Outdoor products, also known as outdoor equipment, are the equipment we need for various outdoor activities such as travel and adventure. It must be breathable, waterproof, UV-proof, anti-fouling, anti-static, tear-resistant, anti-bacterial and deodorant, windproof and warm, such as hiking bags, hiking shoes, tents, sleeping bags, etc. made of Oxford cloth.

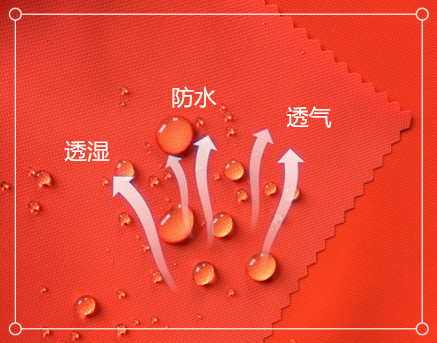

These performance requirements of Oxford cloth are relatively strict from the perspective of textile technology, such as waterproof and breathable functions, which are achieved using different technologies such as thickness, tightness, porosity, structural settings, and finishing of Oxford cloth. .

Antibacterial and deodorant properties: usually treated with antibacterial and deodorant chemicals, such as aloe vera, mugwort leaves, eucalyptus leaves, roses and other aromatic extracts with bactericidal effects, which are coated in porous organic microcapsules or porous The ceramic powder adheres to the fabric to achieve the purpose of durable antibacterial finishing.

The anti-fouling and easy-to-remove finishing process of Oxford cloth is achieved by changing the surface properties of Oxford cloth and greatly increasing the surface tension of Oxford cloth. The anti-fouling finishing process can not only prevent oil pollution, but also make Oxford cloth waterproof and breathable. It is generally called: “three defenses”.

Warmth: Warmth and lightness are special requirements for outdoor textiles. Its warmth retention can be achieved through a variety of technical means. Nano-modification or conventional modification of chemical fibers, such as adding ceramic powder; using far-infrared ceramic powder, adhesive and cross-linking agent to form a finishing agent to coat the fabric; according to the principle of bionics, the interior of the polyester fiber is It is made into a porous hollow shape, and the outside is made into a spiral curl shape to maintain the fluffiness of the fabric. The other is compounding, which is to combine two or more fabrics together.

The antistatic and radiation-proof finishing process of Oxford cloth is mainly achieved through two technologies: implanting conductive fibers (such as metal wires) into the Oxford cloth to make it conductive, electromagnetic wave shielding and radiation-proof. fabric; or use an antistatic agent with hygroscopic effect to coat the Oxford cloth.

To learn more about Oxford cloth, please consult textile customer service or call the hotline: 400-8380917.

</p