How did a piece of white Oxford cloth become a piece of multi-functional Oxford cloth with bright colors, diverse characteristics and wide application? What I want to share with you today are some waterproof and anti-static finishing processes that are often used in Oxford cloth.

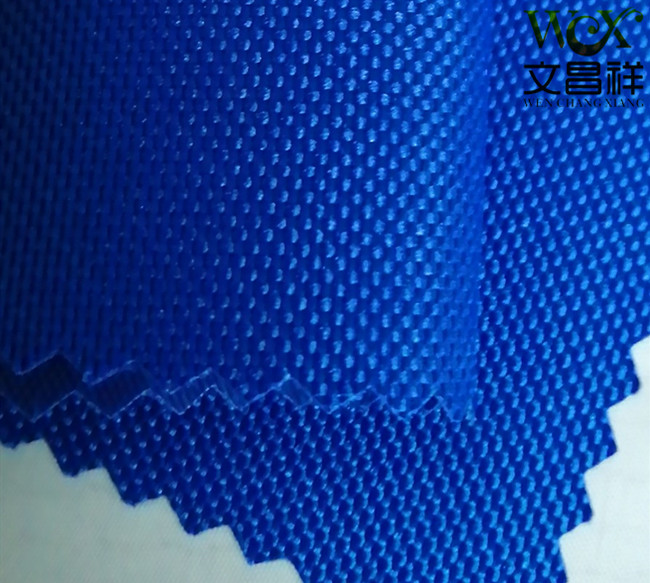

Dyeing process: As the name suggests, it is the method of coloring Oxford cloth. To beautify the appearance, improve the performance of Oxford cloth and meet the needs of consumers.

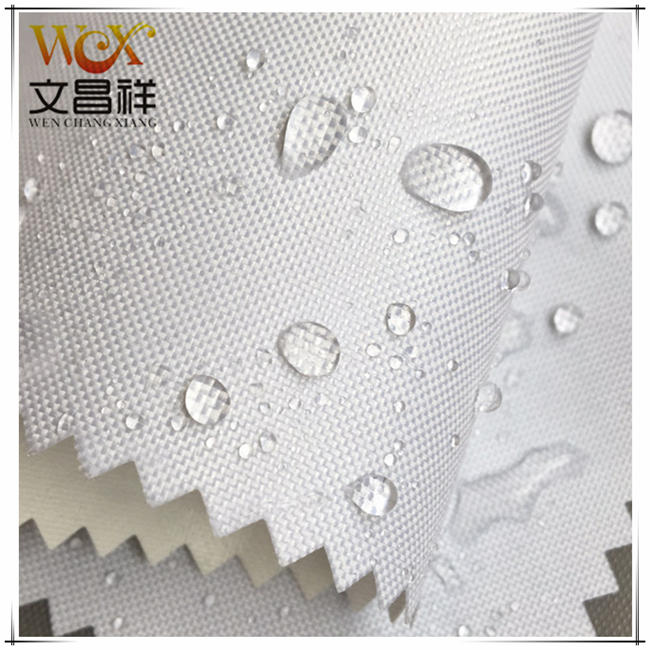

Waterproof coating process : Coating or bonding a layer of dry molecular material on the surface of Oxford cloth gives it unique waterproof function. The coating processing agent has certain adhesion and can form a continuous film. If hydroxyethyl cellulose, polyvinyl alcohol and other materials are added to the coating polymer material, the effect of being both moisture-permeable and waterproof can be obtained, which is called waterproof Oxford cloth.

Anti-static Process: a. Use highly hygroscopic polymer cations and anionic electrolytes to treat the Oxford cloth successively, and then heat and bake them to react with each other and fix the surface of the Oxford cloth; use polymers containing hydrophilic groups to treat the Oxford cloth , forming a hydrophilic film on the surface of the Oxford cloth; c. Use high-energy radiation, such as electron beam radiation or chemical initiator, to graft the Oxford cloth with vinyl monomers containing water-based genes to denature the fiber and improve Hygroscopic, can achieve durable anti-static effect.

To learn more about Oxford cloth, please consult textile customer service or call the hotline: 400-8380917. </p