EPTFE membrane is a membrane with high porosity, high permeability and high chemical stability, which is made of special ePTFE fiber as raw material and using complex processes such as high temperature and high pressure. Material. The following is the production process of eptfe film manufacturer:

1. Raw material preparation: It is necessary to ensure that the selected ePTFE The fiber quality is excellent, with uniform dispersion and fine fiber diameter. These properties can be guaranteed through precision processing through fiber drawing, sintering and other processes.

2. Fiber processing: During the production process, the ePTFE fiber needs to be processed, including stretching, hot pressing, rolling and other steps, in order to make the fiber They are compressed and connected with each other to form a porous structure.

3. Composite bonding: After overlapping and arranging the processed fibers according to rules, composite bonding is performed under high temperature and high pressure to make them firmly connected. together and form the desired film structure.

4. Calendering and extrusion: eptfe film manufacturer extrudes and calenders the film through an extruder to make its surface smooth and No defects, and parameters such as film thickness and pore size are appropriately adjusted.

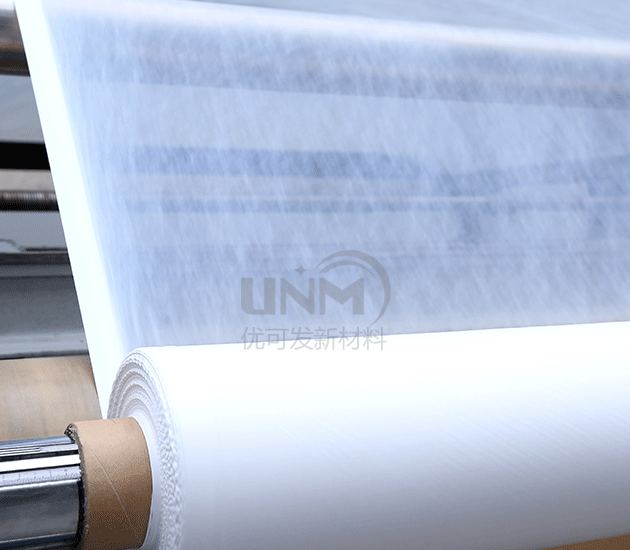

5. Post-processing: Clean the EPTFE film and shape it by rolling or cutting to achieve the required shape and size. ; At the same time, strict quality inspection and testing are also required for each batch of products to ensure that each product meets the specification requirements.

6. Packaging and shipping: After that, the inspected and tested EPTFE film is packaged and ready to be shipped to the customer. During transportation and storage, it is necessary to pay attention to moisture-proof, dust-proof and other measures to ensure that product quality and performance are not affected.

In short, eptfe membrane manufacturers need to have advanced production equipment and strong technical strength, and adopt a complete production process to Guarantee product quality and performance. During the production process, eptfe membrane manufacturers need to pay close attention to various parameters and indicators and make timely adjustments and optimizations. Only in this way can we produce high-quality, high-performance EPTFE membrane products to meet the needs and application requirements of different customers. Interested parties are welcome to enter the store and contact us.

</p