At the beginning of 2020, a new type of coronavirus spread from Wuhan quietly sneaked into people’s lives. Hubei fell, Zhejiang fell, Jiangsu fell… and then faced quarantine! Road closure! It is difficult for companies to start operations, workers cannot go to work, and orders are facing delays. 2019, which was already a bad year, is now even worse.

Cannot start work, even year-end orders have been cancelled

The new coronavirus is coming fiercely, workers cannot be in place, and factories are delayed in starting operations. It has been pushed back and pushed again, and some areas have even suspended work indefinitely. There is no precise time. According to a manager of a company that produces imitation silk, customers canceled more than 300,000 meters of orders in the past two days. If things continue like this, several orders signed at the end of last year will probably be cancelled. In some cases, the raw materials are already ready and production can be completed just waiting for the workers to arrive. Now we don’t know when work will be resumed. However, the current epidemic situation is not very optimistic. Not to mention those customers who are in a hurry to receive goods, even customers who are not in a hurry may also cancel orders due to concerns about logistics, production, and the low shipment rate of dyeing factories after the start of work. Indeed, The impact of the epidemic has led to a backlog of orders and low production capacity, resulting in difficulty in shipping. Also, after the dyeing factory started working, everyone queued up for dyeing, and there was always someone who came first and arrived first. I can only say that the first few in the queue were lucky.

It is difficult to find workers and it is difficult for factories to recruit workers

According to the current situation, as for Suzhou and other The local government has implemented a road closure policy to isolate outsiders. Many outsiders cannot enter the city. Even outsiders who come into the city need to self-isolate at home for 14 days. I even heard that they have to pay for self-isolation, and they need to pay 200 yuan per day. In this way, 14 days of quarantine will cost 2800, which can be said to be a month’s salary for some migrant workers. Thinking of this, those migrant workers who want to work in soda will not suffer this disadvantage, and they should stay in their hometowns to avoid The risk of infection is eliminated and money is saved. It is precisely because of this that textile factories have difficulty recruiting workers!

Inventory backlog puts textile bosses under great pressure

Speaking of inventory, I believe this is a problem that exists in all textile companies. Piles of gray cloth are piled up. In the corner of the factory, let alone being hit by the epidemic this time, even cloth bosses in previous years would sigh when looking at these inventories. This year, affected by the epidemic, not to mention new orders, even these inventories are unknown where they are sold. The more inventory, the greater the losses. big. Fortunately, many textile companies have begun to receive new orders and process inventory online.

According to the China Silk City Network data monitoring company manufacturing inventory data, it can be seen that the inventory at the beginning of 2020 was about 37 days. By mid-January, the inventory reached about 39 days, and the inventory was only increasing. During the Chinese New Year period, inventory is rising due to the impact of the epidemic. It is also difficult for companies to sell inventory after they start operations.

After resuming work, the risk is very high

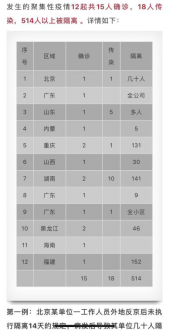

In recent days, some companies have resumed work (although some have not Weaving enterprises), but such densely populated places have increased the spread of the epidemic

The picture above shows that one person in a company in Guangdong was infected and the entire company was quarantined. In fact, the problem this caused was an indefinite delay, and no one knew when work would resume. It is because of this problem that some textile bosses are afraid and dare not resume work when they can apply for resumption of work.

Although work is resumed, we must be fully prepared to ensure that epidemic prevention measures are taken every day to minimize these risks.

This epidemic has caused major losses to major textile companies. After resuming work, they must hurry up to receive orders and produce to minimize the losses caused by the epidemic. However, some textile bosses said that 2020 It should be difficult too. </p