PTFE is a semi-crystalline polymer. Its crystals are composed of parallel-arranged folded chains to form lamellae, and then the lamellae are accumulated to form a ribbon-shaped polycrystalline polymer. The lamellae and lamellae are There is a sticky amorphous part in between. The interaction between Ptfe molecular chains is weak, and the activation energy of the ribbon structure to form fibers is only 11.3KJ/mol, which is only several times the ambient temperature. Therefore, the ribbon structure can easily be pulled out of particles and become microfibers under the action of external stress.

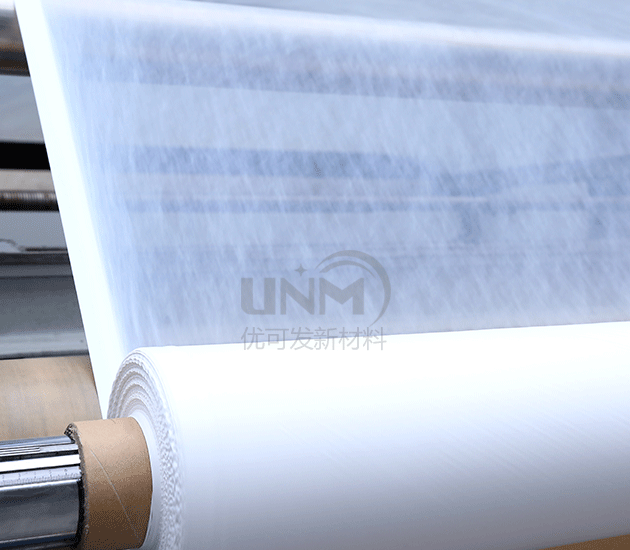

ptfe nanofilmThe density is very small, usually only 1.75g/m2 , it needs to be thermally compounded with non-woven fabric or ES hot air cotton to form a “PTFE film + non-woven fabric” double-layer composite film, or a “non-woven fabric + PTFE film + non-woven fabric” three-layer composite film.

PTFE nanofilm adopts special paste extrusion and biaxial stretching technology to produce fiber diameters below one hundred nanometers, and the fiber cross-sectional area is only that of PP melt Spraying 1% of the fibers, the network structure formed by the staggered arrangement of these nanofibers has very good filtration efficiency, which is enough to protect against small bacteria and viruses, and has the characteristics of high efficiency and low resistance.

ptfe nanofilm has small pore size (0.05~0.45μm), uniform distribution, and large porosity, while maintaining air circulation. Through physical screening, small bacteria and other bacteria are blocked on the surface of the mask, and with the help of the strong self-lubricating characteristics of the polytetrafluoroethylene material, each exhalation will reversely push back the particles attached to the surface of the mask. It can be placed in the environment repeatedly, without relying on electrostatic adsorption, and truly achieves a very good protective effect.

ptfe nano film has excellent media resistance and weather resistance. The microporous structure of ptfe microporous membrane is special – the fibers are distributed radially with the “nodes” as the center, and the different “nodes” are interlaced by micro-fibers, just like thousands of layers of screens with different meshes superimposed on each other. Together. Interested parties can enter the store and contact us.

</p