Non-woven fabric (English name: Non Woven Fabric or Nonwoven cloth), also known as non-woven fabric, is composed of directional or random fibers. It is called cloth because it has the appearance and certain properties of cloth.

To put it simply: it is not intertwined and braided together by yarns one by one, but the fibers are directly bonded together through physical or chemical methods, so when you When you get the sticky scale in your clothes, you will find that you cannot pull out the threads one by one.

1. Characteristics of non-woven fabrics

Non-woven fabrics have no warp and weft lines. They are very convenient for cutting and sewing. They are also light and easy to shape. Nonwoven fabrics break through traditional textile principles and have the characteristics of short process flow, fast production rate, high output, low cost, wide range of uses, and multiple sources of raw materials.

Less strength and durability compared to woven fabrics, and cannot be washed like other fabrics. Because the fibers are arranged in a certain direction, it is easy to split at right angles, etc. Therefore, the improvement of production methods is mainly focused on improving the prevention of splitting.

2. Classification of non-woven fabrics

Non-woven fabrics can be divided into:

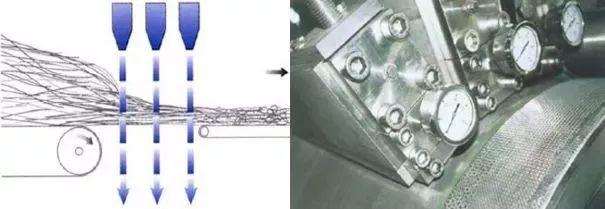

◆Spunlace non-woven fabrics

It is a high-pressure Fine water jets are sprayed onto one or more layers of fiber mesh to entangle the fibers with each other, thereby strengthening the fiber mesh and giving it a certain strength.

Features:

1. Flexible entanglement, does not affect the original characteristics of the fiber, and does not damage the fiber.

2. The appearance is closer to traditional textiles.

3. High strength and low fluff.

4. High hygroscopicity and rapid moisture absorption.

5. It feels soft and has good drape.

6. The appearance is varied.

7. The production process is long and covers a large area.

8. The equipment is complex, consumes a lot of energy, and requires high water quality.

Product applications: medical curtains, surgical gowns, surgical drapes, medical dressing materials, wound dressings, medical gauze, aviation wipes, clothing lining base fabrics, coated base fabrics, high-grade wipes for the electronics industry, cotton pads , wet wipes, mask covering materials, etc.

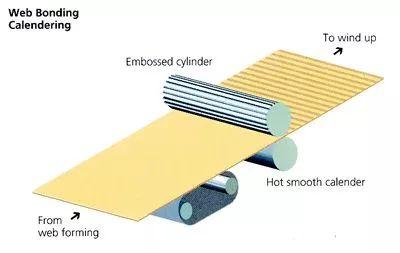

◆Heat-sealed non-woven fabric

It refers to adding fibrous or powdery hot-melt adhesive reinforcement materials to the fiber web, and then the fiber web is heated, melted and cooled to strengthen it into a cloth.

Features:

The surface of surface-bonded hot-rolled products is relatively smooth, while the surface of point-bonded hot-rolled products is relatively fluffy.

Product application: production of covering materials for baby diapers and women’s sanitary napkins, ointment base fabrics, clothing linings, masks, etc.

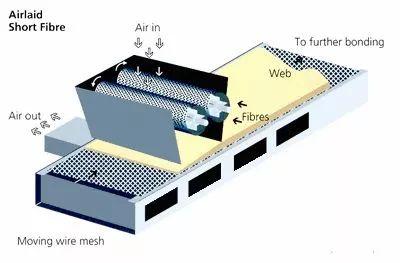

◆Pulp air-laid non-woven fabric

It can also be called dust-free paper and dry paper-making non-woven fabric. It uses air-laid technology to open the wood pulp fiberboard into a single fiber state, and then uses the air-laid method to agglomerate the fibers on the web curtain, and then strengthen the fiber web to form cloth.

Features: good fluffiness, soft hand feel, and super hygroscopicity.

Product application: medical and sanitary materials, especially highly absorbent disposable sanitary products (such as diapers, sanitary napkins, wet wipes, wipes, etc.).

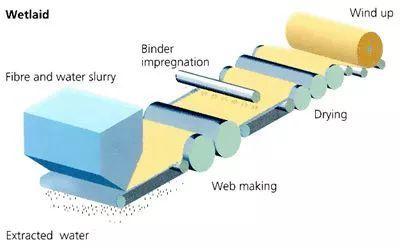

◆Wet-laid non-woven fabrics

The fiber raw materials placed in the water medium are opened into single fibers, and different fiber raw materials are mixed at the same time to form a fiber suspension slurry. The slurry is transported to the web-forming mechanism, and the fibers are formed into a web in a wet state and then reinforced into cloth.

Features:

1. High production speed, which can reach 400m/min.

2. Short fibers can be fully utilized.

3. The product fiber web has good uniformity.

4. Large water consumption and high one-time investment.

Product applications:

1. Special paper: dust/liquid filter paper, tea bags.

2. Industrial use: filters, insulation materials, sound-absorbing materials.

3. Medical use: medical backing, medical tape, surgical bag wrapping material.

4. Civilian use: wallpaper, etc.

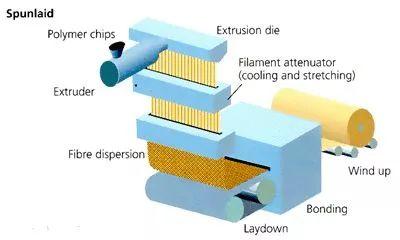

◆Spunbond non-woven fabric

After the polymer has been extruded and stretched to form continuous filaments, the filaments are laid into a web, and the web is then bonded to itself. Bonding, thermal bonding, chemical bonding or mechanical reinforcement methods turn the fiber web into a non-woven fabric.

Features:

1. The fiber web is composed of continuous filaments.

2. Excellent tensile strength.

3. There are many process changes and various methods of reinforcement can be used.

4. The filament fineness changes in a wide range.

Product applications:

1. Polypropylene (PP): geotextile, tufted carpet base fabric, coated base fabric, medical and health materials, coating of disposable products Materials etc.

2. Polyester (PET): filter materials, lining materials, tufted carpet base fabrics, agricultural materials, packaging materials, etc.

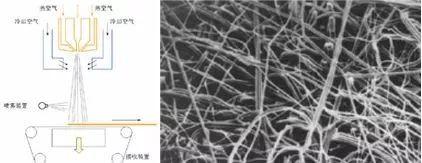

◆Melt-blown non-woven fabric

Melt-blownThe process of non-woven fabrics: polymer feeding—melt extrusion—fiber formation—fiber cooling—web formation—reinforcement into cloth.

Features:

1. The fiber web is composed of extremely fine shorter fibers.

2. The fiber web has good uniformity and soft hand feel.

3. Good filtration performance and liquid absorption performance.

4. The fiber web has poor strength.

Product applications: filter materials, medical and sanitary materials, clothing materials, battery separator materials, wiping materials.

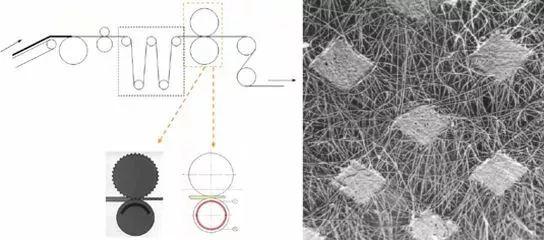

◆Needle-punched non-woven fabric

It is a type of dry-laid non-woven fabric. Needle-punched non-woven fabric uses the puncture effect of needles to reinforce the fluffy fiber web into cloth. .

Features:

1. Flexible entanglement between fibers, with good dimensional stability and elasticity.

2. Good permeability and filtration performance.

3. Feel plump and fluffy.

4. Various collective patterns or three-dimensional molding products can be manufactured according to requirements.