In the context of environmental protection where the world is advocating energy conservation and emission reduction, solar energy is developing the fastest , new energy sources with great potential have received support from various aspects such as policies and funds. Today we will learn about the material PTFE solar module film.

Semiconductors are used in most electronic products, including computer chips, audio amplifiers, temperature sensors and solar cells. Traditionally, photovoltaic modules have been manufactured using various forms of silicon, but many companies are also manufacturing modules using other semiconductor materials, often referred to as thin film photovoltaics. Each photovoltaic technology has unique cost and performance characteristics, which drive competition within the industry. The specific configuration of the PV application and PV system may further impact cost and performance.

PTFE solar module films are widely used in sealing, electronics, biomedical, textile, environmental protection and other fields. Because of its acid, alkali and corrosion resistance, it can adapt to harsh environments, so its application in environmental protection is particularly prominent. However, polytetrafluoroethylene has low surface energy and poor surface wetting properties, making it unsuitable for bonding, which greatly limits its application. It is widely used in environmental protection, medicine, chemical industry and other aspects.

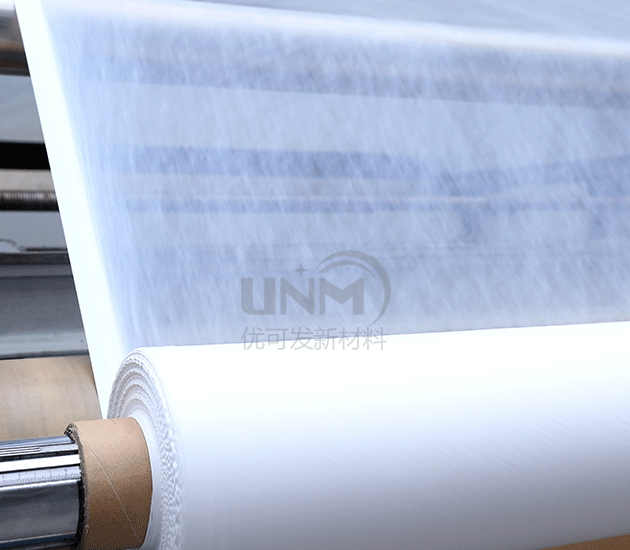

Suzhou New Material Technology Co., Ltd. is a fluorine material film that integrates the research, development, production and sales of ptfe solar module films, ptfe bubble point films, polytetrafluoroethylene films, Teflon films and coated filter materials. factory. The company has advanced PTFE film production lines, lamination and composite production lines, which are at the domestic advanced level. The company’s products are widely used in various fields. Interested parties can enter the store for consultation and purchase! </p