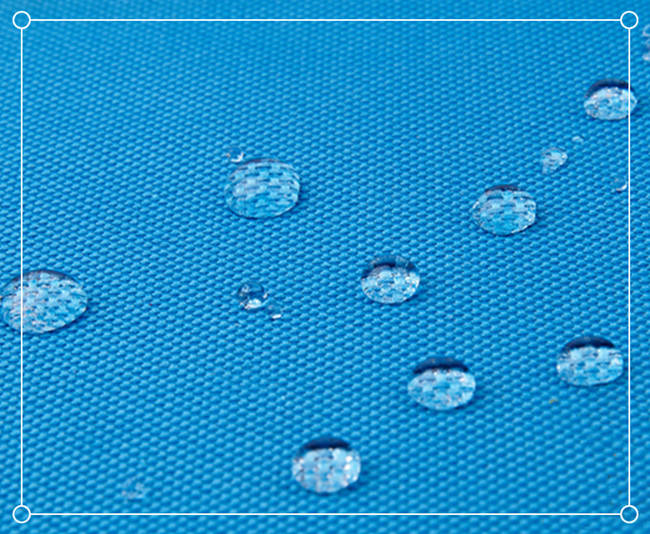

Waterproof is a common demand for outdoor Oxford cloth. The waterproofing of Oxford cloth is a post-processing process. After various post-processing processes such as waterproofing, PA, PU, Eucalyptus coating, PVC calendering, and foaming, the Oxford cloth has a fine texture, strong waterproofness, and richer and more diverse forms. .

Authentic 420D Oxford cloth is made of 420D polyester yarn in the warp direction and 420D polyester yarn in the weft direction, and is woven by a plain weave machine. It has been processed through multiple processes such as pre-shrinking, shaping, dyeing, PVC coating, and waterproofing agent treatment (the finishing is different for different uses). It has a soft and smooth feel, bright color, good waterproofing, strong and durable, good elasticity, not easily deformed, corrosion-resistant, insulating, crisp, easy to wash, quick-drying, durable and not easy to wrinkle, rich in colors, etc. Mainly used in bags, tents, awnings, awnings, medical rehabilitation equipment, etc.

Outdoor equipment The quality and function are mainly reflected in the textile fabric processing technology. Oxford cloth used for outdoor equipment has more design and processing steps than ordinary Oxford cloth and has multiple functions such as waterproof, windproof, breathable, water pressure resistance, warmth retention, perspiration, and UV protection. Therefore, it is necessary to control the production process of Oxford cloth fabrics. Quality is very critical.

Textile Master Ying Oxford cloth series products: waterproof Oxford cloth, flame-retardant Oxford cloth, coated Oxford cloth, fluorescent Oxford cloth, etc. If you are interested in or have questions about the products of Suzhou Textile Co., Ltd., please contact the online customer service on the web page, or leave a message. We will provide dedicated service to meet all your needs!

</p