[Popular Science Knowledge] Manufacturing, performance and application of meta-aramid fiber

[Popular Science Knowledge] Manufacturing, performance and application of meta-aramid

Excellent performance and wide application

Meta-aramid MPIA (poly-m-phenyleneisophthalamide) is an excellent flame-retardant and heat-resistant fiber. It also has satisfactory comprehensive physical properties, resistance to harsh environments and excellent processability. These properties enable meta-aramid products to play a unique role in many demanding protective situations. The fiber was first successfully developed by DuPont in the United States in the 1960s and introduced to the market under the trade name Nomex in 1967. There are two rigid benzene rings in the molecule, which greatly improves its heat resistance. Its main use is to make thermal protective clothing, filter materials and flame-retardant decorative cloths, which are used in military, fire-fighting and other fields.

Meta-aramid fiber is poly-m-phenylene isophthalamide fiber. It has long-term thermal stability and can be used for a long time at a high temperature of 200°C without aging. It has excellent dimensional stability. Meta-aramid is intrinsically flame retardant, with a limiting oxygen index value of >28%. It will not spontaneously ignite or melt in the air, nor will it produce droplets, and will self-extinguish upon leaving the flame. It has excellent electrical insulation, and the insulating paper made from it has a breakdown voltage of up to 20kV/mm; meta-aramid has excellent corrosion resistance and radiation resistance. In addition, meta-aramid also has low rigidity and high elongation, and can be processed by conventional textile machinery.

Continuous process research and exploration

The main process of manufacturing meta-aramid and insulating paper involves 43 processes and 128 units. The control of the production process is very strict. Otherwise, side reactions will occur due to unequal global/local equivalents and unequal diffusion control, resulting in The polymer has problems such as low relative molecular mass and wide relative molecular mass distribution. In order to stabilize production quality and achieve mass production, special twin-screw reaction equipment has been developed. This equipment integrates continuous polymerization, neutralization, stable slurry pH value, subsequent dissolution, deaeration, and transportation. In addition to the exploration of fiber preparation, we are also committed to studying the dyeing of aramid fibers.

Colored aramid yarn

Due to the tight molecular structure and high crystallinity of meta-aramid, it is difficult for small-molecule dyes to enter the interior of the fiber macromolecules, resulting in dyeing difficulties, which hinders the development and application of meta-aramid. Therefore, a lot of research has been done at home and abroad on the preparation of meta-aramid colored fibers. The main directions are to improve the dyeing performance of meta-aramid and adopt dope dyeing and other methods.

At present, a new multi-stage step-by-step coagulation process is being studied to produce aramid colored yarns, which utilizes the diffusion coagulation mechanism of the quaternary spinning slurry spinning stream of polymer/solvent/co-solvent/colorant in the ternary coagulation system. The new process of gradual coagulation forms a moderate skin layer so that the pigment particles remain within the fiber and do not pollute the coagulation bath. This new multi-stage gradual solidification process can produce colored meta-aramid fiber with circular cross-section and dense structure, further improving the mechanical properties of the fiber.

In addition, the industry has also carried out research and discussion on as-spun fiber coloring, meta-aramid fibrid fiber preparation technology, and special-shaped fiber morphological structure control.

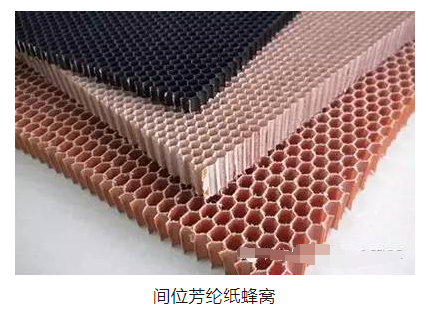

Aramid paper honeycomb attracts much attention

After aramid has received attention from security, filtration and other fields, aramid paper honeycomb has now become the focus of attention from all walks of life – aramid paper honeycomb is the main development direction for lightweight equipment. Lightweight equipment manufacturing can effectively reduce energy consumption. Aramid paper honeycomb is lightweight and has good mechanical properties, flame retardant properties, thermal stability, and electrical insulation properties. Its application can greatly reduce the weight of equipment manufacturing, thereby reducing energy consumption and reducing environmental pollution. Aramid paper has excellent mechanical properties, thermal stability, flame retardant properties, chemical corrosion resistance, radiation resistance and good thermal and electrical insulation properties. The aramid paper honeycomb made of aramid paper through glue coating, lamination, stretching, dipping, curing and sheet cutting has the characteristics of light weight, high strength, flame retardant, low smoke, non-toxic, high temperature resistance, impact resistance, Anti-fatigue, corrosion resistance and other properties. At the same time, due to the structural characteristics of aramid paper honeycomb, it has the functions of sound insulation and heat insulation. The honeycomb sandwich panels produced by it can be widely used in interior ceilings, side wall panels, subdivision panels and other fields.�Aramid paper honeycomb also has excellent wave transmission properties, so it has active applications in radomes. Use adhesive film to bond the skin and aramid paper honeycomb core together. The aramid honeycomb core is tightly bonded to the upper and lower skins to form a skin sandwich panel structure. This structure achieves the perfect combination of stiffness and strength of the board. Can be applied to multiple fields.