Pneumatic conveying Pneumatic conveying system

Pneumatic conveying systems can be divided into three categories: suction type, pressure feeding type and mixed type according to their device form and working characteristics.

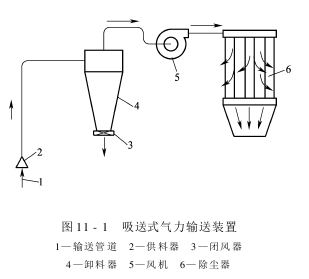

(1) Suction type

The suction type pneumatic conveying device uses a ventilator to suck air and materials into the conveying pipe and transport them to the discharge location. It is often used for material transportation inside the workshop, as shown in Figure 11-1.

Material transportation It is completed on the suction section side of the fan. The characteristics of this conveying method are: the conveying device works under negative pressure, which can not only convey materials, but also collect dust. Materials and dust will not escape and fly, ensuring the hygiene inside the workshop; it is suitable for materials to be transported from multiple locations. Concentrated transportation to one place; suitable for conveying materials with a wide accumulation area or low or deep storage; the feeder has a simple structure; the unloader has high sealing requirements, and the conveying volume and conveying distance are subject to certain restrictions. The suction-type pneumatic conveying system is used in the goods yard of the cotton finishing factory for cotton suction, cotton distribution, cotton collection, lint collection, scrap recycling and air distribution.

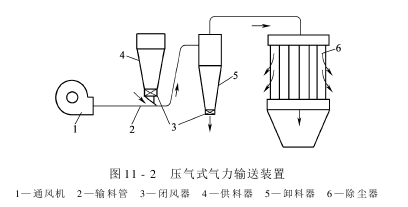

(2) Pressure-feeding type

The pressure-feeding pneumatic conveying device uses the air flow pressed out by the ventilator to mix the material with the material when passing through the conveying pipe, as shown in Figure 11-2. The material conveying process is completed on the side of the compressor section of the fan.

This kind The characteristics of the conveying method are: the feeding pipe is bifurcated and equipped with a reversing valve, which can change the conveying route or convey to several places at the same time; it is suitable for large flow and long-distance conveying; the entire device is under positive pressure and the material is easily discharged. The material outlet is discharged, so the structure of the unloader is simple, but it is easy to cause dust to escape; the structure of the feeder is relatively complex.

Cotton finishing plants rarely use pressure-feed conveying, which is generally used to convey cotton after stripping.

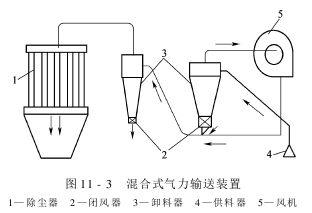

(3) Hybrid type

The hybrid pneumatic conveying device transports materials in both the suction pipe section and the pressure pipe section of the fan, that is, it is a combination of suction type and pressure feeding type, as shown in Figure 11-3 shown.

Hybrid The pneumatic conveying device has the characteristics of both suction and pressure feeding. This conveying method is used for circulating lint during cotton finishing.

The pneumatic conveying system of a cotton finishing plant generally consists of a feeder, a conveyor pipe, an unloader, an air closer, a dust collector, a ventilator and other equipment.

AAASDFERGTRHR