Everyone, have you been flooded with various shutdown notices recently?

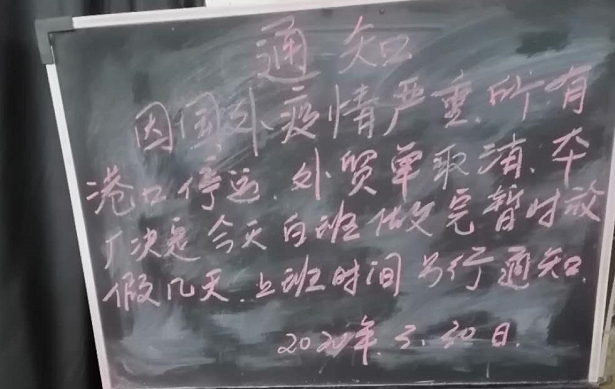

Due to foreign The epidemic is serious, ports have been suspended, and foreign trade orders have been cancelled. After today’s day shift, we will have a few days off. Working hours will be notified later.

Shaoxing textile companies are in urgent need of cash flow

The boss of a foreign trade company in Keqiao, Shaoxing, said that the impact of the overseas epidemic has been fatal. European factory orders have decreased, inventories are backlogged, and half of the payment may not be recovered. The cash flow of many factories cannot last three months.

In the first two months of this year, China’s total export value of goods trade was 2.04 trillion yuan, a decrease of 15.9% compared with the same period last year. . As the international epidemic further spreads, the foreign trade import and export situation may further deteriorate, and it is necessary to prepare for early response. “Xin Guobin, Vice Minister of the Ministry of Industry and Information Technology, said at the press conference of the Joint Prevention and Control Mechanism of the State Council held on March 30.

2 On March 22, workers at a foreign trade company in Shaanxi were doing sorting work. Source: “Shaanxi Daily”

The garment foreign trade industry is one of the hardest-hit areas under the impact of the epidemic. Information It shows that many well-known fast-selling clothing brands such as ZARA and HM are gathered in Europe and the United States. Affected by the new crown epidemic, the above-mentioned companies have adopted measures such as large-scale store closures around the world, and their sales have been affected.

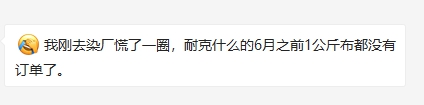

Trade orders are cancelled, and the printing and dyeing process is under pressure

Currently, Mr. Chen, a trader, said that he went to the dyeing factory and found that there were no orders from a certain sports brand before June. In previous years, he would more or less receive printing and dyeing of knitted fabrics from this brand. Order. “I feel a little panic now. I still have 70,000 meters of orders on hand that I am rushing to make. I should be able to ship them in the next few days, but I don’t know where to find the next orders. I don’t even dare to place some orders now.” catch. “Mr. Chen said.

It is reported that the current order cancellations on the fabric trade side have been gradually transferred to weaving factories and printing and dyeing factories. A salesperson from a printing and dyeing factory said that orders There are quite a few orders that were temporarily stopped or were quickly stopped after being brought in, accounting for about 30% of the total orders. “Currently, the work in the dyeing factory is less than before, and orders are expected to decrease one after another. ”

Countless factories around the world have suspended production due to the ongoing epidemic. Recently, the United States announced that epidemic prevention measures will be extended until April 30, and Spain has suspended all non-essential production work. At the same time, chemical giants BASF has reported 4 new confirmed cases among employees, and U.S. factories will reduce production by 47% of contracted work. Countless factories around the world have suspended production and announced that all orders will be suspended or canceled. The global economy is stagnant due to the epidemic.

Spain, the fifth largest chemical producer in Europe, announced the suspension of non-essential production work

On the 29th, the Spanish government ordered that from March 30 to April 9, all non-essential production work would be suspended. All non-essential production work.

According to our understanding, Spain is the “European Motor Vehicle Production Center”, and most of the motor vehicles and auto parts produced in this region are Exported overseas.

In addition, Spain is the fifth largest producer of chemical products in Europe, accounting for 2% of the world’s turnover. There are more than 3,000 companies in the chemical industry, with an annual turnover Nearly 48 billion euros, accounting for 10% of the gross national product. This industry has more than 500,000 direct, indirect and derived jobs.

Key enterprises include: Repp REPSOL, GAS NATURAL FENOSA, CEPSA.

BASF With four newly confirmed cases, the U.S. factory will cut production by nearly half

On March 25, a BASF spokesperson revealed that two employees and two contractors working at BASF’s Geismar factory had tested positive for COVID-19. So far, BASF’s global A total of 5 people have been diagnosed. Currently, more than 45% of BASF employees are working from home, and the Geismar factory has reduced 47% of contract work.

Affected by the outbreak of the new coronavirus pneumonia, BASF has already Short-time working introduced at German plants in Münster/Hittrup and Würzburg. Weak automotive market combined with coronavirus impactThe impact has affected the product output of chemical companies, including coatings, plastics, man-made fibers and additives. This is the fundamental reason why BASF shortened working hours and reduced output.

In addition, the MDI device project of the Geismar plant in Louisiana, which is being expanded with an investment of US$87 million, may be affected.

Many overseas brand factories have stopped production and orders have been stagnated or canceled

Suffering from mainland China The double whammy of shutdowns and shutdowns caused by a global pandemic. Currently, many brands have ceased production, suspended sales, and canceled or postponed events around the world.

The Italian luxury brand Gucci has closed 6 factories and all stores in Italy. With Italy still under nationwide lockdown, Gucci is expected to continue closing factories for some time. Gucci’s order volume for handbags in February was halved compared to January, and there is likely to be zero orders in March.

The French brand Hermes has decided to close all 42 factories until March 30, including tanneries, clothing factories, leather goods factories and porcelain factories. Its perfume factory is producing handwashing fluid.

French luxury brand Chanel announced the suspension of production on March 18. Chanel said in a statement that in accordance with the instructions of the French government, it will temporarily close all factories in France, Switzerland and Italy and stop the production of high-end fashion, ready-to-wear, high-end jewelry and jewelry.

Louis Vuitton (LVMH), the world’s largest luxury goods group, said it is currently trying its best to maintain operations, but its suppliers revealed that orders for LV handbags have dropped by 30%.

Fashion brands such as Urban Outfitters, Nike, and Supreme in the United States, as well as Lululemon in Canada, have also closed their stores.

At the same time, many overseas market orders received by domestic companies have completely stagnated, either canceled or suspended.

Primark, the largest fashion retailer in the UK, cancels all orders

According to news on March 22, the famous British affordable fashion chain Primark All orders from suppliers that have not yet been delivered have been cancelled. They have force majeure clauses in their contracts and rely on force majeure clauses to cancel orders. Primark has 40% of its products from China and is also the largest fashion retailer in the UK market.

Top Shop parent company Arcadia Group freezes payments to suppliers

Fashion retail group Arcadia Group has announced the temporary closure of all stores in the UK and Ireland and has frozen payments to suppliers.

Peacocks cancels all orders before June 20

The British family fashion brand Peacocks said it will cancel all future orders for the spring of 2020. Completed order. For goods received after March 16, Peacocks offers three options to suppliers: one is to wait until all inventory is sold before paying; the other is to pay at a 50% discount; and the third is to return the goods.

Many orders from factories have been cancelled, and the foreign trade industry is completely in the cold winter. No matter whether orders are canceled or reduced, life for these companies is relatively difficult. Most of them are labor-intensive industries. Now there is a general trend to reduce labor costs. Many companies are forced to take “holidays” in order to reduce operating costs. As for when the holiday will last, it may be two to three months or longer. It all depends on the effectiveness of global epidemic prevention and control and the degree of economic recovery.

President of Ningbo Ruifu Industrial Group Co., Ltd.: Work will officially resume from February 10th, and customers will continue to urge us. We arrange shipment orders and production capacity. In fact, we have been canceling and delaying orders one after another since last week.

Deputy General Manager of Ningbo Huafu Import and Export Co., Ltd.: Some of our goods are even in the shipping stage, and some of them may even be arriving at the port soon. Some countries have said they are going to close down the country, and there is no way to pick up those goods. So the entire supply chain has a huge impact on us.

Director of the Shenzhen Factory of Songteng Industrial Co., Ltd.: The Canton Fair in April has been suspended. The biggest source of the Canton Fair is export orders. My business has been suspended, which is certain for the company. will be greatly affected.

On March 18, Panduit Toys, a large toy manufacturer with more than 1,200 employees, announced its closure due to cancellation of orders in Europe and the United States.

On March 21, Jiahe Electronics, a well-known brand Cosonic headphone manufacturer with 4,000 employees, announced that all workers would cut their wages or quit the factory due to the epidemic.

On March 21, a large manufacturing company in Dongguan had to declare a three-month holiday because its largest customer, FOSSIL of the United States, canceled all orders. The future is worrying.

A certain factory even announced that it would suspend all orders due to customers and announced that it would continue to be closed until August 1st.

Raw material prices have plummeted

At present, the entire raw material market prices are in a depression. On the one hand, raw material prices on the supply side have dropped sharply due to the continuous plummeting of crude oil. On the other hand, demand has been weak and manufacturers have difficulty in consuming existing inventories. Under dual pressures, this has continued to cause a downward trend in the raw material market.

Last week, among the 64 important chemical products, 56 products fell, accounting for 87.5%, and only 3 products increased, accounting for 4.69%. Five products remained unchanged, accounting for 7.81%. The top three products with the largest decreases were pure benzene (↓22.78%), toluene (↓14.67%), and sec-butyl acetate (↓14.58%). The three products that increased were isopropyl alcohol (↑5.13%), propylene (↑3.52%), and glycerin (↑2.94%).

▽Chemical price decline list

The price focus of polyester filament It has continued to decline and has reached a low in recent years, with product prices falling close to 25%–35%.

review-src=”” data-preview-group=”1″ src=”https://www.tradetextile.com/wp-content/uploads/2023/jdli4c3vc02.jpg”>

Last week, among the 64 important chemical products, 56 products fell, accounting for 87.5%, only 3 products increased, accounting for 4.69%, and 5 products remained unchanged, accounting for 7.81%, with a decrease of The top three products are pure benzene (↓22.78%), toluene (↓14.67%), and sec-butyl acetate (↓14.58%). The three products that increased were isopropyl alcohol (↑5.13%), propylene (↑3.52%), and glycerin (↑2.94%).

▽Chemical price decline list

The price focus of polyester filament It has continued to decline and has reached a low in recent years, with product prices falling close to 25%–35%.

</p