Protective clothing is a type of chemical protective clothing. It is mainly used by medical staff as work clothing that can effectively block microorganisms, prevent the penetration of body fluids, and prevent the infection of germs. The GB19082-2009 “Technical Requirements for Disposable Protective Clothing” promulgated by our country puts forward more detailed technical requirements forePTFEclothingfabrics, stipulating Protective clothing should have indicators such as flame retardant performance, water level, charge density, elongation at break and water repellency.

Looking at all current fiber fabrics, it is difficult to meet the water repellency and liquid barrier properties required by the standards, so it is inevitable to Fabrics are laminated or coated to improve their particle barrier properties. High-quality protective clothing can greatly improve the protective performance of medical staff and play a very good protective role against some highly infectious microorganisms and viruses, minimizing the harm.

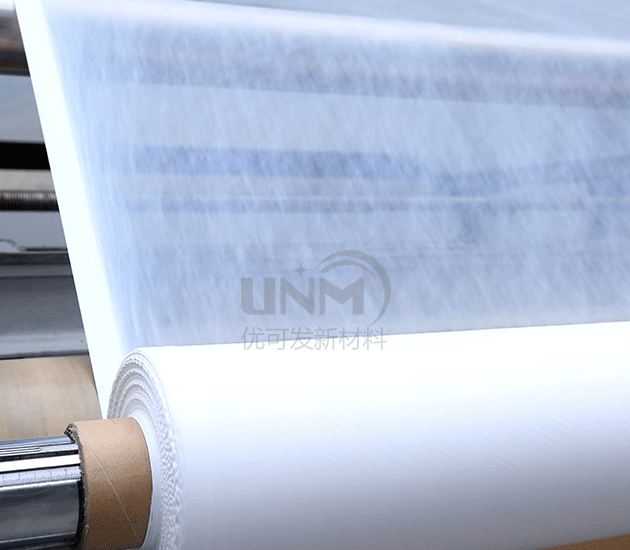

ePTFE clothing fabric has strong hydrophobicity, chemical resistance, water repellency and low wind resistance, and can obtain high The dust removal efficiency is very high. For some very small particles with a diameter of 0.1um-0.3um, the filtration level can reach H13-U16. In addition, the biaxially stretched film can undoubtedly achieve ultra-low emissions in intercepting various types of dust generated during the production process of the company, and all of them comply with current environmental protection standards.

ePTFEClothingFabric The PTFE materials produced are all imported raw materials. It has a full set of advanced production equipment, an advanced clean room and an independent composite slitting workshop to ensure the production quality of PTFE film; it uses imported production testing instruments to detect the quality of PTFE film, and also passes SGS Testing and certification, and ISI testing and certification. Interested parties can enter the store and contact us.

</p