There have been many systematic studies on protective fabrics and clothing abroad, and most of them currently useePTFEclothing fabrics and formulated corresponding standards according to different needs.

In China, protective clothing fabrics and clothing can be roughly divided into coating materials, PU|TPU film composite materials from the materials used. And three types of PTFE microporous membrane composite materials:

1. Coating material. Most domestic companies use wet or dry polyurethane, polyacrylate, and polyvinylidene fluoride to coat and finish fabrics, and then use the fabrics to make protective clothing.

2. PU, TPU film composite materials. This composite material has corresponding adjustments in moisture permeability and comfort compared with coated materials.

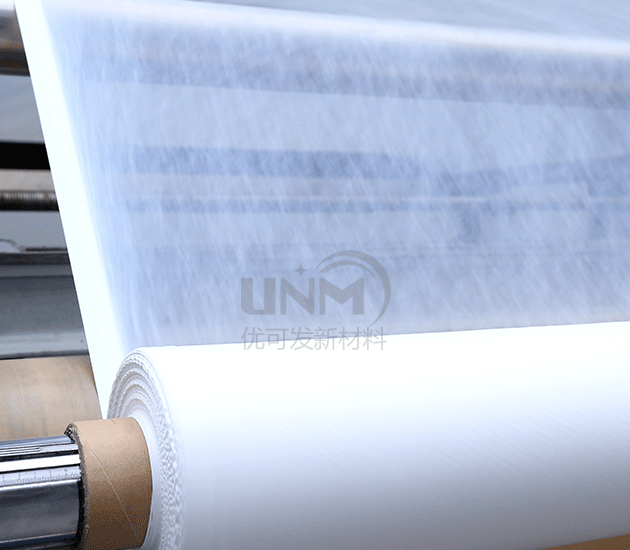

3. PTFE microporous membrane composite material. ePTFE clothing fabrics can well solve the two shortcomings of coating materials, PU, and TPU film composite materials such as poor long-term use and unsatisfactory moisture permeability.

The main characteristics of the PTFE protective clothing filter material produced as a protective clothing are that it is hydrophobic and breathable, and has good comfort. Its hydrophobic and breathable function is A layer of microporous film is compounded on the outer fabric of the garment. These micropores are evenly distributed, with small pore diameter and high porosity. The characteristic of this kind of fabric is that it has good stability and its performance is not easy to change even under low temperature conditions, soePTFEclothingfabricsare often used Used in a variety of harsher environments.

PTFE membrane technology has always been the core of the business and plays an indispensable role in many fields such as biopharmaceuticals, equipment, food and beverages, semiconductor manufacturing processes, and communications. Role, the pore-forming ability ranges from 0.1μm to 1μm, providing functional solutions such as fine filtration, removal of small bacteria and viruses, water repellency, breathability, and sound transmission. Interested parties can enter the store for consultation and purchase!

</p