Waterproof and breathable fabrics used in outdoor sports and leisure clothing must not only be waterproof and breathable, but also must have a certain degree of comfort. ptfe clothing film manufacturerptfe clothing film can meet these conditions.

Functional fabric, in harsh conditions environment, it can isolate the human body from rain, snow, and chemicals while also transmitting water vapor to the outside world. The performance differences between waterproof and breathable fabrics determine the final application range. Structurally, it can be divided into microporous materials (including polytetrafluoroethylene PTFE microporous membrane, polyurethane PU microporous membrane, ultra-dense fabric, polyethylene PE porous membrane) and non-porous materials (thermoplastic polyurethane TPU hydrophilic non-porous membrane ), as well as microporous and non-porous composite materials (PTFE microporous membrane + PU non-porous membrane, fabric + hydrophobic treatment agent coating, PP + PE porous membrane + PP laminate composite). From the molding process, it can be divided into ultra-dense fabric weaving, stretching into holes, disordered fiber accumulation into holes, coating, and lamination.

Knitted velvet fabrics can be formed by a variety of methods. Among them, there are two main methods of weft knitting to form plush fabrics: top feeding and wool yarn cutting. The pile height of the in-type fabric is larger, but the product has greater elasticity and needs to be sized and shaped at the bottom; the pile height of the cut loop fabric is smaller, but the dimensional stability is improved; the warp knitting method of forming velvet fabrics mainly includes raising , split and sheared piles, etc. Among them, pile fabrics can obtain longer piles, good air permeability, stable structure, good elasticity and extensibility.

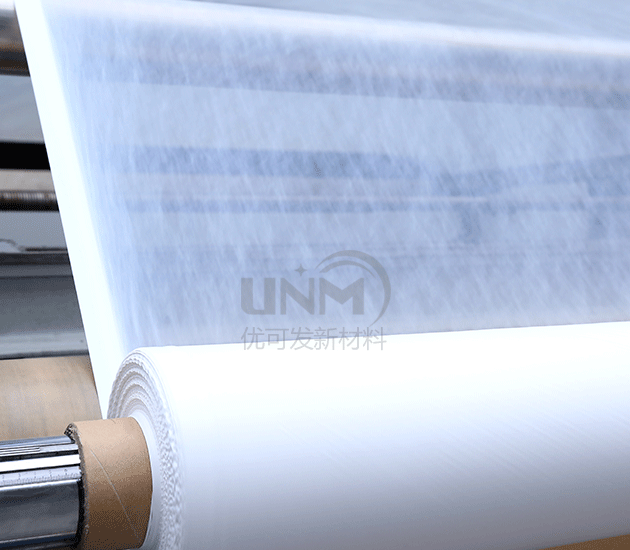

ptfe clothing film manufacturerThe product is a polymer compound made of polytetrafluoroethylene. It is calendered and Microporous membranes made by extrusion, biaxial stretching and other methods. The film also has excellent corrosion resistance, aging resistance and high temperature resistance, and the operating temperature can reach -150℃-250℃. It has been widely used in many fields such as electronics, chemical industry, medicine, military, aerospace, clothing, environmental protection and so on.

ptfe clothing film manufacturerDuring the stretching process, the film forms nodes and A microporous structure connected by countless microfibers, pores are formed between the microfibers, and the pores penetrate each other to form a unique network structure. Wind cannot pass directly, and will change direction and turn back when it encounters an obstruction, preventing air from penetrating, so it has excellent windproof performance. Interested parties can enter the store for consultation and purchase!

</p