Teflon is also called polytetrafluoroethylene. This material is a neutral high-quality material with a special molecular structure that is completely symmetrical. Molecular compounds. The special structure makes it have good thermal stability, chemical stability, insulation, lubricity, water resistance, etc. High temperature resistance, wide operating temperature range, can be used continuously for a long time at 260℃ (high temperature, instantaneous temperature can reach 280℃); strong chemical stability, corrosion resistance; good self-lubricating, extremely low friction coefficient, little filter wear; PTFE The surface tension of the film is very low, and it has good non-stickiness and water repellency.

Teflon bubble point membrane In the state of water vapor, the water particles are very small, and these water particles can penetrate all the way down the capillary to the other side , the phenomenon of breathability occurs. If water vapor condenses and turns into water droplets, the particles will become larger. In addition, the surface tension of the water droplets will act, and the water molecules will not be able to smoothly leave the water droplets, penetrate and reach the other side. In other words, This process can prevent water penetration, making the Teflon foam membrane truly waterproof.

The working principle of liquid bag filtration is pressure filtration. The entire bag filtration system consists of three parts: filter container, support basket and filter bag. The filtered liquid is injected into the container from the top and flows from the bag to the outside of the bag evenly. Distributed on the entire filtration surface, the filtered particles are trapped in the bag without leakage. It has a user-friendly and convenient design, exquisite overall structure, efficient operation, large processing capacity, and long service life. It is a leading energy-saving product in the liquid filtration industry and is suitable for For coarse filtration, intermediate filtration and fine filtration of any fine particles or suspended matter.

PTFE coated filter material can Surface filtration is achieved because the PTFE-coated filter material has a microporous structure and no through-holes on the surface, so dust cannot enter the interior of the membrane or the base material through the surface of the membrane, so only gas passes through and the dust or materials are trapped. The surface of the membrane. At present, membrane-coated filter materials have been widely used in many fields such as industrial dust removal and precision filtration. What I have to say is Teflon foam dot film.

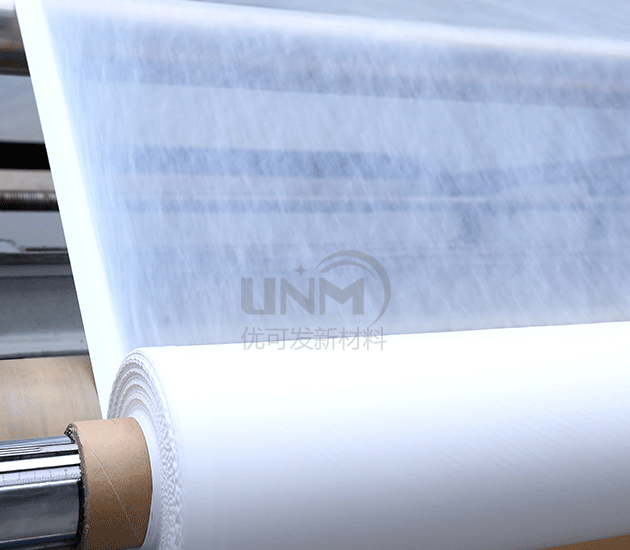

Teflon foam membrane has a fibrillar microporous structure and high porosity More than 88%, with 1.4 billion micropores per square centimeter, with a pore size range of 0.1μm-0.5μm. This film is coated on various fabrics and substrates with a special process, and can become a new filter material. The membrane has small pore size, Evenly distributed and with large porosity, it can filter all dust particles including bacteria while maintaining air circulation, achieving advanced purification and ventilation purposes.

It is a company specializing in R&D, production and sales of Teflon bubble point filmMaterial manufacturers. Our company is different from other manufacturers. Our company can according to the user’s requirements. By optimizing the combination of key technical parameters such as speed ratio, pressure ratio, and operating temperature, the air permeability, thickness, and void ratio can be adjusted online according to the ratio and pore-forming medium to meet your different requirements. Interested parties can enter the store for consultation.

</p