poorer adhesion to fabrics and weaker water pressure resistance than the solvent type.

Coating processing techniques include dry method, wet method, hot melt method, transfer method, adhesive method and other methods. Among them, the dry method is the most used. The dry method is to apply the coating slurry with The cloth is evenly coated on the base fabric, and the solvent or water is heated to evaporate, and the coating forms a thin film on the surface of the fabric. The PU thin coating is a high-end product in dry direct coating, mainly used for clothing fabrics.

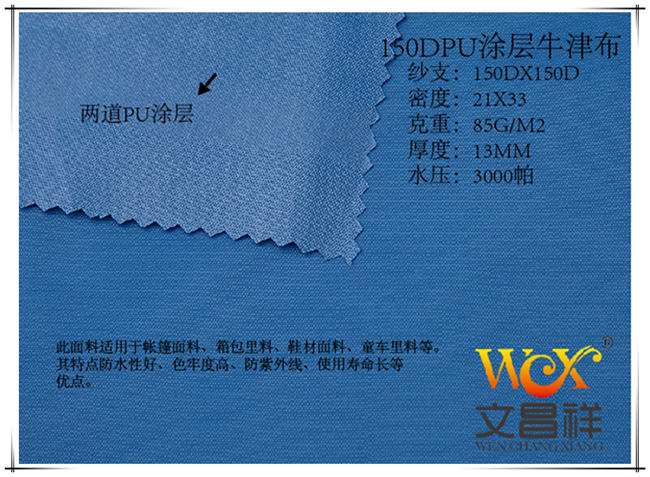

The PU coating can have waterproof function by adding a waterproof coating later. It is widely used in sportswear, down jackets, rain-proof parkas, jackets, tents, shoes and socks, curtains, bags and ski shirts with advanced waterproof and moisture-permeable functions, mountaineering clothes, windbreakers, etc. It can also be used in national defense, navigation, fishing, offshore oil wells, transportation and other fields. Waterproof coating series fabrics have multiple functions such as windproof, waterproof, and moisture permeability.

Textile’s main products are Oxford cloth: waterproof Oxford cloth, flame-retardant Oxford cloth, coated Oxford cloth, fluorescent Oxford cloth, etc. If you are interested in or have questions about the products of Suzhou Textile Co., Ltd., please contact the online customer service on the web page, or leave a message for dedicated service. Meet all your needs.

</p