Why does the same 600D Oxford cloth have different softness and hardness? It is because the finishing process of Oxford cloth affects its feel.

Stiff finishing

Stiff finishing uses a film-forming polymer material to make finishing slurry and pads it on the fabric to make it adhere to the Oxford cloth. On the surface, after drying, a film is formed to cover the surface of the Oxford cloth, giving it a smooth, thick, plump and stiff feel.

Soft finishing

One of the soft finishing methods is to use mechanical action to make the Oxford cloth feel softer. A three-roller rubber blanket pre-shrinking machine is usually used to appropriately reduce the operating temperature and pressure. By speeding up the machine, a softer feel can be obtained. If the Oxford cloth passes through multiple passive square cloth guide rods and then enters the soft rolling point on the calender for calendering, a smooth and soft feel can also be obtained, but this softness The finishing method is not resistant to washing. Currently, most use softeners for soft finishing.

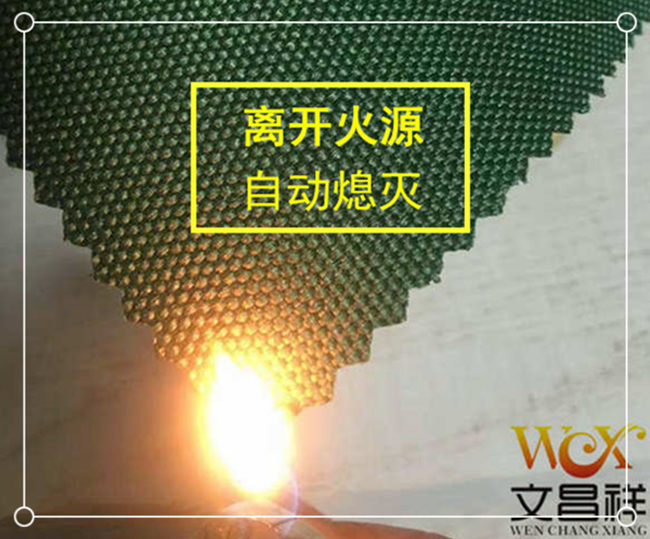

Textile waterproof oxford cloth, flame retardant oxford cloth, coated oxford cloth, camouflage oxford cloth, fluorescent oxford cloth wholesale, for more information, please contact customer service or call the hotline: 400-8380917

Part of the content of some of our articles comes from the Internet. If there is any infringement, please contact us and we will delete it as soon as possible.

</p