Recently, after the price increase last week, polyester filament has started a new round of price increase this week. Although the two increases are not large, they will have a certain impact on downstream weaving companies. On the 5th, after polyester prices generally rose, production and sales exceeded 100, and weaving manufacturers had good buying momentum.

In the recent stage, the volume of autumn and winter fabrics has increased, and printing and dyeing factories have picked up. Now coupled with the news that polyester yarns are generally rising, it seems that the textile market has a lot of vitality. The news can indeed play a very good role in boosting confidence, but the reality is cruel, and the actual market situation is not satisfactory.

The prices of raw materials rise and fall, and the profits of gray fabrics fall again and again

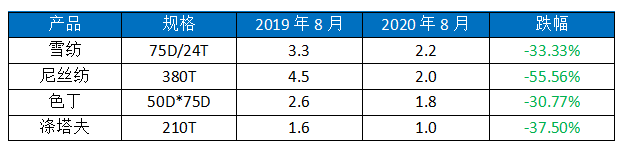

The price of polyester yarns happily increases, but the cloth boss can only cry silently. The cost has increased again. Although the price of polyester yarn is still at a historical low after the price increase, the current price of gray fabric cannot withstand the ups and downs. The price of gray fabrics on the market this year is very chaotic. The only unified tone is that it will only fall but not rise. However, there is no lower limit for the decline, and the price limit has dropped countless times. From the table below, it can be clearly seen that the price of gray fabrics has fallen sharply this year. Let me ask, where is the profit? Manager Qi of a weaving company that mainly produces polyester taffeta, taslan and other gray fabrics said: “This year’s sales volume is not much different from last year, but the profit is much lower. This year, most of them are selling goods, basically only 1- 2% profit.”

The demand for clothing has not improved significantly, and the demand for gray fabrics has not improved significantly. Price increases lack support

Recently, autumn and winter fabrics have begun to increase in volume, printing and dyeing factories have also begun to be busy, and everything is developing for the better. The editor believes that after the price increase of polyester yarn, the price of gray fabrics may be increased. However, after some market research, it was found that the cloth boss was eager to increase the price of gray cloth, but he could only hope for it and it was difficult to take action. On the one hand, due to the influence of the general environment, the demand for end-use clothing is weak. Even if the volume of autumn and winter fabrics is increased, the impact on the gray fabric market will be minimal. After all, the market is still oversupplied, and weaving companies are struggling to reduce inventory. The market is very competitive. Price war is currently the only bargaining chip for cloth bosses, and traders also choose to buy gray cloth at low prices. Under such circumstances, gray fabric prices naturally lose the confidence to increase prices.

The market price is chaotic, and gray fabrics are easy to fall but difficult to rise

On the other hand, the oversupply situation has caused the market inventory of gray fabrics to be too high. In order to withdraw funds, Many companies cut prices and sold off inventory. This phenomenon occurs every day, shouts of hawking occur one after another, and the market is already in chaos. Even if some companies raise the price of gray fabrics, they will be affected by some companies that continue to sell. They will lose their competitiveness in terms of price advantage and have to follow the trend. The price increase will naturally end in failure.

“It is too difficult to increase the price of gray cloth this year. The main reason is that the market price is too chaotic. Some manufacturers’ prices are so low that there is no bottom line. We cannot increase the price at all. Now most of the cloth in stock in the factory is High-end gray fabrics, produced with high-priced raw materials last year, are selling at a loss this year. Only some low-end conventional gray fabrics are basically sold out, and raw materials need to be purchased for weaving now, which may increase prices. But polyester prices If the price of gray fabrics rises by at least 1,000 yuan/ton, the price of gray fabrics may rise a little,” said Mr. Li, who produces imitation silk.

In the current textile market, not only prices are not rising, but inventory pressure has not been alleviated. The increased volume of autumn and winter fabrics is nothing more than a drop in the bucket, and the inventory of weaving companies is as motionless as a mountain. According to data monitoring from China Silk City Network, the inventory of water-jet and air-jet gray fabrics in Shengze area is still around 45 days old. The off-season is the off-season after all, and it is difficult to find a way to “go against the trend and go up”.

The domestic market lacks momentum and there is still trade The company has no orders to accept

Although the market has recently released news of increased sales of autumn and winter fabrics, onlyAlthough some orders have picked up, there are still companies that have no orders to take. The domestic sales market lacks the stamina to improve, and the overall order reception situation is average. The person in charge of an integrated industry and trade company that specializes in simulated silk said, “Currently there are no orders on hand, only some proofs and samples sent, and I don’t know when I can get real orders. The overall market is not good, mainly due to serious overcapacity, not It will be relieved in a while, so the recent market improvement is not obvious.” Resistance in the foreign trade market has increased, and export orders have been hit.

Foreign trade has also suffered a double blow, and orders have not recovered well. The global epidemic is still spreading, and the number of confirmed cases of COVID-19 in many countries is increasing, which has created greater resistance to the foreign trade exports of textile and clothing products. Recently, news came out that the Vietnam-EU Free Trade Agreement will come into effect, which will divert export orders and undoubtedly hit the foreign trade market again. There are many negative factors in the market, and the price increase of gray fabrics may be far away. However, there is still great hope for the market to improve. There is still a partial recovery in the off-season and there are still bright spots. I believe that with the arrival of the traditional peak season, the market will get better and better.

</p