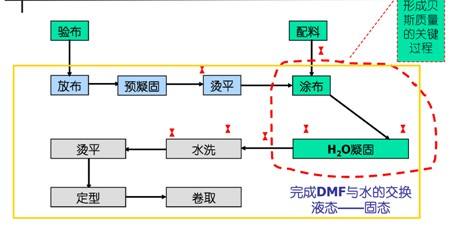

PU synthetic leather wet production process flow

PU synthetic leather wet production process

Dry method:

The synthetic leather dry production line uses PU resin coating method to coat release paper with various textures. After drying and pasting, it is then pasted together using base fabric (knitted fabric, non-woven fabric) as the base material. Combining, drying and other processes make the pattern of the product the same as that of various release papers, and then undergo printing processing to make it comparable to real leather in terms of touch, toughness and appearance.

Product Usage

Shoes, bags, furniture, clothing, sports equipment, etc.

Mechanical Characteristics

1. High-precision coating machine

Equipped with an automatic feeding system and automatic precision monitoring and control, the coating accuracy is uniform and accurate.

2. Laminating machine

Specially designed, the base fabric is rolled out without tension, making the base fabric flat and with stable tension. The laminating equipment has two functions: strong pasting and hanging pasting (soft pasting), which enables better quality and higher yield when selecting base fabrics and products.

3. Hot air circulation drying furnace device

Fully automatic computer temperature control, accurate and even temperature, combined with good thermal insulation effect, saves heat sources.

4. Cutting center coiling machine

Cutting and joining materials are safe and efficient, easy to operate, and reduce the loss of finished products.

5. Driving tension

Fully automatic tension air pressure control system, stable tension and low probability of paper breakage.

Technical Parameters

1. Mechanical wheel spoke Max: 1700mm;

2. Product width Max: 1450mm;

3. Mechanical speed Max: 30m/min;

4. Oven length: 10m, 15m, 25m

5. Transmission system: full line linkage of variable frequency motors;

6. Unit composition: agreed upon by the user when ordering;

7. Total supporting power: 150kw.

Purpose:

This production line consists of units such as uncoiling, gluing, fabric splicing, deviation adjustment, drying, post-traction, fabric combining, coiling, exhaust, and control systems. It is mainly used for rubber sheet gluing operations. It can meet the three operation requirements of single coating, overcoating and combined coating.

Performance features:

Using the gap forming method, the slurry is applied to the base fabric when the base fabric passes through the gap formed between the rubber coating roller and the coating blade. Knife gap closed-loop automatic tracking, digital display. It has compact structure, advanced control, safety and explosion-proof, and complete functions. The temperature control has PID calculation function, the operation control adopts a programmable controller (PLC), and the speed control system adopts a frequency converter for speed regulation. The control accuracy is high, the operation is stable, and the running speed is digitally displayed, which is intuitive and clear. The unique heating and drying system has extremely high thermal efficiency, ensuring high productivity of the entire system.

Main technical parameters

1. Effective width of roller surface: 1800-2200mm

2. Gluing width (max): 1600-2000mm

3. Gluing speed: 3~30m/min frequency control, forward and reverse operation

4. Glue thickness: min: 0.1mm, max: 0.8mm

5. Glue coating accuracy: ±0.01mm

6. Form of scraper: comma knife

7. Diameter of rubber coating roller: φ400mm

8. Large gap between coating blade and roller surface: 80mm

9. Job requirements: single coating, overcoating, combined coating

10. Maximum length for overcoating: 50-80m

11. Unwinding diameter (max): φ400mm

12. Rewinding diameter (max): φ700mm

Wet method:

The method includes the following steps: first, evenly cover a layer of PU resin on the textile fiber cloth, and then immerse the textile fiber cloth covered with PU resin into a coagulation tank filled with water. When the PU resin layer is in a semi-solidified state, , use a mold with a pattern engraved on the surface to perform embossing treatment on the PU resin layer, and then take out the textile fiber cloth and put it into a washing tank to further mature it, thereby obtaining PU synthetic leather with a three-dimensional pattern on the surface; the invention can reduce The production cost of synthetic leather simplifies its production process; and the texture of the processed synthetic leather has a strong three-dimensional effect, making it closer to the natural texture of natural fur.

Sovereignty

Claim 1. A processing method for wet PU synthetic leather, characterized in that the method includes the following steps: first, evenly cover a layer of PU resin on the textile fiber cloth, and then cover the textile fiber cloth covered with the PU resin. Immerse in the solidification tank filled with water. When the PU resin layer is in a semi-solidified state, use a mold with a pattern engraved on the surface to emboss the PU resin layer. Then take out the textile fiber cloth and put it into the water washing tank. After further maturation, PU synthetic leather with three-dimensional patterns on the surface is obtained.

Wet polyvinyl butyral synthetic leather

Summary

A polyvinyl butyral synthetic leather is made of synthetic fiber non-woven fabric impregnated with latex containing polyvinyl butyral resin as the main material. It has good rigidity, high strength, breathability and water resistance. It can replace natural leather and other alternative materials for the main body, toe cap and lining of leather shoes. It will not deform when exposed to water, keeping the leather shoes beautiful and comfortable to wear. Moreover, it is easy to make, has a simple process, is pollution-free, has low cost, has good activation performance and is easy to process. It is an ideal substitute material for making main heels, toe caps and shoe linings. It can reduce the cost of shoemaking and improve the wearing performance of shoes.

Synthetic leather dry and wet production line process and each step:

1. Evenly cover the textile fiber cloth with a layer of PU resin,

2. Immerse the textile fiber cloth covered with PU resin into a solidification tank filled with water. When the PU resin layer is in a semi-solidified state, 3. Use a mold with a pattern engraved on the surface to emboss the PU resin layer. processing,

4, take out the textile fiber cloth, put it into the washing tank, and let it mature further, that is, PU synthetic leather with a three-dimensional pattern on the surface is obtained.

Function: This invention can reduce the production cost of synthetic leather and simplify its production process; and the texture of the processed synthetic leather has a strong three-dimensional effect, making it closer to the natural texture of natural fur. werwrgsd

Disclaimer:

Disclaimer: Some of the texts, pictures, audios, and videos of some articles published on this site are from the Internet and do not represent the views of this site. The copyrights belong to the original authors. If you find that the information reproduced on this website infringes upon your rights, please contact us and we will change or delete it as soon as possible.

AA