The factors that affect fiber moisture regain include internal factors and external factors, and external factors also work through internal factors. The intrinsic factors of the fiber include the number of hydrophilic groups of the fiber macromolecules and the strength of the hydrophilicity, the crystallinity of the fiber, the size and number of pores in the fiber, the specific surface area of the fiber, and the nature and content of fiber companions. They are It has an impact on the moisture regain of the fiber. The ability of the fiber to absorb moisture in the air is mainly determined by its internal factors. However, external factors such as ambient air conditions, length of placement time, and moisture absorption and release processes are also external factors that cannot be ignored for a specific fiber.

Intrinsic factors affecting the moisture regain of textile fibers

1. The role of hydrophilic groups

In fiber macromolecules, the number of hydrophilic groups and the polarity of the hydrophilic groups can affect its moisture absorption capacity. For example, hydroxyl group (-OH), amide group (-CONH), amine group (-NH2), carboxyl group (-COOH), etc. are all strong hydrophilic groups. They have a great affinity with water and can interact with water molecules. Chemically bound water (or absorbed water) is formed. The more such groups, the higher the moisture absorption capacity of the fiber.

Figure 1 Chemical formula of amide group

Cellulose fibers, such as cotton, viscose fiber, cupro fiber, etc., macromolecules Each glucose residue group in it contains 3 hydroxyl groups, so it is highly hygroscopic. Most of the hydroxyl groups in acetate fiber are replaced by acetyl groups, and the acetyl group (-COCH3) is not very attractive to water, so the hygroscopicity of acetate fiber is low.

The main chain of protein fiber contains hydrophilic amide group (-CONH), and the side chain contains hydroxyl group (-OH), amine group (-NH2), carboxyl group ( -COOH) and other hydrophilic groups, so it has good hygroscopicity, especially wool, which has more hydrophilic groups in the side chain than silk, so its hygroscopicity is better than silk.

Synthetic fibers contain few hydrophilic groups, so their hygroscopicity is poor. Vinyl molecules contain carboxyl groups (-COOH), but after acetalization, part of the hydroxyl groups are blocked, so their hygroscopicity is reduced. Small, but its moisture absorption capacity is relatively good among synthetic fibers; the macromolecules of nylon 6 and nylon 66 contain an amide group (-CONH) on every 6 carbon atoms, so they also have a certain moisture absorption capacity; acrylic macromolecules There is only a weakly hydrophilic group cyano (-CN) in it, so its hygroscopic capacity is small; polyester and polypropylene lack hydrophilic groups, so their hygroscopic capacity is extremely poor, especially polypropylene, which basically does not absorb moisture.

2. Crystallinity of fibers

Fibers can be tightly gathered in the crystallization zone At this time, because the active groups form cross-bonds between molecules, such as hydrogen bonds, salt bonds, disulfide bonds, etc., it is difficult for water molecules to penetrate. If hygroscopicity is to occur, these must be opened. Cross-bonding is obviously difficult, so the hygroscopic effect of the fiber occurs mainly in the amorphous zone.

In the molecular structure of the fiber, the percentage of amorphous regions is closely related to the hygroscopic performance. The lower the crystallinity of the fiber, the stronger the moisture absorption capacity. For example, cotton and viscose fibers have three hydroxyl groups on each glucose residue. However, since the crystallinity of cotton fiber is about 70%, while the crystallinity of viscose fiber is only about 30%, the moisture absorption capacity of viscose fiber is very low. Much higher than cotton fiber.

3. Specific surface area and internal voids of fibers

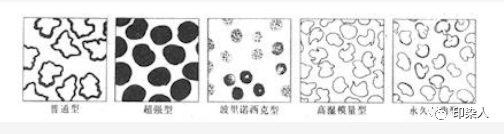

Figure 2 Cross-sectional view of viscose fiber

The larger the specific surface of the fiber, the more surface energy, the stronger the surface adsorption capacity, the more water molecules adsorbed on the fiber surface, and the better the hygroscopicity. . Therefore, the moisture regain of fine fibers is larger than that of coarse fibers.

The more pores in the fiber, the easier it is for water molecules to enter, and the capillary condensation water can increase, making the fiber more hygroscopic. The structure of viscose fiber is looser than cotton fiber, and the moisture absorption capacity of viscose fiber is higher than that of cotton fiber; the structure of synthetic fiber is generally denser; while there are micro gaps in the natural fiber tissue, the moisture absorption capacity of natural fiber is much greater than that of synthetic fiber.

4. Accompanying organisms and impurities in the fiber

Various accompanying impurities in the fiber have an impact on the moisture absorption capacity.

In addition. During the collection and preliminary processing of natural fibers, a certain amount of impurities will always remain, and these impurities often have high moisture absorption capabilities. Therefore, factors such as the amount of impurities in the fiber also have a certain impact on the moisture regain.

External factors affecting the moisture regain of textile fibers

1. The influence of relative humidity

Under certain temperature conditions, the higher the relative humidity, the greater the partial pressure of water vapor in the air, the greater the number of water molecules in unit volume of air, and the chance of water molecules reaching the surface of the fiber.The strength of plain fiber increases with the increase in moisture regain. The elongation at break of all fibers increases with the increase in moisture regain. The changes in strength and elongation of several common fibers in the wet state are shown in Table 1. As the moisture regain rate increases, the plastic deformation of the fiber increases and becomes soft and easy to deform. The surface friction coefficient of the fiber becomes larger as the moisture regain rate increases.

5. Effect on thermal properties

Water molecules in the air are attracted by the polar groups of fiber macromolecules And combined with it, the kinetic energy of the molecules is reduced, which is inevitably accompanied by the conversion of energy and is released in the form of heat. The heat released by fibers absorbing 1g of water at a given moisture regain is called hygroscopic differential heat, and the unit is J/g of water. The hygroscopic differential heat of various dry fibers is roughly similar, about 837~1256J/g water.

At a certain temperature, the total heat released by an absolutely dry fiber weighing 1g from the beginning of moisture absorption to complete wetting is called the integrated heat of moisture absorption, and the unit is J/g dry fiber. Fibers with strong moisture absorption capacity also have large moisture absorption integrated heat. The integrated heat of moisture absorption of common fibers is shown in Table 2.

The rate of moisture absorption and release of textile fibers and the amount of moisture absorption and release have an impact on the comfort of clothing. When dry fibers are exposed to an atmosphere with a certain relative humidity, they will absorb water vapor and release heat. This will increase the pressure of water vapor in the fiber and the temperature of the fiber itself, and slow down the moisture absorption rate. Fibers with high moisture regain need to absorb heat when releasing moisture, which reduces the water vapor pressure in the fiber and the temperature of the fiber itself, thereby reducing the moisture release rate. This is like adding a protective damping mechanism when the climate suddenly changes, which is beneficial to human body’s physiological temperature regulation, and moisture absorption and heat release are beneficial to the warmth retention of clothing. However, this characteristic is unfavorable for the storage of fiber materials. If the air is humid and the ventilation is poor during storage, it will cause the fibers to absorb moisture and release heat, causing mildew and even fires.

6. Effect on electrical properties

The special molecular structure of the polymer gives the fiber high electrical insulation properties. Its volume specific resistance is on the order of 109~1014. The companions of natural fiber often make its insulation worse. The extremely small amount of impurities and water in it are conductive. Therefore, after the fiber absorbs water, the insulation performance decreases, the dielectric coefficient increases, and the dielectric loss factor increases. Textile fibers Because of its insulating properties, it can be used as an insulating material.

However, this high insulation will produce static electricity due to the friction between fibers or other parts during textile processing, destroying the normal movement of fibers and affecting the textile process. Fiber processing proceeds normally. Cleaned wool and chemical fibers have such problems in textile fiber processing. The increase in the moisture regain of the fiber can greatly reduce the resistance of the fiber. For example, the volume specific resistance of wool is about 1013Ω·cm when the relative humidity is 10%, and the volume specific resistance drops below 107Ω·cm when the relative humidity is 90%. .

Production practice shows that if the volume specific resistance is below 109Ω·cm, textile processing will be smoother. Therefore, it is very important to control temperature and humidity during the production process. But for antistatic, other effective methods need to be taken. Changes in fiber moisture regain cause changes in resistance and dielectric coefficient. According to this principle, fiber moisture regain can be measured indirectly. Resistive and capacitive moisture meters are designed using this principle.

7. Effect on optical properties

Among the optical properties of fiber, the refractive index is closely related to the moisture regain. As the moisture regain of the fiber increases, the optical refractive index of the fiber decreases. This is also caused by water molecules entering the fiber, causing certain changes in the molecular structure.

In summary, the hygroscopicity of fiber is related to the appearance of the fiber and various physical properties. For example, different moisture content, not only weight Differences occur, and the various properties of the fibers also change greatly. It can be seen that moisture absorption is one of the most important properties of textile fiber materials. Therefore, when testing various properties of fibers and their products, this factor must be considered and tested under uniformly specified standard conditions. If in actual work, due to conditional constraints or in order to quickly obtain test results, it cannot be carried out under the standard state, the temperature and humidity conditions at that time must be noted, and necessary corrections must be made if possible. </p