Types and applications of waterproof and breathable fabrics

Types and applications of waterproof and breathable fabrics

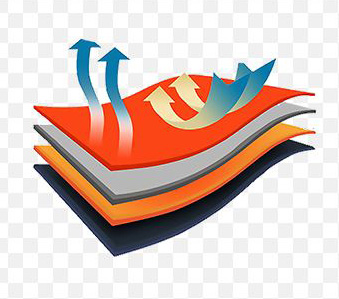

Waterproof and breathable fabric means that when the fabric is worn, water does not penetrate the fabric under a certain pressure, but the sweat emitted by the human body can be transmitted to the outside world in the form of water vapor through the fabric, keeping the wearer dry and comfortable. The reason why waterproof and breathable fabrics are waterproof and breathable is that the diameter of water molecules is larger than the diameter of water vapor molecules. The pores on the surface of the fabric are much smaller than water droplets and much larger than water vapor molecules. Clothing made of such fabrics can not only resist wind , rain, snow, moisture and cold, and breathable, which can prevent people from being overheated or wet during exercise, and calm down immediately after stopping exercise. If it is only waterproof but not breathable, sweat will be trapped in the clothing and make people feel very cold. At the same time, this kind of fabric is also windproof, so that there is a still air layer between the human body and the fabric to keep people warm. If the outer layer of clothing is not windproof, the middle layer will not keep warm and the body will feel cold.

1. Types of waterproof and breathable fabrics

At present, there are three major types of waterproof and breathable fabrics: the first is high-density fabric, which uses high-count cotton yarn and ultra-fine synthetic fibers to make high-density fabrics with high water vapor permeability. After water-repellent finishing, it has a certain Waterproof. It is characterized by good moisture permeability, good softness and drape, but low water pressure resistance, high defective rate, difficulty in dyeing and finishing, and poor hemming and friction resistance. Waterproof and breathable fabrics designed based on this principle include ultra-fine high-density fabrics, ultra-high-density cotton fabrics, etc. The second type is coated fabric, which can be divided into hydrophilic coated fabric and microporous coated fabric. Hydrophilic coating is to apply a hydrophilic coating on the surface of the fabric. Because the coating covers all the gaps in the fabric, it can be waterproof. If there are hydrophilic genes on the polymer chain, with appropriate content and arrangement, they can interact with water molecules, using hydrogen bonds and other intermolecular forces to adsorb water molecules on the high-humidity side, through the hydrophilic gene groups on the polymer chain. Pass to the low humidity side for desorption. Coated fabrics are generally simple to process and are characterized by low moisture permeability and low water pressure resistance. The third type is laminated composite fabric, which combines waterproof, breathable, windproof and warm, and has obvious technical advantages. Using lamination technology to combine ordinary fabrics with E-PTFE to complement each other is the main development direction of waterproof and breathable fabrics.

Currently, there are two types of waterproof and breathable fabrics that are widely used. Judging from the test data, the waterproof and breathable properties of polyurethane (TPU) and polytetrafluoroethylene (PTFE) are equivalent under normal and static conditions. However, during exercise, sweating increases and TPU’s moisture conduction is limited. At low temperatures, In this case, the lower the temperature, the greater the difference. As the temperature drops, the mobility of TPU molecules decreases and shrinks. At 0°C, the moisture conductivity of TPU decreases exponentially. It is almost zero below 0°C. It becomes brittle and easy to break when it reaches minus 15°C. , while E-PTFE will not change at temperatures between minus 150°C and minus 300°C, and its moisture conduction capacity remains basically unchanged. It can discharge water vapor faster and keep you dry and comfortable. At the same time, the micropores of polytetrafluoroethylene are not a straight channel, but the channels form a network structure in the membrane. The wind cannot pass directly. When encountering obstacles, it changes direction and turns back to achieve windproof effect and at the same time play a role in keeping warm. Therefore, E -PTFE is an ideal material for use in harsh environments.

2. Common waterproof and breathable fabrics

(1) Coated fabric

Polyvinyl chloride, polyethylene, polychloroprene and other synthetic rubbers were initially used for waterproof and breathable coated fabrics. However, due to their poor breathability, condensation water is easily formed inside the clothing, causing discomfort such as stuffiness in the human body. comfortability. The thermoplastic polyurethane (TPU) coating developed later has the advantages of good wear resistance, chemical and hydrolysis resistance, low temperature resistance, insect resistance, mildew resistance, easy coloring, and a wide range of process operation options. Regardless of the application scope, Or it has made great progress in improving its own performance and other aspects. Polyurethane is used for coating and finishing of fabrics, and has different forms in terms of raw material type and production process.

1. Microporous coating. The microporous coating mainly causes the polyurethane to form micropores during the film-forming process. The diameter of these micropores can prevent water droplets and allow water vapor molecules to pass through, achieving waterproof and breathable properties. Products currently produced using this method include ENTRANT from Toary Company of Japan, Ultrex from Burlington Company of the United States, Porelle film from Stahi (ICI)/NL Company, and Ucecoat 2000 (S) from UCB Special Chemicals Company of Belgium.

2. Hydrophilic non-porous polyurethane coating. Hydrophilic non-porous polyurethane coating mainly uses hydrophilic groups or hydrophilic components to achieve moisture permeability through the adsorption, transfer and desorption of water molecules. Since there are no micropores in the membrane, the waterproof performance is very good, but the moisture vapor permeability performance needs to be improved. In addition, the disadvantage of this type of coated fabric is that it requires a water-repellent finish on the surface to improve its waterproofness. Such products include Witcoflex Staycool and X-liner produced by the British Baxenden Chemical Company, and Impraperm by the German Bayer Company.

3. A combination of hydrophilic and microporous. This type of product combines the features of microporous coatings and hydrophilic coatings,A layer of hydrophilic non-porous film is added to the porous film, and the microporous film is subjected to hydrophilic finishing to improve the waterproofness of the microporous film. However, the hydrophilic finishing must ensure that it does not affect the original moisture vapor permeability. Such products include the Thintech brand produced by the American 3M Company and the Entrant GII recently developed by the Japanese Toray Company.

4. Shape memory polyurethane non-porous film. The principle of shape memory polyurethane film is to change the moisture permeability of the product as the temperature changes. When the human body temperature changes, the moisture permeability of the product also changes, just like human skin, achieving an intelligent moisture permeability effect. Since the membrane is non-porous, it is very waterproof. For example, Diaplex products produced by Japan’s Mitsubishi Heavy Industries are not only suitable for wearing under normal conditions, but also suitable for wearing under extreme environmental conditions. Its waterproof, breathable and warm performance changes with temperature changes, always maintaining good comfort for the wearer.

(2) Laminated composite fabric

1. GORETEX fabric. The breathable function of GORETEX fabric is achieved through the thin layer of GORETEX film on the fabric. This film is composed of 1.4 billion pores per square centimeter. These pores are 20,000 times smaller than water molecules and 700 times larger than steam molecules. times and arranged irregularly. Therefore, when people exercise outdoors, GORETEX fabric can block rain, snow and cold wind, and continuously discharge sweat emitted by the human body outward, forming a special windproof and waterproof barrier. Ordinary GORETEX fabrics can be waterproof to 2000mm-3000mm water column, and currently some manufacturers in Taiwan and South Korea can even waterproof fabrics to 4000mm-6000mm water column. But the condition for moisture permeability is that the humidity outside the fabric is lower than inside the fabric. Otherwise, the moisture will not only be unable to be discharged, but will also seep back into the clothes. If the surface of the fabric is treated with waterproofing, its moisture permeability will be reduced accordingly. 2. Sympatex fabric. The key point of Sympatex fabric is the use of a film called Neoprotect, which can basically be pressed onto any textile and leather. It is a hydrophilic, non-porous polyester film. Because it is non-porous, it cannot become clogged with detergent residue or other particles, so this occlusive membrane maintains long-term breathability. The principle of waterproofing and breathability is based on the different behaviors of water molecules and water vapor molecules, that is, when they are in a liquid state, they are tightly adsorbed to each other. Therefore, individual molecules cannot adsorb to the positive and negative charges of the film’s molecular chains, while water vapor molecules are very independent of each other and can easily be sucked into the film. Water vapor molecules stick to the positive and negative charges of the film and are expelled to the other side. Through such a physical and chemical process, water vapor molecules are allowed to pass from the inside to the outside, but water from outside cannot enter. Sympatex is famous in Germany and Europe as a windproof, rainproof and breathable fabric.

3. DENTIK FABRIC. DENTIK fabric is developed and produced by the domestic DENTIK company. Its waterproof and breathable principle is basically the same as that of GORETEX fabric. They both use PTFE microporous membrane material. The membrane has many microporous structures, with more than 1 billion holes per square centimeter, and the opening rate is Up to 80%, the pore size is 700 times larger than water vapor molecules, sweat can pass through; the pore size is about 10,000 times smaller than water droplets, liquid water cannot pass through. In this way, DENITK fabric can not only allow the human body to naturally discharge sweat, but also resist the entry of wind, rain and cold current, especially in harsh climate environments, keeping the human body dry and comfortable.

3. Application

1. Military. Waterproof and breathable fabrics were first developed and used in the production of military uniforms and protective clothing. For air force pilots, navy soldiers and special forces, sudden immersion in cold water can cause hypothermia and is one of the important factors causing casualties. Waterproof and breathable clothing has been used as special anti-riot clothing for U.S. Air Force pilots, crew members and special forces performing sea, land and air operations. These garments provide protection for up to 2 hours in cold water up to 70C and are lightweight and comfortable to wear. The application of waterproof and breathable fabrics not only solves the contradiction between breathability and waterproofing, but also reduces the weight of the raincoat, thereby effectively reducing the load of soldiers.

2. In civilian use. Waterproof and breathable fabrics are mostly used in civilian products such as tents, sleeping bags, jackets, shoes, etc. For example, outdoor sleeping bags require warmth, breathability, and light weight. They are based on PTFE microporous membrane laminated fabric and adopt a double-layer structure. The outer layer is nylon fabric and the inner layer is PTFE membrane. There is no risk of hypoxia or carbon monoxide poisoning when using this sleeping bag. Because the PTFE material has excellent chemical resistance and flame retardant properties, and the microporous structure of the film makes it more waterproof and breathable, it has become an ideal material for the development of nuclear, biological and chemical protective clothing. Waterproof and breathable laminated fabrics can not only meet the wearing needs of people during activities in harsh environments such as severe cold, rain, snow, and windy weather, but are also suitable for people’s daily life requirements for raincoats, footwear, etc., and have broad application and development prospects. In the future, the research and development of waterproof and breathable fabrics will focus on reducing costs and working towards making them more lightweight, comfortable and multi-functional. Waterproof breathable fabric is a high value-added product with a wide range of applications. The waterproof and breathable products produced by different production processes have their own characteristics, and there are also imperfections. This requires the majority of scientific and technological workers to continue to work hard to develop more comfortable and functional fabrics to meet people’s increasing needs. growing demand.

Disclaimer:

Disclaimer: Some of the texts, pictures, audios, and videos of some articles published on this site are from the Internet and do not represent the views of this site. The copyrights belong to the original authors. If you find that the information reproduced on this website infringes upon your rights, please contact us and we will change or delete it as soon as possible.

AAA

Disclaimer: Some of the texts, pictures, audios, and videos of some articles published on this site are from the Internet and do not represent the views of this site. The copyrights belong to the original authors. If you find that the information reproduced on this website infringes upon your rights, please contact us and we will change or delete it as soon as possible.

AA