PA coated Oxford cloth, that is, polyacrylate coating, is the most common and common coating at present. After coating, it can increase the hand feel, windproof and drape. Initially, PA coating was a waterproof product, but current products not only have waterproof, moisture-permeable, flame-retardant and other functions, but also have low-temperature and energy-saving features.

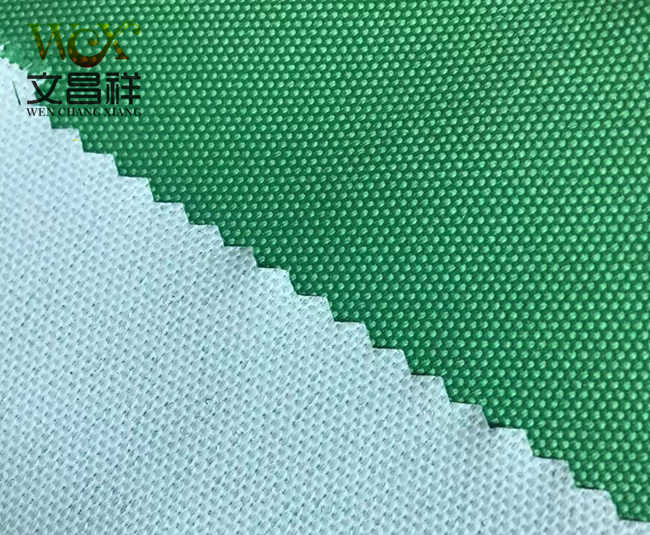

PA coating includes white glue coating and silver glue coating. The former refers to coating a layer of white on the surface of the fabric, which can increase the covering rate of the cloth surface, make it opaque and make the color of the cloth surface more vivid. PA silver glue coating is to apply a layer of silver-white glue on the surface of the fabric to make the fabric have light-shielding and radiation-proof functions. It is generally used in curtains, tents, and clothing.

PA coating finishing agents were initially mostly solvent-based products with excellent adhesion and water resistance. In order to improve the strength of the membrane, external bonding agents are often added. When it is combined with Oxford cloth, Oxford cloth can achieve higher water repellency and water pressure resistance.

Organized by PA Oxford cloth has both waterproof and moisture-permeable functions. Its waterproof and moisture-permeable mechanism relies on the formation of a large number of micropores during film formation. These pores are smaller than 2 microns, which can block water droplets (average diameter 100 microns), but allow water vapor molecules (average diameter 0.0004 microns) to pass through, thereby achieving waterproof and breathable properties.

Oxford cloth specifications: 1680D, 1200D, 900D, 600D, 420D, 300D, 210D, 150D, etc.

Oxford cloth functional classification: flame retardant Oxford cloth, waterproof Oxford cloth, PVC Oxford cloth, PU Oxford cloth, camouflage Oxford cloth, fluorescent Oxford cloth, printed Oxford cloth, composite Oxford cloth, etc.

</p