Why should textile fabrics be flame retardant? How to achieve flame retardancy?

Why should textile fabrics be flame retardant? How to achieve flame retardancy?

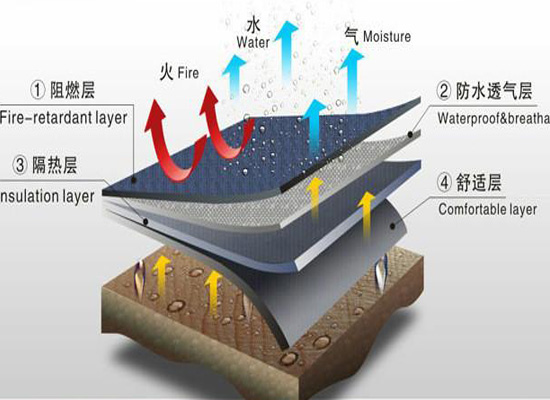

As we all know, textiles are flammable. Once a fire breaks out, textile fabrics will spread quickly and easily pose a threat to life and property. Flame-retardant fabrics are even more important for special occupational groups such as oil field workers and firefighters. They have Good defensive effect can protect human skin from fire burns to a certain extent to ensure the life safety of relevant staff. In order to minimize the risk factor, everything should be done before it happens. It is an important barrier to make the fabric flame-retardant, delay the spread of fire, and give people in distress enough time to evacuate or take measures to put out the fire.

The flame retardancy of textiles does not mean that textiles will not burn when exposed to a fire source after flame retardant finishing. It means that the fabric can reduce its flammability in flames, quickly slow down the spread, and will not cause large-area burning. That is, it can self-extinguish quickly within a short period of time after leaving the flame.

So, how is the flame retardancy of textiles achieved?

1. Use flame-retardant fibers to weave flame-retardant textiles

2. Use post-finishing methods to prepare flame-retardant textiles

The post-finished flame retardant fabric is treated with flame retardant by spraying, padding or coating. When encountering fire, the flame retardant will undergo physical and chemical reactions to achieve the flame retardant effect.

Fiber modified flame retardant mechanism

Fabrics can obtain unique functions through fiber modification, reducing flammability or improving flame retardancy, such as:

1) It can improve the melting performance of the fabric, causing the fiber material to soften, shrink, and melt before thermal cracking, turning into molten droplets and dripping, and the heat is taken away to make the flame self-extinguishing;

2) By introducing aromatic rings or aromatic heterocycles into fiber macromolecules, the density and cohesion between fiber molecular chains are increased, thereby improving the heat resistance of the fiber;

3) By modifying the fiber, for example, cross-linking and cyclizing macromolecular chains, forming complexes with metal ions, etc., the molecular structure of the fiber is changed, thermal cracking is inhibited, and the generation of flammable gases is reduced.

Catalytic dehydration to carbon flame retardant mechanism

During the heating process, the flame retardant promotes the dehydration, cyclization and cross-linking processes of the fiber by changing the thermal cracking of the fiber, thereby forming a carbon layer. The formation of the carbon layer can reduce the generation of flammable gases and can also cover and insulate fabrics. Most of the flame retardants that work with this flame retardant mechanism are phosphorus-containing flame retardants. It is generally believed that phosphates and organic phosphate compounds have a flame retardant effect because they undergo an esterification reaction with the hydroxyl groups in the fiber macromolecules, preventing the formation of L-glucose, further dehydrating the cellulose, and generating unsaturated double bonds. It speeds up the cross-linking reaction between cellulose molecules, increases the carbon residue generation rate of the fabric, and achieves the purpose of flame retardancy.

Vapor phase flame retardant mechanism

There are two main theories for the gas phase flame retardant mechanism, one is the gas dilution theory, and the other is the free radical theory. The gas dilution theory believes that the mechanism of flame retardancy is due to the thermal decomposition of flame retardants to produce non-combustible gases. These gases dilute the concentration of flammable gases, resulting in insufficient oxygen during the burning process of the fabric, and the diffusion of such gases causes It can dissipate heat and cool down, thus achieving the flame retardant effect; the free radical theory believes that the thermal cracking products of flame retardants can interrupt the combustion chain reaction, because the cracking products can capture a large amount of high-energy oxygen free radicals and hydrogen free radicals during the combustion process. base, thereby exerting a flame retardant effect. The main ones that work on the gas phase flame retardant mechanism are ammonium-containing flame retardants and halogen flame retardants. The former is a gas dilution mechanism, and the latter is a free radical theory.