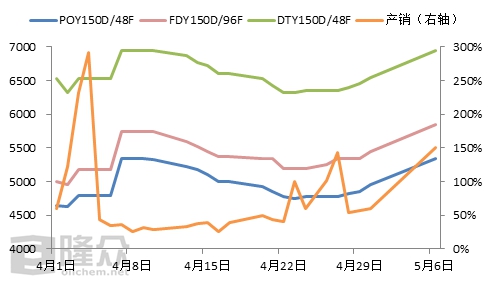

After intensive downstream stocking in early April, the polyester filament market gradually became deserted. As can be seen from the figure below, the production and sales of polyester filament remained at 30-50% for a long period from the beginning of April to the end of the month. However, at the end of the month, the demand for protective clothing increased. The sales of pongee and polyester taffeta are booming, and the corresponding polyester filament production and sales are picking up.

As the May Day holiday approaches, the market enthusiasm subsides. Some industry players believe that during the May Day holiday, downstream texturing and weaving companies plan to stop for the holiday, and the demand for protective clothing is limited, and the market will be hot after a short period of time. Calm will gradually return, and it is expected that the market may have low price promotions during the May Day holiday. However, after protective clothing, body bags once again detonated the polyester filament market.

Comparison of prices and production and sales data changes of mainstream polyester filament models from April 2020 to the present

The market production and sales were relatively stable in the three days before the May Day holiday, and most companies were on the sidelines. However, due to the continued rebound in oil prices, coupled with the equipment accident at the Ningbo raw material factory before the holiday, boosted by multiple good news, in the second half of the holiday, The demand for polyester yarns has picked up, and factories have taken advantage of the trend to raise prices. The volume and price of polyester filament yarns have both risen. At the end of the holiday, downstream wait-and-see sentiment has gradually increased, and market production and sales have fallen rapidly. However, oil prices have continued to rise. With the support of the cost side, polyester filament companies have continued to rise. , and the increase was slightly higher than that of the previous period. Driven by the rising buying sentiment, some polyester yarn production and sales increased. However, with the drop in oil prices and yesterday’s large increase causing downstream resistance, the polyester market is running steadily today.

As mentioned above, in the early stage, boosted by the demand for protective clothing, FDY production and sales recovered. However, the demand for protective clothing was limited, and the market atmosphere gradually became deserted after downstream centralized procurement. The current increase in orders for body bags has once again driven the polyester market. According to the person in charge of a funeral supplies company, the export volume of body bags in the past year was about 100,000, but in the past two months, they have been receiving inquiries for large orders of 3 million, 5 million, or even 10 million.

There are many materials for body bags on the market, such as Oxford cloth, pongee, non-woven fabric, nylon cloth, PVC waterproof cloth, OPP, PVA, LLDP, etc. Oxford cloth Polyester materials such as polyester and polyester polyester generally use DTY, and some of them can also be replaced by FDY. They are used in specific areas. The demand is very limited, sales are difficult, and the production cycle is also long. Therefore, the production company has to deal with the implementation of large orders. Doubtful.

Quoting data from Alibaba International Station, the number of orders for funeral supplies on the platform in March increased by 487% compared with February; from March 20 to April 20, inquiries about body bags The volume increased by 22,100% month-on-month; the top three places for funeral supplies traffic were the United States, Mexico and Italy, with the United States far exceeding other countries. Currently, the cumulative number of confirmed cases in the United States exceeds one million. In order to meet the rising demand, manufacturers in other industries are also replacing new equipment and will soon switch to the production of funeral supplies. There is no sign of recovery in the demand for conventional fabrics, and the demand for materials required for public health prevention and control is relatively short-lived.

For weaving companies, pongee, polyester taffeta, and Oxford fabrics are relatively popular conventional fabrics. The short-term increase in demand cannot drive the sales of other fabrics, while conventional fabrics The entry threshold for fabrics is low. Once companies follow the production trend, it will easily lead to oversupply and the company will enter the stage of accumulated inventory. Affected by the current public health incident, masks were popular in the first half, midfield protective clothing appeared, and body bags were popular in the second half. However, there were no new orders for regular clothing and home textiles. It is reported that summer orders for some foreign brands have shrunk by 70% compared with the same period in the same period. The market in May is difficult to say optimistic.

At present, some areas in Europe and the United States have gradually begun to resume work, but the number of new people is still increasing. According to the latest statistics, the cumulative number of confirmed cases worldwide exceeds 3.68 million, and the cumulative number of confirmed cases in the United States exceeds 1.24 million. . Among them, the risk of cluster infections is still rising. More than 42,000 medical staff in Spain have been infected. The cumulative number of confirmed cases in India’s largest slum is approaching 600 and still rising. Some experts warned that the current situation in the United States is still quite serious, and the hospital medical system is still overloaded. As the scope of testing continues to expand, the shortage of protective equipment in the United States will only become more serious. At present, some Southeast Asian countries have announced the extension of the ban, and the global crisis has not yet been resolved. It is difficult for terminal demand to see a substantial increase in the short term. </p