Textile dictionary – polyacrylonitrile fiber (acrylic fiber)

Many people have misunderstandings or understanding of “Textile Dictionary – Polyacrylonitrile Fiber (Acrylic Fiber)“. Let me take you with me to share it with your friends and explore more about ” Textile Dictionary – Polyacrylonitrile Fiber (Acrylic Fiber)” knowledge…

Acrylic fiber is the trade name of polyacrylonitrile fiber in my country, and abroad it is called “Aolun” and “Cashmeron”. Usually refers to synthetic fibers made by wet spinning or dry spinning using a copolymer of more than 85% acrylonitrile and the second and third monomers. The fiber produced by spinning a copolymer with an acrylonitrile content between 35% and 85% is called modified polyacrylonitrile fiber.

Introduction

It is what is usually called “acrylic fiber (jīnglún). English name: polyacrylonitrilefiber

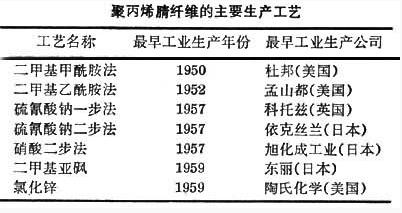

The main production process of acrylic fiber: polymerization → spinning → preheating → steam drawing → washing → drying → heat setting → curling → cutting → packaging. The performance of polyacrylonitrile fiber is very similar to that of wool. It has good elasticity. When stretched by 20%, the rebound rate can still maintain 65%. It is fluffy, curly and soft. Its warmth retention is 15% higher than that of wool. It is called synthetic wool. The strength is 22.1~48.5cN/dtex, 1~2.5 times higher than wool. It has excellent light fastness. When exposed to the sun for one year, its strength will only decrease by 20%. It can be made into curtains, curtains, tarpaulins, gun jackets, etc. It is resistant to acids, oxidants and general organic solvents, but has poor alkali resistance. The fiber softening temperature is 190~230℃.

Acrylic fiber is also known as artificial wool. It has the advantages of soft, bulky, easy to dye, bright color, light resistance, antibacterial, and not afraid of insects. It can be spun purely or blended with natural fibers according to the requirements of different uses. Its textiles are widely used in clothing, decoration, industry, etc. field.

Polyacrylonitrile fiber can be blended with wool to make yarn, or woven into blankets, carpets, etc. It can also be blended with cotton, man-made fibers, and other synthetic fibers to be woven into various clothing materials and indoor products. The expanded top processed by polyacrylonitrile fiber can be spun purely or blended with viscose fiber and wool to obtain various specifications of medium-thick yarn and fine yarn “cashmere”.

Difference

1. Viscose (hygroscopic and easy to stain)

It is a man-made cellulose fiber produced by solution spinning. Due to the inconsistent solidification rate of the fiber core layer and the outer layer, a skin-core structure is formed (which can be clearly seen from the cross-sectional slice). Viscose is the most hygroscopic among ordinary chemical fibers. It has good dyeability and good wearing comfort. However, viscose has poor elasticity, wet strength and abrasion resistance. Therefore, viscose is not resistant to washing and has poor dimensional stability. The specific gravity is heavy, the fabric is heavy, and it is resistant to alkali but not acid.

Viscose fiber is widely used and is used in almost all types of textiles, such as filament for lining, beautiful silk, flags, streamers, tire cord, etc.; short fiber for cotton-like, wool-like, blended, interwoven, etc.

2. Polyester (stiff and wrinkle-free)

Features: high strength, good impact resistance, heat resistance, corrosion resistance, moth resistance, acid and alkali resistance, very good light resistance (second only to acrylic fiber), 1000 hours of exposure, strength retention of 60-70%, poor hygroscopicity , dyeing is difficult, the fabric is easy to wash and quick-drying, and has good shape retention. It has the characteristics of “wash and wear”

Usage:

Filament: often used as low elasticity yarn to make various textiles;

Staple fiber: cotton, wool, linen, etc. can be blended, industrially: tire cord, fishing nets, ropes, filter cloth, insulating materials, etc. Polyester is currently the most widely used chemical fiber.

3. Nylon (strong and wear-resistant)

The biggest advantage is that it is strong and wear-resistant, which is the best kind. The density is small, the fabric is light, the elasticity is good, it is resistant to fatigue damage, the chemical stability is also very good, and it is resistant to alkali but not acid!

The big disadvantage is that the sunlight resistance is not good, the fabric will turn yellow if exposed to the sun for a long time, the strength will decrease, and the moisture absorption is not good, but it is better than acrylic and polyester.

Usage: filament, mostly used in knitting and silk industry; short fiber, mostly blended with wool or wool-type chemical fiber, used as gabardine, vanidine, etc. Industry: cords and fishing nets, can also be used as carpets, ropes, conveyor belts, screens, etc.

4. Acrylic fiber (bulky and light-fast)

The properties of acrylic fiber are very similar to wool, so it is called “synthetic wool”.

Molecular structure: Acrylic fiber is very unique in its internal structure. It has an irregular spiral conformation and does not have a strict crystalline region, but it can be divided into high-order and low-order arrangements. Because of this structure, acrylic fiber has good thermal elasticity (can be processed into bulked yarn), acrylic fiber has a low density, smaller than wool, and the fabric has good warmth retention.

Characteristics: Excellent sunlight resistance and weather resistance (highest), poor moisture absorption, and difficult to dye.

Pure acrylic fiber has a tight internal structure and poor wearability. Therefore, its performance is improved by adding a second and third monomer. The second monomer improves elasticity and feel, and the third monomer improves dyeability.

Usage: Mainly for civilian use, it can be spun purely or blended to make a variety of woolen materials, woolen yarns, blankets, and sportswear. It can also be used for: artificial fur, plush, bulked yarn, hoses, parasol cloth, etc.

5. Vinyl (water-soluble moisture absorption)

The biggest feature is. Enhance the toughness and low temperature resistance of asphalt concrete:

4. Improve the toughness and low temperature resistance of asphalt concrete:

5. Reduce durable deformation and improve anti-slip and wear resistance:

6. Reduce the impact of temperature on asphalt pavement and improve the water stability of asphalt concrete:

7. Improve the crack resistance of mud-free concrete:

8. Improve the frost resistance, durability, impermeability, etc. of cement concrete and mortar:

9. Reduce the brittleness of cement concrete and ensure the strength of cracked concrete;

10. Improve the durability, tensile strength and toughness of concrete;

11. Improve impact resistance, earthquake resistance and crack resistance.

Construction Suggestions

Amount of cement concrete

① Generally, the dosage of concrete per cubic meter is 0.5-1.0kg.

②According to the changes in the amount of sand, stone, and cement used to meet the anti-cracking requirements of the project, the amount of fiber can be adjusted appropriately, with a maximum of 1.5kg/m³.

Suggestion: Different base material particle gradations have a great influence on the blending effect, so choose a good gradation as much as possible.

Application fields

High-performance concrete road pavements, bridge panels, airport pavements, rockfill dam panels, earthquake-resistant and explosion-proof cement concrete projects

High-grade asphalt pavement projects such as highways, municipal roads, airport pavements, bridge deck paving, toll stations, etc.

AAASLKFJWELR

Through the above review of “Textile Dictionary – Polyacrylonitrile Fiber (Acrylic)

b>”, what is your understanding and thoughts about “Textile Dictionary – Polyacrylonitrile Fiber (Acrylic Fiber)“, or you are interested in purchasing fabrics, You are welcome to post your comments below the website!

Disclaimer:

Disclaimer: Some of the texts, pictures, audios, and videos of some articles published on this site are from the Internet and do not represent the views of this site. The copyrights belong to the original authors. If you find that the information reproduced on this website infringes upon your rights, please contact us and we will change or delete it as soon as possible.

AA