Energy saving, emission reduction, innovation | CV Alliance promotes the sustainable development of the regenerated cellulose fiber industry chain into a new stage

The mountains and rivers are more suitable for guests. On April 25, the “Viscose Fiber Industry Standard Conditions” research symposium and the “CV Alliance Green Production Journey – Siliya Station” were held in the beautiful Yibin. Zheng Junlin, Vice President of China Chemical Fiber Industry Association, He Yanli and Jiang Junzhou, former Vice Presidents; Wu Tong, Level 4 Researcher of the Textile Division of the Department of Consumer Goods Industry, Ministry of Industry and Information Technology; Hu Bo, Deputy Secretary of the Party Committee and General Manager of Yibin Siliya Group Co., Ltd. , Deputy General Manager Song Wei; CV Alliance Chairman Unit, Executive Deputy General Manager of Tangshan Sanyou Group Xingda Chemical Fiber Co., Ltd. Zhang Dongbin, as well as representatives from Tangshan Sanyou, Sateri, Zhongtai Textile, Shandong Yamei, Weifang Xinlong, Jilin Chemical Fiber, Shandong About 70 people participated in the event, including representatives from regenerated cellulose fiber companies such as Yinying, Xinxiang Chemical Fiber, Lenzing (Nanjing), and Birla Jingwei, as well as upstream and downstream companies in the industry chain such as Septwolves Knitting, Luolai Life, and Yibin Huimei.

Playing the “Chorus” of the industry’s green development image

Picture | Zheng Junlin, Vice President of China Chemical Fiber Association

“The chemical fiber industry has always attached great importance to the energy conservation and emission reduction and green development of the regenerated cellulose fiber industry. The promulgation and implementation of the “Viscose Fiber Industry Specifications and Conditions” have laid a solid foundation for the energy conservation of the industry. It has made important contributions to emission reduction and guided the direction of green development of the industry. The CV Alliance has established upstream and downstream enterprises in the domestic and foreign textile industry chain by carrying out industry exchange visits, brand docking, stakeholder communication, and preparation of industry sustainable development reports. It has a wide impact.” Zheng Junlin, vice president of China Chemical Fiber Association, said in his speech.

Picture | Zhang Zixin, director of the Science and Technology Department of China Chemical Fiber Association and secretary-general of CV Alliance

Under the leadership of the CV Alliance (Regenerated Cellulose Fiber Industry Green Development Alliance), my country’s regenerated cellulose fiber industry has been at the forefront of the industry in its understanding and actions of sustainable development. A number of CV Alliance member companies have begun to systematically promote the construction of corporate sustainable management systems, and have established interests in the company’s “dual carbon” goals, closed-loop clean production, sustainability report preparation, product carbon footprint tracing, and sustainable brand design. Substantial progress has been made on the issues that concern the most. Zhang Zixin, director of the Science and Technology Department of the China Chemical Fiber Association and secretary-general of the CV Alliance, introduced the implementation of the “Viscose Fiber Industry Standard Conditions”, reviewed the alliance’s work overview, and looked forward to the alliance’s follow-up work priorities. In the future, alliance member companies will continue to communicate with stakeholders, disclose industry sustainable development information, and improve the industry’s sustainable development level. At the same time, the CV Alliance will pay more attention to hot topics such as carbon footprint and high-value utilization of waste textiles.

During the free speech session, representatives from regenerated cellulose fiber companies such as Tangshan Sanyou, Sateri, Zhongtai Textile, Shandong Yamei, Weifang Xinlong, Jilin Chemical Fiber, Shandong Yinying, Xinxiang Chemical Fiber, Lenzing (Nanjing), and Birla Jingwei They exchanged views on key issues such as the implementation of the “Viscose Fiber Industry Standard Conditions”, industry technological progress trends, product application progress, and pulp localization research.

Picture | Wu Tong, a fourth-level researcher at the Textile Division of the Department of Consumer Goods Industry of the Ministry of Industry and Information Technology

Wu Tong, a fourth-level researcher at the Textile Division of the Consumer Goods Industry Department of the Ministry of Industry and Information Technology, said: “The “Viscose Fiber Industry Standard Conditions” is an important starting point for the Ministry of Industry and Information Technology to guide the green and sustainable transformation of the industry, and plays an important role in guiding the industry to save energy and reduce emissions; the association promotes The work of the CV Alliance uses a more innovative and market-oriented approach to make the concept of green sustainability not only a corporate social responsibility, but also a real economic value. The Ministry of Industry and Information Technology is happy to see the CV Alliance as an industry leader in green development. The innovative model will also provide more support to the CV Alliance and member companies, and provide good command, so that the ‘chorus’ of green development in the industry will sing louder and louder.”

Regarding the future development of the viscose fiber industry, he pointed out that under the current environment, expanding the demand for downstream industrial chains is still a top priority. To this end, one is to drive quality improvement through technological innovation and further strengthen downstream recognition and recognition of fiber.=”text-align: center;”>

Picture | Tang Chunyan, Product Manager of Septwolves Knitting Co., Ltd.

Tang Chunyan, product manager of Septwolves Knitting Co., Ltd., shared green sustainable concepts and innovative ideas for product development in the field of home knitting. Septwolves continues to launch a series of green and environmentally friendly products, all of which are made from certified or controlled renewable wood sources. For example, its paper yarn is made from FSC-certified paper through multiple processes, and then the paper yarn is woven into high-quality paper fiber. Socks, products can not only create benefits for society but are also environmentally friendly. In addition, she also introduced the research and development practice of new products using natural colored cotton, Tencel, bamboo pulp fiber, modal fiber and other new products combined with national trend cultural elements.

Picture|Luolai Life Technology Co., Ltd.

Senior R&D Director Gong Huairui

Gong Huairui, senior R&D director of Luolai Life Technology Co., Ltd., introduced the R&D and innovative applications of viscose fiber in the field of home textiles, and shared the performance characteristics of various products and the application technical requirements for viscose fiber, such as in home furnishings In product application, siro spinning, compact spinning and other processes can be used to make the quality index of viscose fiber yarn meet the requirements of knitting yarn; by optimizing the process parameters of each part and selecting appropriate spinning accessories, the yarn line, strength, and strength can be improved. Hairiness and other quality indicators. In addition, he also introduced the innovative applications of viscose-based functional fibers in the field of home textiles such as antibacterial, phase change temperature regulation, negative ions, high adsorption and odor removal, and healthy skin care.

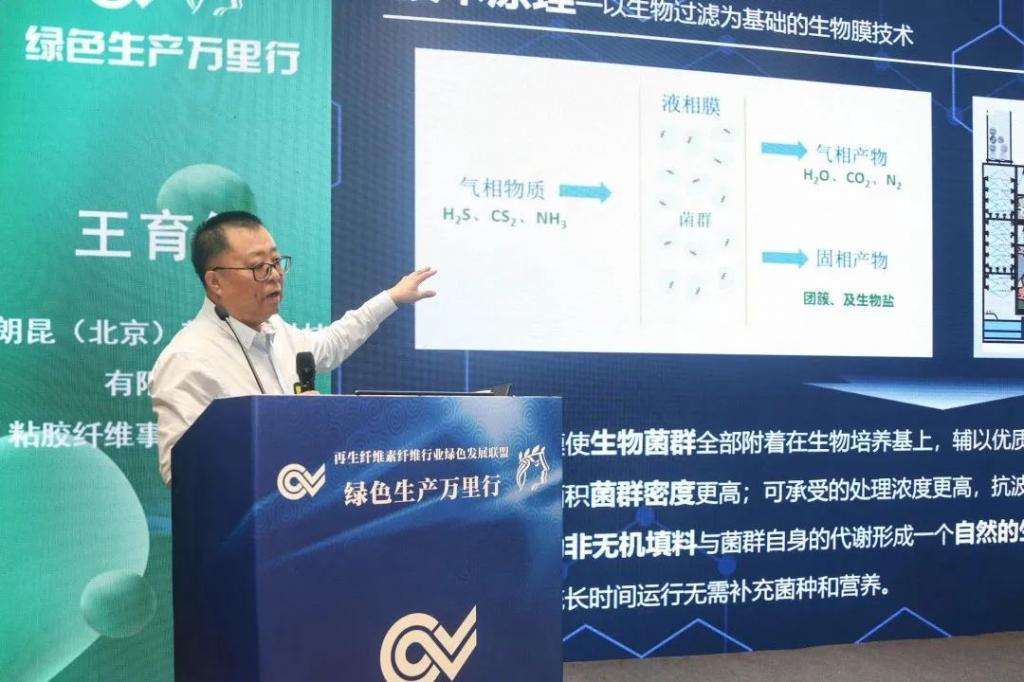

Picture | Langkun (Beijing) New Environmental Protection Technology Co., Ltd.

Wang Yuhong, general manager of the viscose fiber business unit

Wang Yuhong, general manager of the viscose fiber division of Langkun (Beijing) New Environmental Protection Technology Co., Ltd., shared the application case of Langkun’s biological technology in the treatment of waste gas in the viscose fiber industry. He said that Lancun biotechnology has three major advantages. First, it can process mixed gases containing hydrogen sulfide and carbon disulfide at the same time; second, it can solve the problem of meeting emission standards for low-concentration production waste gas in the viscose fiber industry; third, it can handle lower-concentration gases. When producing waste gas, a higher level of environmental protection can be achieved. At present, this technology is applied in Yibin Heist, Xinxiang Chemical Fiber, Zhongtai Textile and other enterprises.

Related links: Enter Siliya

On April 26, representatives from CV Alliance member units and upstream and downstream enterprises of regenerated cellulose fiber visited Yibin Yashide Textile Co., Ltd., Yibin Liya Sanitary Material Technology Co., Ltd., and Yibin Siliya Co., Ltd. for visits and exchanges.

AAA fabric networkSDGGERY6UFGH

Disclaimer:

Disclaimer: Some of the texts, pictures, audios, and videos of some articles published on this site are from the Internet and do not represent the views of this site. The copyrights belong to the original authors. If you find that the information reproduced on this website infringes upon your rights, please contact us and we will change or delete it as soon as possible.

AA