In order to standardize product production and ensure product quality, on April 25, 2016, the National Standards Administration recently released the national standard “Outdoor Sportswear Jackets” (GB/T32614-2016). 【Oxford cloth】

It is reported that the standards released this time have made some changes in the safety, basic product performance and functional indicators of jackets. Regulation. It will play an active role in standardizing product production, ensuring product quality, and maintaining the health and safety of outdoor sports enthusiasts. At the same time, in order to protect children’s health, the standard also specifically stipulates safety requirements applicable to children. The new standards will be implemented from November 1st.

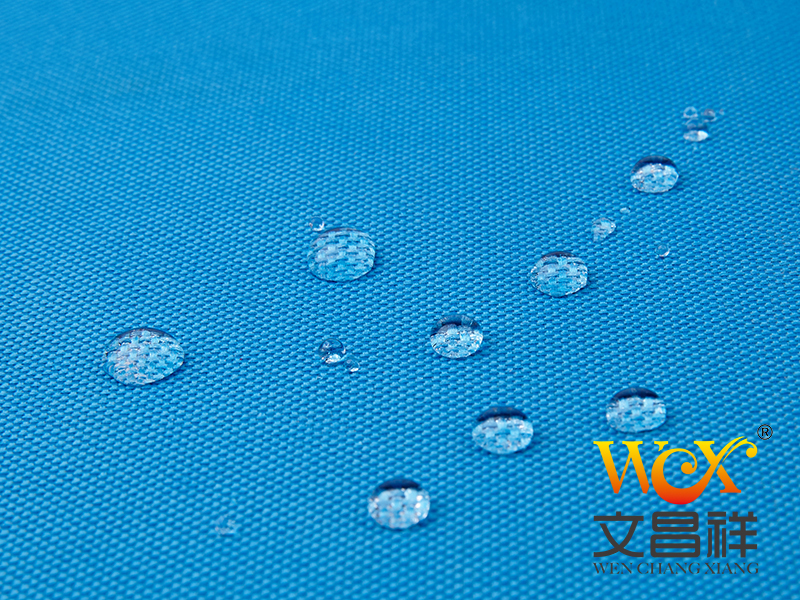

In order to ensure that the functional requirements of jackets are suitable for a variety of outdoor sports, the new standards divide the functional requirements of jackets into professional categories (Level I) and non-professional categories. Category (Level II). In terms of surface moisture resistance (meaning that water droplets falling on the fabric, such as dewdrops on a lotus leaf, will naturally slide off without leaving traces), the standard stipulates that the level of water staining before washing is level 4, and the waterproof performance is evaluated as “very good resistance to water droplets.” “Wetting performance”, in terms of hydrostatic pressure (meaning that the fabric can withstand the long-term action of high water pressure, but the inner layer does not absorb water and is not wet), the standard stipulates corresponding indicators for fabrics and fabric seams; in In terms of moisture permeability (sweat produced by the body needs to be discharged in time), the standard stipulates that the moisture permeability is 5000 for Class I products and 3000 for Class II products. In addition, in order to protect the health of children, the standard also stipulates safety requirements applicable to children. , such as children’s top drawstrings, children’s clothing rope safety requirements, etc. 【Tent Oxford cloth】

Most of the jacket products on the market use polyester, nylon and other chemical fibers. For fabrics, the waterproof effect can be achieved by applying water-repellent finishing on the surface of the fabric, coating or film finishing on the reverse side of the fabric.

When consumers need to wash and maintain their jackets, it is best to follow the product washing label prompts, use neutral detergent, and machine wash with a gentle washing cycle (also Can be hand washed gently). Before cleaning, you can use a small brush to clean local stains. After washing, you can use the drying method, which will help restore its waterproof and moisture-permeable properties. It is not recommended to use bleaching detergents such as chlorine bleach, strong spin-drying, high-intensity washing, dry cleaning, long-term soaking and other practices that weaken the waterproof and breathable performance of the product.

It is worth noting that after multiple washings of a jacket, its waterproof and moisture-permeable effect will be reduced accordingly, so if it is not necessary, the number of times the jacket should be washed can be appropriately reduced. [Oxford fabric for bags and bags]

Finally, the standard also stipulates the durability requirements for jacket products, including pilling and wear resistance. , tearing strength, seam strength at the back of trousers, etc., mainly considering that in general outdoor activities such as mountain climbing and traversing, various unexpected factors may cause scratches or damage to the clothing, thus affecting the functionality and aesthetics of the clothing. .

Suzhou Textile Co., Ltd.: www.wcxfz.com </p