The places where air filters are used are generally divided into two categories. They “perform their duties” in their respective positions to create fresh air for people. Next, we will explain to you the application of air filters and H13 high-efficiency filter materials in living environments and industrial production.

1. Living environment

Nowadays, the air outside is getting worse and worse, and indoors are not immune to harmful substances. Formaldehyde, benzene and other harmful substances in indoor decoration materials, coupled with the use of chemical synthetic materials, adhesives, office or daily necessities and electrical appliances, are emitted indoors The increasing number of various organic volatiles, as well as air pollution caused by small bacteria, dust and smoking carried indoors by people, have been proven to cause a variety of symptoms and symptoms in relatively closed air-conditioned rooms. The spread of infectious diseases.

2. Industrial production

Industrial production mainly includes the pharmaceutical industry, and its air cleanliness is mainly It is to meet the requirements of products and product quality management. If the air quality does not meet the required cleanliness, medicines and articles will be contaminated, and substandard products will be produced. Therefore, in order to avoid this situation, it is necessary to actively cooperate with the use of air filter devices and H13 grade high-efficiency filtration materials materials, and adopt various corresponding measures in all relevant aspects such as air-conditioning air supply systems, building decoration and maintenance management. Only comprehensive measures can ensure the effectiveness of air purification.

However, depending on the type of products and items, the requirements for indoor cleanliness are also different. Some clean workshops, such as integrated circuit Panhang gyroscopes, etc. The assembly process of precision instruments is very sensitive to dust, and some spaces such as the pharmaceutical industry have cleanliness requirements that are close to those of ordinary living environments. In an environment with people, if the cleanliness requirements are lower than those for human habitation, then The requirements for human residence shall prevail.

Those processes with high cleanliness require the use of cleanliness and biological clean rooms according to its requirements. Various clean rooms also rely on corresponding air purification measures. One of the important ones is the supply of sufficient and purified clean air, so that the indoor air reaches the standard of clean air.

As a high-efficiency separation filter material design solution provider, we are committed to developing and manufacturing high-quality H13 grade high-efficiency filter materials and Composites to protect people, processes and systems. Our company provides comprehensive, innovative air filtration solutions designed to remove and control airborne particulate and gaseous contaminants in commercial, industrial, clean room and transportation applications.

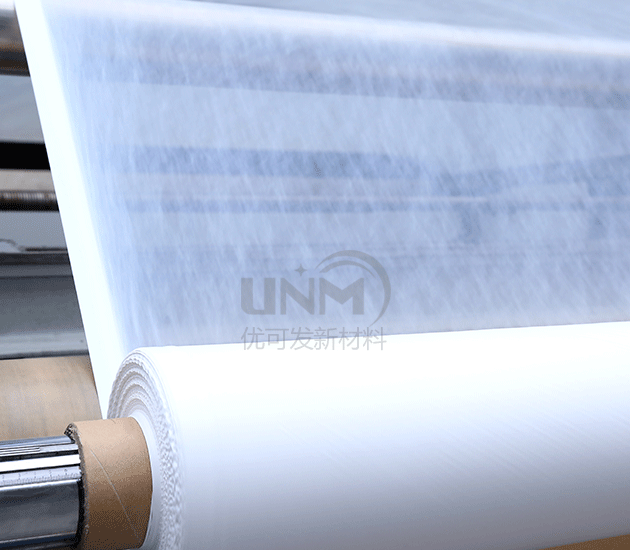

The high-efficiency filter paper obtained by thermally compounding the self-developed high-efficiency PTFE microporous film and imported non-woven fabric has a reliable filtration grade of H13-U16 and excellent wind resistance. Low energy consumption and low energy consumption, it is widely used in purification engineering systems.

The H13 high-efficiency filter materials produced by the manufacturer are all imported raw materials and have a full set of advanced production equipment. The advanced clean room and independent composite slitting workshop ensure the production quality of PTFE film; imported production testing instruments are used to test the quality of PTFE film, and it has passed international SGS testing and certification, and ISI testing and certification. Interested parties can enter the store and contact us.

</p