When companies select filters, they often only consider the material, specifications and models of the filter. Process parameters such as filter pressure difference range, temperature range, and filter flow rate conditions are Follow the filter instructions. In fact, enterprises should determine the filtration process parameters based on the properties of the media to be filtered and process requirements, and confirm the range of process parameters.

As the requirements for microbial filtration technology continue to increase, ASTM is used to define bacterial filtration membranes The F838 industry standard measurement method came into being, and this standard measurement method is still in use today. Not all processes require the true removal of bacteria. For biopharmaceutical processes, it is possible that only the bioreactor feeding process and filling process require the use of ultra-precise grade filtration products, and the requirements for capacity are quite strict.

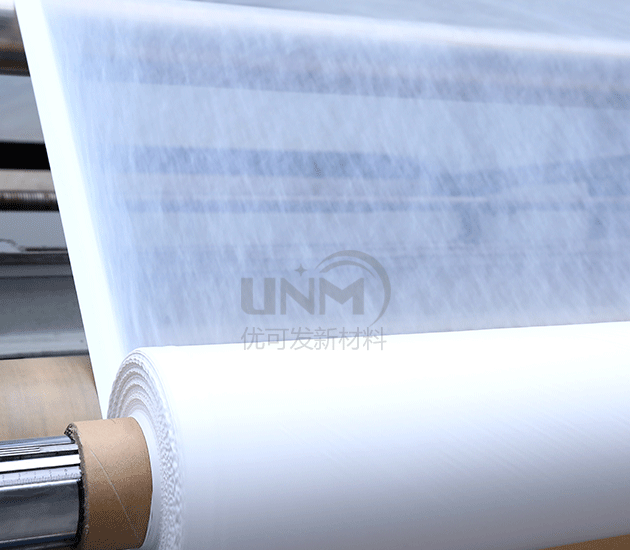

The independently developed and produced bacterial filtration membrane has a porosity of 80%~90%, and has undergone high-temperature heat setting treatment to make it microporous. The structure is stable and can intercept dust particles very well. Moreover, its pore size is small and uniform, and its surface filtration mechanism makes it easy to remove dust. It has strong hydrophobicity and low surface energy, which can ensure that all impurities such as small bacteria are intercepted, and it has a large flux. When used for gas filtration, it can intercept all kinds of phages, small bacteria and particles above 0.02um.

Bacterial filtration membrane technology has always been the core of the business, with pore making capabilities from 0.1μm to 1μm, providing fine filtration, Functional solutions such as removing small bacteria and viruses, hydrophobic, breathable, and sound-permeable. The manufacturer has a full set of advanced production equipment and technology, as well as an advanced clean room and an independent composite slitting workshop to ensure the production quality of Bacterial Filtration Membrane; the product materials produced are all imported raw materials. High uniformity, stable performance and good breathability. Interested parties can enter the store for consultation and purchase!

</p