Oxford cloth inspection requirements and methods

Oxford cloth inspection requirements and methods

1 Scope

This standard specifies the inspection requirements and inspection methods for Oxford cloth.

This standard is applicable to the incoming inspection of Oxford cloth for making computer bag fabrics or linings.

2 Normative reference documents

The provisions of the following documents become provisions of this standard through reference in this standard. The new versions of the following referenced documents shall apply to this standard.

GB 250 Gray sample card for evaluating discoloration

GB 251 Gray sample card for assessing staining

GB/T 3920 Textile Color Fastness Test Color Fastness to Rubbing

GB/T 3921.1 Textiles Color fastness test Color fastness to washing: Test 1

GB/T 5455 Textiles – Combustion performance test – Vertical method

GB/T 6151 Textiles Color Fastness Test General Test Principles

GB 17591 Flame retardant woven fabrics

ASTM D 4966-1998 Fabric Abrasion Resistance Test

3 Inspection requirements and methods

3.1 Appearance

3.1.1 Inspection requirements

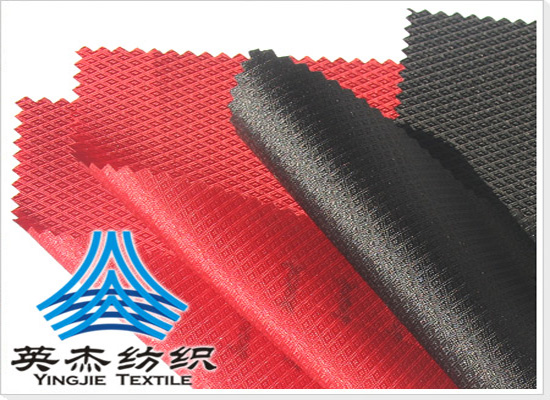

The surface of the Oxford cloth should be clean, dense and even; there should be no obvious color difference, color flowers, dirt, damage and other defects.

3.1.2 Inspection methods

a) In natural light (sufficient indoor light, with large windows and no obstructions to light) or use (3~4) 40W fluorescent lamps with shades, the illumination is not less than 750lx, placed (1~1.2) m above the cloth surface place and inspect under lighting conditions.

b) The sample to be inspected should be spread flat on the table. The inspector looks down at the cloth surface with a distance of 500mm~600mm between the eyes and the cloth surface. The cloth surface should meet the requirements of 3.1.1.

3.2 Density and thickness

Use a density meter to read the number of Oxford cloth yarns per unit length (1 inch); use a thickness meter to test the thickness of 5 different positions of the Oxford cloth, and take the average. The measured density and thickness of the Oxford cloth should comply with the requirements in Table 1.

|

serial number |

Oxford cloth specifications |

Thickness(mm) |

Number of meridional strips (T) |

Number of weft strips (T) |

|

1 |

1680D |

0.45-0.55 |

25 |

19 |

| 15 | ||||

|

Smoldering time, s ≤ |

5 |

10 |

||

|

Note: The assessment level shall be determined according to the product use or through negotiation between the supply and demand parties, and shall be noted in the commissioned test order. B1 is suitable for decorative cloths with special needs; B2 is suitable for various decorative cloths. |

||||

3.4.2 Inspection methods

Take a piece of Oxford cloth with a length of 300mm in the warp direction and a width of 80mm in the weft direction, and a piece of Oxford cloth with a width of 300mm in the weft direction x 80mm in the warp direction, and hang them vertically on the upper part of the alcohol lamp flame to burn for 12 seconds. The height of the alcohol lamp flame should reach 40mm±5mm, and the lower end of the fabric Enter the upper 1/3 of the flame. When leaving the fire source, immediately press the stopwatch to record the afterburning time. When the afterburning stops, immediately press the other stopwatch to record the smoldering time. The reading should be accurate to 0.1s.

The detection method of the damaged length is carried out according to the method of GB/T 5455 8.10, that is, fold the charred part in the length direction of the fabric after burning, and then hang it on the lower end of the sample, about 6mm from the bottom edge and the side edge. Select a weight according to the mass of the sample in square meters, then slowly lift the other side of the lower end of the sample by hand, let the weight hang in the air, then lower it, and measure the length of the tear of the sample, which is the damage length. The hanging weight is selected in Table 1 of Article 6.3 of the standard.

3.4.3 Inspection results

The Oxford cloth being tested shall meet the requirements of 3.4.1.

3.5 Wear resistance

3.5.1 Inspection requirements

The number of frictions at the end of the test shall be no less than 40,000 times measured using a Martindale abrasion tester.

3.5.2 Preparation for inspection

a) Martindale abrasion tester;

b) Standard felt: weight (750±50) g/m2, thickness (3±0.3) mm;

c) Standard friction cloth: combed wool plain weave fabric (gram weight 195 g/m2);

d) Polyurethane foam: density (29~31) kg/m3, thickness (3±0.01) mm, hardness (170~210)N.

e) Inspection sample: Use a sampler with a diameter of 38mm to cut 4 samples.

3.5.3 Inspection methods

3.5.3.1 Place a piece of standard felt with a diameter of 140mm and a standard friction cloth with a diameter of 140mm on each grinding table of the tester. Use a heavy hammer to flatten the friction cloth and felt to ensure there are no wrinkles and secure the ring.

3.5.3.2 Use a sample clamp to clamp the sample and the polyurethane foam of the liner so that the back of the Oxford cloth sample faces down.

3.5.3.3 Place the sample clamp on the grinding table and apply an appropriate pressure of (12±0.3) kPa.

3.5.3.4 Adjust the tester counter to zero, preset 30,000 times, and start the tester. After the tester stops, take out the sample for observation, estimate the number of times required to continue the test, and continue running. When approaching the end of the test, the number of preset samples may be decreased as appropriate. During the test, if there are hair particles on the sample, use medical scissors to carefully cut off the hair particles.

3.5.4 Test termination

3.5.4.1 The Oxford cloth sample is ground until holes appear.

3.5.4.2 Take the average number of frictions at the end of the test for four specimens, which shall not be less than 40,000 times.

3.5.5 Test report

The supplier shall provide a test report or entrust a professional inspection agency to issue a report.

3.6 Waterproof performance

For Oxford cloth with waterproof requirements, cut a 500mm×500mm sample, lay it flat on the table or unfold it by hand. Slowly pour 50ml of 60℃ warm water 150mm above the cloth sample, pat it gently with your hands for 10 seconds, then drain the water or use paper towels to dry it. There should be no water stains on the cloth surface.

3.7 Environmental protection

Fabric samples are required to meet the requirements of the ROHS directive.

Disclaimer:

Disclaimer: Some of the texts, pictures, audios, and videos of some articles published on this site are from the Internet and do not represent the views of this site. The copyrights belong to the original authors. If you find that the information reproduced on this website infringes upon your rights, please contact us and we will change or delete it as soon as possible.

AAA�Property owned by the author. If you find that the information reproduced on this website infringes upon your rights, please contact us and we will change or delete it as soon as possible.

AA