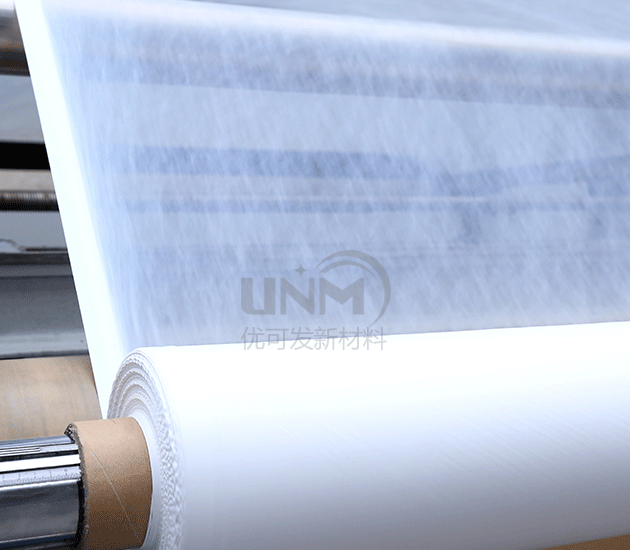

Polytetrafluoroethylene microporous membrane is a polymer compound polymerized from tetrafluoroethylene. It is prepared through a biaxial stretching process. Polytetrafluoroethylene Vinyl fluoride (ptfe) material has a microporous structure with staggered fibers. It has high porosity, small and uniform pore size, and high dust interception efficiency, which can reach more than 99.9995%. The material has properties such as temperature resistance, oxidation resistance, alkali resistance, and hydrophobicity. It is widely used in air purification, industrial dust removal, electronic appliances, clothing and so on.

Polytetrafluoroethylene microporous membrane forming process, known as Biaxial stretching, or stretching, is the most commonly used processing method. PTFE can be stretched at room temperature to 327°C, that is, the stretching below the melting point is performed in a high elastic state. Stretching at low temperatures will cause the film to rupture, making it impossible to stretch. When it is higher than 327°C, the crystalline state between PTFE molecules changes to amorphous, and the network structure can be obtained well. Therefore, the general stretching temperature is between 40°C and 40°C. between 327℃.

In production, the stretching temperature is related to the stretching rate and speed, and also depends on the strength and size of the product. At high temperature, PTFE microporous membrane is softer and easier to stretch, has good dimensional stability and is not easy to retract. However, if the temperature is too high, the strength of the product will be reduced, which may also lead to breakage. The greater the stretching rate, the higher the required temperature, because a lower stretching temperature requires a greater pulling force. When the pulling force exceeds the strength that the drawn product can withstand, it will break. On the contrary, the stretching rate is small, The temperature can be lower.

Differences in temperature also directly affect the performance indicators of the products. Therefore, it is necessary to find a range suitable for specific processes and equipment during production. The strength, pore size, and porosity of a product are important indicators that determine the quality of the product. For different products with different use environments and conditions, the corresponding production process is selected to produce suitable products with small pore size, uniform distribution, high porosity and Nodules small PTFE membrane.

Suzhou New Material Technology Co., Ltd. specializes in the production and sales of polytetrafluoroethylene microporous membrane and various types of membrane filter media products . Interested parties are welcome to enter the store for consultation.

</p