38. What are the conveniences of using resin cross-linking indicator Hl2? How to use it?

Answer Resin cross-linking indicator Hl-2 is an indicator jointly developed by the former China Textile University and Shanghai Printing and Dyeing Industry Company that can quickly, sensitively, easily and intuitively test the correlation between the cross-linking degree of resin and fabric.

Resin finishing of fabrics is a colorless finishing, and its effect cannot be directly judged with the naked eye. The finishing effect is usually evaluated by measuring the tear strength, wrinkle recovery, shrinkage and formaldehyde content of the fabric. The resin cross-linking indicator HI-2 can be used to directly determine the degree of cross-linking by dripping or coloring methods to identify different indicators. How to use it is as follows.

①Sample planning. Cut a 5cmX 5cm sample from the white fabric sample that has been treated with resin, weigh it, press half of the sample area with a 175°C iron for 1 minute, and cool it for use.

② Prepare HI-2 dye solution. Accurately weigh several grams of Hl-2, add 200 times the amount of water, stir evenly to dissolve it, and prepare a dye liquor of Hl-20.5%. Take the required amount of dye liquor, heat it to boiling, and set aside.

③Operation. Put the prepared sample into the boiling HI-2 dye bath at a liquor ratio of 1:60 and stir continuously. Boil and dye for 2 minutes. Pour off the dye liquor, wash away the floating color on the surface with hot and cold water, and then dry it.

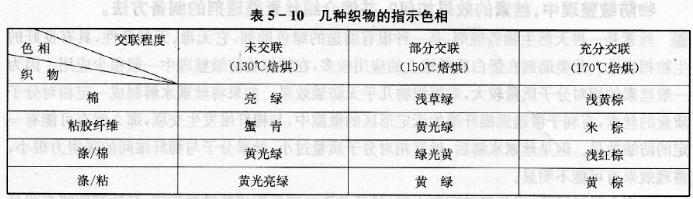

④Judgement of cross-linking degree. After the resin-finished fabric is colored with HI2, it will show different colors due to different degrees of cross-linking. Generally speaking, uncrosslinked samples appear green; partially crosslinked samples turn toward grass green; fully crosslinked samples turn toward yellow or reddish brown. For example, several fabrics are finished with N-hydroxymethyl resin and then colored with HI-2 to show different hues, as shown in Table 5-10.

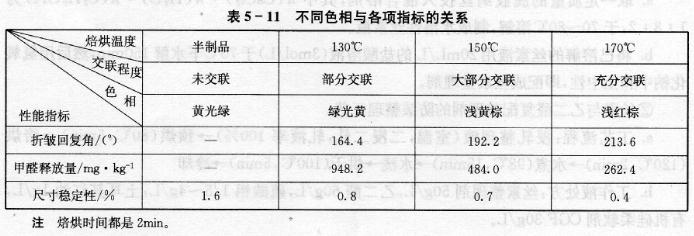

⑤The relationship between hue and physical and mechanical properties. After the polyester/cotton cloth is treated with 2D resin, due to the adoption of different baking temperatures, the relationship between different hues and various indicators obtained after coloring with HI-2 is shown in Table 5-11.

Using Hi-2 is suitable for white fabrics. If it is a colored fabric, you can sew a white fabric sample of the same specification and variety that has been pre-treated but not colored on the colored fabric. When using the Hl-2 coloring method to identify the cross-linking properties of resin, it is best to have the factory make a color card in advance for accurate comparison.

AAA4353466DG

Disclaimer:

Disclaimer: Some of the texts, pictures, audios, and videos of some articles published on this site are from the Internet and do not represent the views of this site. The copyrights belong to the original authors. If you find that the information reproduced on this website infringes upon your rights, please contact us and we will change or delete it as soon as possible.

AA