Flame retardant fabric, polyester flame retardant fabric, using the latest ATP flame retardant finish, has the characteristics of water resistance, excellent flame retardant effect, good hand feel, non-toxic and safe.

Flame-retardant fabrics are partly made of innate flame-retardant fibers through spinning, weaving, and dyeing. The fabric has the characteristics of flame retardant, wear-resistant, temperature-resistant, washable, acid and alkali resistant, waterproof, anti-static, and high strength.

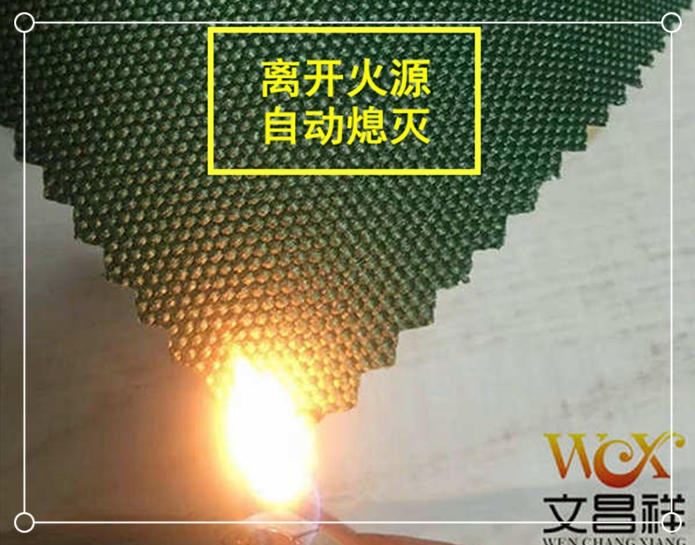

Flame-retardant cloth refers to a cloth that can automatically extinguish within 2 seconds of leaving the open flame even if it is ignited by an open flame. According to the order of adding flame retardant materials, it is divided into two types: fiber intrinsic fiber flame retardant cloth and finishing flame retardant cloth.

Two main ways to achieve flame retardant functionality in textiles:

First, the flame retardant with flame retardant function is polymerized through polymer polymerization, blending, copolymerization, composite spinning, and splicing. Technical modifications, etc. are added to the fiber to make the fiber flame retardant.

Second, the flame retardant is coated on the surface of the fabric or penetrated into the fabric using post-finishing methods. These two methods have different steps in giving fabrics flame retardancy, and the effects they produce are also different.

Independently research and develop flame-retardant fabrics. According to different requirements of customers, the following specifications are available: 210D, 300D, 420D, 600D, 900D, 1200D, 1680D Oxford cloth, etc., which have temporary flame-retardant effect, semi- Durable flame retardant effect and durable flame retardant effect can also be provided with waterproof, flame retardant, PVC/PU coating, silver coating, composite and other treatments according to customer needs. You can contact the online customer service on the web page or leave a message. , to meet all your requirements with dedicated service.

</p