How much do you know about fiberglass cloth?

What is fiberglass cloth made of?

Glass fiber cloth is made of glass balls or waste glass as raw materials through high-temperature melting, drawing, winding, weaving and other processes. The diameter of its single filament ranges from a few microns to more than 20 microns, which is equivalent to a 1/20-1/5 of the hair strands, each fiber bundle is composed of hundreds or even thousands of single filaments.

What are the characteristics of fiberglass cloth?

1. Used between low temperature -196℃ and high temperature 300℃, with weather resistance.

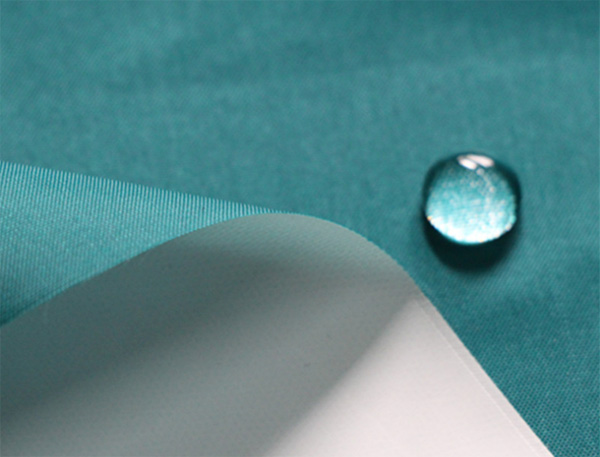

2. Non-adhesive, not easy to adhere to any substance.

3. Resistant to chemical corrosion, able to withstand corrosion from strong acids, strong alkali, aqua regia and various organic solvents.

4. The friction coefficient is low, making it the best choice for oil-free self-lubrication.

5. The light transmittance reaches 6~13%.

6. It has high insulation performance, anti-ultraviolet and anti-static properties.

7. High strength. Has good mechanical properties.

8. Resistance to agents

What is the function of fiberglass cloth?

Someone asked what role fiberglass cloth plays? It’s like a house made of cement and steel bars. The fiberglass cloth acts like a steel bar, acting as a reinforcement for the FRP.

In what fields can fiberglass cloth be used?

Glass fiber cloth is mostly used in hand lay-up process. Glass fiber reinforced material grid cloth is mainly used in ship hulls, storage tanks, cooling towers, ships, vehicles, tanks, and building structural materials. Fiberglass cloth is mainly used in industry for: heat insulation, fire prevention, and flame retardant. The material absorbs a large amount of heat when burned by flames and prevents the flames from passing through and insulating air.

What are the classifications of fiberglass cloth?

1. According to ingredients: mainly medium-alkali, no-alkali, and high-alkali (which classify the components of alkali metal oxides in glass fibers). Of course, there are also classifications based on other ingredients, but there are too many varieties to cover them all. enumerate.

2. According to the manufacturing process: crucible drawing and kiln drawing. 3. According to type: plied yarn, direct yarn, jet yarn, etc. In addition, they are distinguished according to single fiber diameter, TEX number, twist, and sizing agent type. The classification of fiberglass cloth is the same as that of fiber yarn. In addition to the above, it also includes: weave, weight, width, etc.

What is the difference between fiberglass cloth and glass?

There is not much difference between the main materials of fiberglass cloth and glass, mainly due to different material requirements during production, so there are some differences in formulas. The silica content of flat glass is about 70-75%, and the silica content of glass fiber is generally less than 60%.

Glass is an inorganic material that has been melted at high temperatures (above 800 degrees, daily glass is generally melted at 1100 degrees). It does not undergo chemical changes below the softening point. Above the softening point temperature, it will only soften, melt or decompose, and will not burn.

Fiberglass cloth is made by drawing glass into extremely fine glass filaments. At this time, the glass filaments have good softness. Glass fiber is spun into yarn and then passed through a loom to weave fiberglass cloth. Because the glass filaments are extremely thin and the surface area per unit mass is extremely large, the temperature resistance is reduced. Just like using a candle to melt thin copper wire.

But glass doesn’t burn. The combustion we can see is actually the resin material coated on the surface of the fiberglass cloth, or the attached impurities in order to improve the performance of the fiberglass cloth. Products such as fire-resistant clothing, fire-resistant gloves, and fire-resistant blankets can be made from pure fiberglass cloth or after being coated with some high-temperature resistant coatings. However, if it comes into direct contact with the skin, the broken fibers will cause irritation to the skin and cause itching.

What is the difference between fiberglass cloth and fiberglass?

Fiberglass cloth is the material for making FRP products. FRP is actually a kind of composite plastic. It is made of glass fiber and resin, curing agent, accelerator and other materials through various processes and then solidified.

What should I do if I accidentally get fiberglass cloth on my clothes or body?

Generally, the diameter of conventional glass fiber monofilaments is above 9-13 microns. Glass fiber floats below 6 microns can directly enter the lung ducts and cause respiratory diseases, so special attention should be paid. Most fiberglass floats below 6 microns are now imported. Professional masks must be worn during production operations. If exposed frequently, it may be inhaled into the lungs and cause pneumoconiosis.

If you get fiberglass on your body, you may be allergic or itchy if you have bad skin, but it is generally not harmful. If you have bad skin, you may develop small bumps. That is an allergy. Just take some anti-allergy medicine. .