UV-resistant Oxford fabric: polyester UV-resistant Oxford fabric, nylon UV-resistant Oxford fabric. Of course, anti-UV fabrics also include cotton, linen, silk and wool, polyester-cotton, nylon and other fabrics. These fabrics have good absorption and conversion capabilities for ultraviolet rays. Through reflection and scattering, all the ultraviolet rays absorbed by the fabrics are emitted, thereby preventing ultraviolet rays from harming human skin.

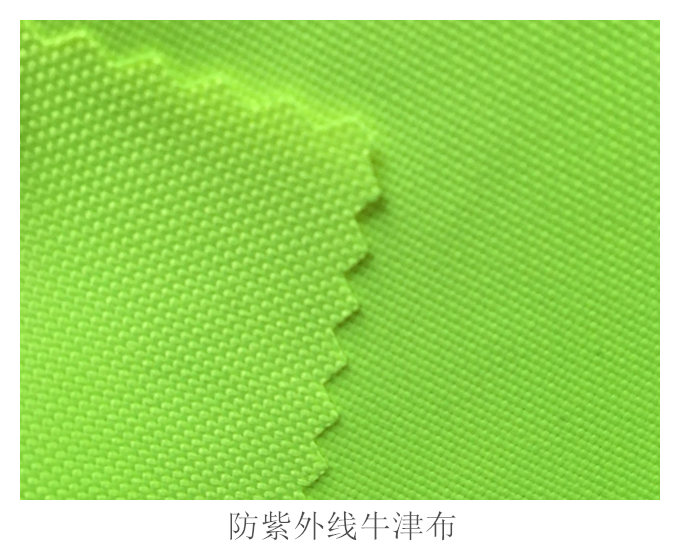

The picture below shows: UV-resistant fabric–600D Oxford cloth

Why does Oxford fabric need to be UV-resistant?

Ultraviolet rays from the sun not only cause textiles to fade and become brittle, but can also cause sunburn and aging of human skin, producing melanin and stains. In more serious cases, it can induce cancer and endanger human health. This is why we pay more and more attention to it.

The absorption of ultraviolet rays by the skin is related to its wavelength. The shorter the wavelength, the smaller the depth it penetrates into the skin, and the melanin pigmentation after irradiation is weaker; the longer the wavelength, the greater the depth it penetrates into the skin, and the stronger melanin pigmentation after irradiation. Due to the action of photochemical reactions, higher energy level photon flow can cause the denaturation of nuclear proteins and some enzymes in cells. Therefore, after being exposed to ultraviolet rays, it takes an incubation period of 6 to 8 hours before cell changes occur and symptoms appear, including dry and painful skin, epidermal shrinkage, and even blistering and shedding.

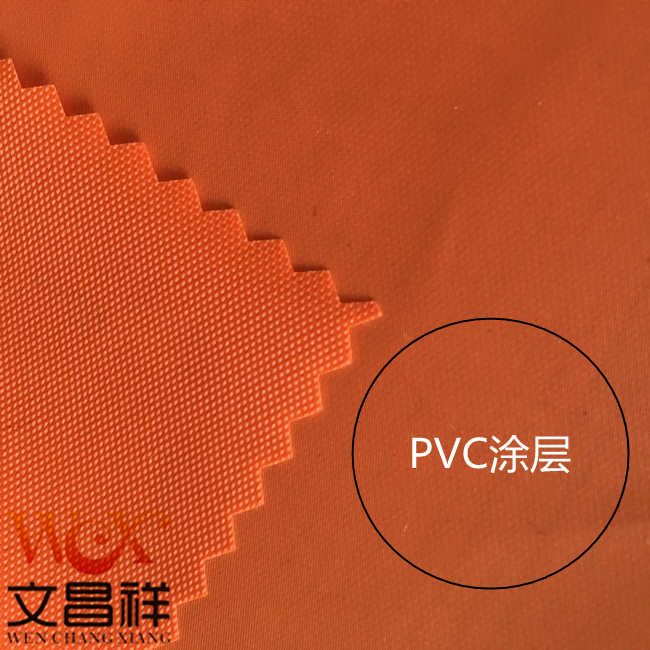

The UV shielding finishing process for fabrics is related to their end use. For example, as a clothing fabric, which has high requirements for softness and comfort when worn in summer, it is better to apply UV absorbers using the exhaustion method or padding method; if it is used as a decorative, household or industrial textile, its functional requirements are emphasized. The coating method can be used; for the anti-UV finishing of blended fabrics, from a technical point of view, it is better to use the exhaust method and the padding method, because this process affects the fiber performance, fabric style, hygroscopicity (water) and strength The impact is small, and it can also be carried out in the same bath as other functional finishing processes, such as antibacterial, deodorizing, water purifying, anti-wrinkle and other post-treatment finishing processes.

Make every meter of cloth with care – TextileUV-resistant Oxford cloth wholesalehttp://www.wcxfz.com

</p