With its resource-intensive, energy-intensive, large-scale production and large logistics throughput, the foundry industry has long been regarded as an enterprise with large emissions of smoke, waste, and pollution. For this reason, many companies in this field Companies will use bag dust removal technology to solve emission problems, and the polytetrafluoroethylene dust removal membrane plays an important role here.

The equipment that separates industrial dust from flue gas is called industrial dust collector or industrial dust removal equipment. The performance of the dust collector is expressed in terms of the amount of gas that can be processed, the resistance loss when the gas passes through the dust collector, and the dust removal efficiency. At the same time, the price, operation and maintenance costs, service life and difficulty of operation and management of the dust collector are also important factors when considering its performance.

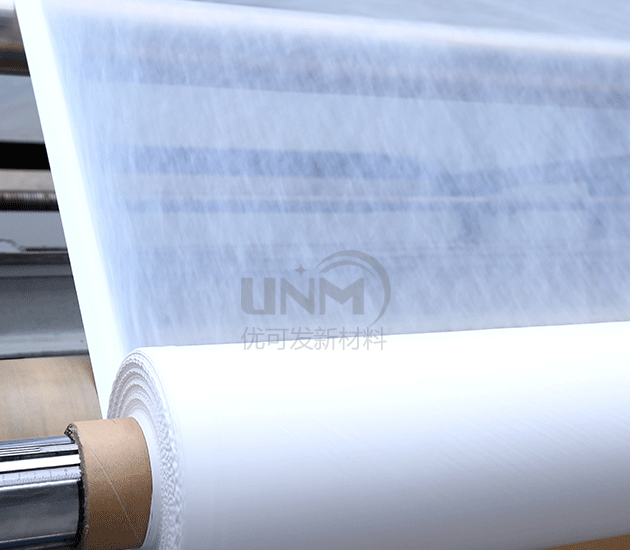

Polytetrafluoroethylene dust removal membrane is suitable for various clean rooms from level 1 to level 100,000. It adopts special processing technology and undergoes calendering, extrusion and bidirectional stretching. A microporous film made by other methods. This kind of membrane has excellent breathability, corrosion resistance, aging resistance, high temperature resistance and other properties. According to the usage requirements, the pore diameter can be between 0.1-10um, the thickness can be between 2-100um, the porosity can reach 50%–80%, and there are up to hundreds of millions of micropores per square centimeter.

The polytetrafluoroethylene dust removal membrane produced by the manufacturer uses imported raw materials, has a full set of advanced production equipment, an advanced clean room and an independent composite separation system. The cutting workshop ensures the production quality of PTFE film; it uses production testing instruments imported from the United States to test the quality of PTFE film, and has passed international SGS testing and certification, as well as ISI testing and certification. Interested parties can enter the store and contact us.

</p